3D Printing vs. Traditional Manufacturing: Which Is Better?

The manufacturing world is changing fast. This change comes from new ideas in product development and printing services. If you need parts at an affordable price or want to create complex industrial applications, it’s important to know the differences between 3D printing and traditional manufacturing. With more demand for customization and quicker production times, businesses must choose which method fits their needs best. In this blog, we will look at how these manufacturing methods compare in efficiency, cost, and practicality.

Understanding 3D Printing

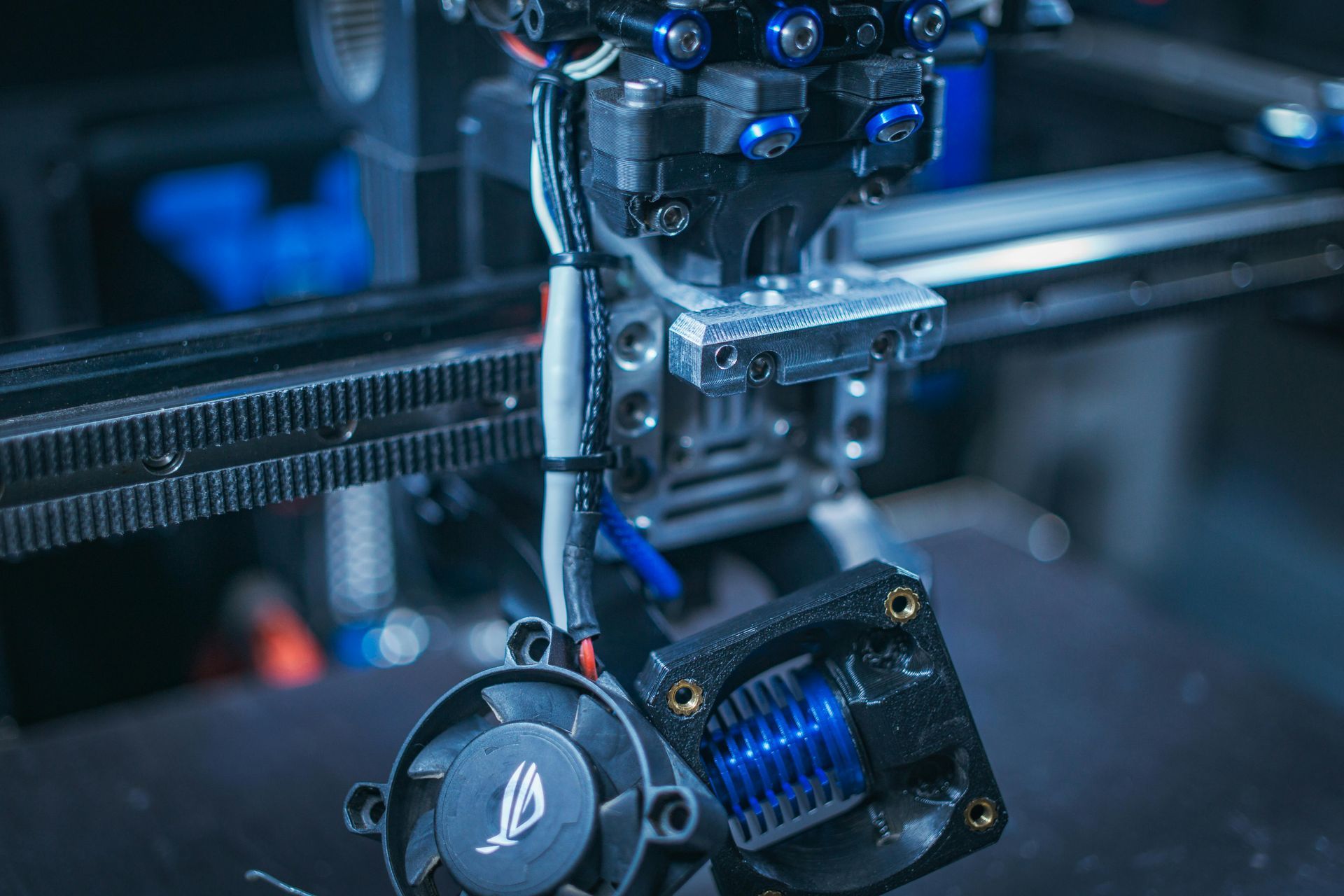

Three-dimensional printing has changed how products are made. It offers new ideas that traditional methods cannot match. With modern technologies like selective laser sintering (SLS) and fused deposition modeling (FDM), businesses can create high-quality prototypes and functional parts. They can use materials such as PLA, ABS, and PETG. Techniques like powder bed fusion allow for detailed shapes and custom fixtures. This means businesses in Phoenix, AZ, can get affordable prices and quick quotes for their production needs.

What Is 3D Printing?

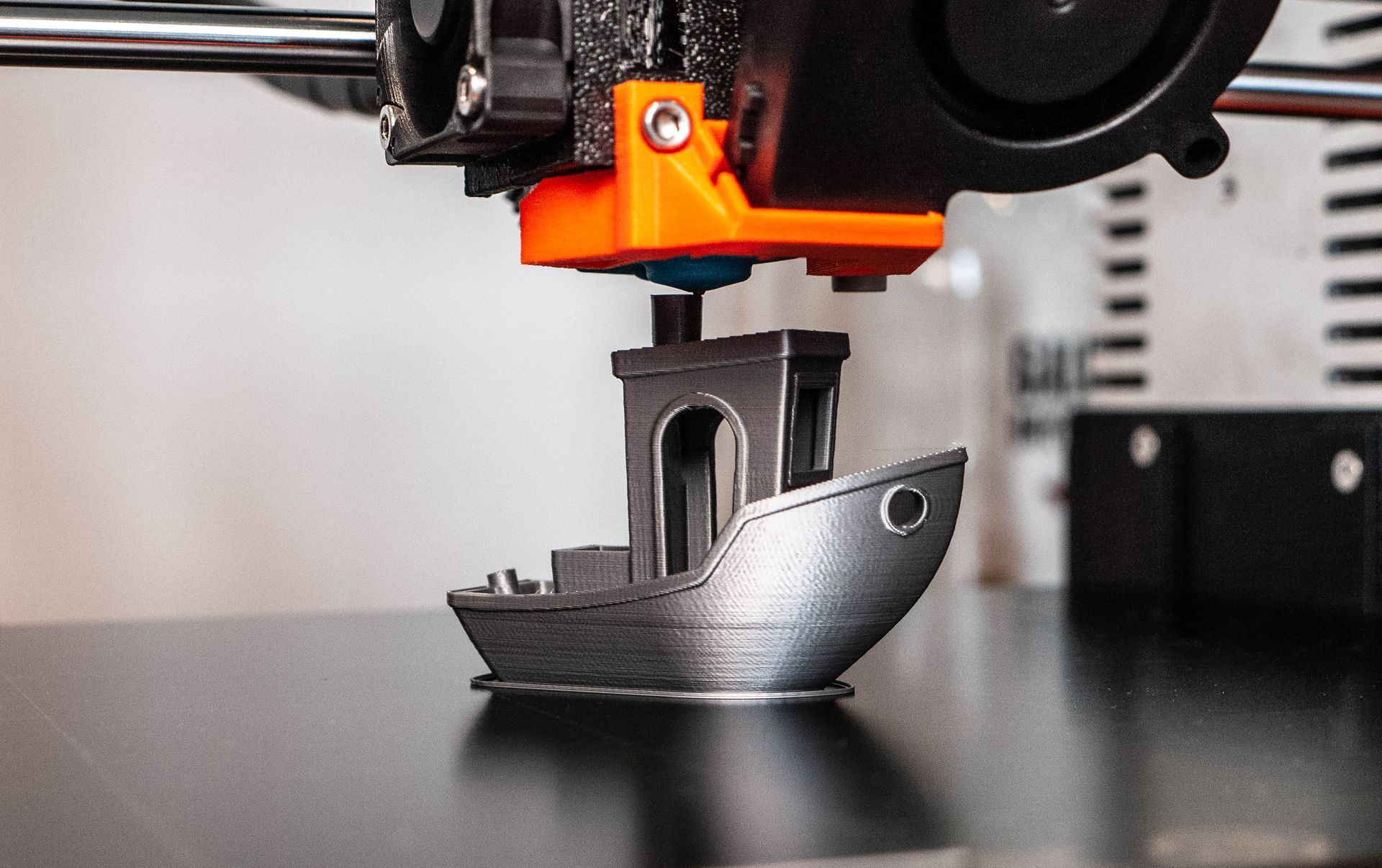

3D printing, or additive manufacturing, has changed how we make parts and products. This printing technology builds items layer by layer from digital blueprints. This method makes it easy to create detailed shapes with precision.

The greatness of 3D printing technology is in its flexibility. It can produce anything from simple prototypes to complex functional parts. This process reduces many limits of traditional methods. Areas like aerospace and healthcare gain a lot from its ability to make very specialized items. Visit By3Design 3D Printing: Benefits For Businesses to learn more.

Additionally, using user-friendly CAD software and simple setups, 3D printing Phoenix AZ By3Design services help businesses bring custom designs to life. Options like powder bed fusion, FDM, and SLA offer great outcomes designed for specific needs.

Key Technologies And Processes In 3D Printing

To understand 3D printing, it's important to look at its main technologies and processes:

- Powder Bed Fusion: This uses lasers to melt powdered materials layer by layer. This makes parts strong.

- Multi Jet Fusion (MJF): This uses heat with powder to quickly make functional parts.

- Selective Laser Sintering (SLS): This works well for low-run production and makes complex shapes using plastic powders.

Each process has its special uses, whether for detailed production parts, cost-effective prototyping, or industrial 3D needs. These methods show that printing technologies can help businesses be effective without losing high quality.

Exploring Traditional Manufacturing

Traditional manufacturing includes the methods and tools that have been used for many years to create parts in large amounts. Even though newer technologies like 3D printing services are becoming more popular, processes such as CNC machining still have an advantage for making production parts that need high precision.

Still, traditional methods usually require more detailed setups and take longer than their additive alternatives. By continuing to use proven techniques, manufacturers make goods for various industries, like automotive and medical. The following information shows its unique processes and tools.

Overview Of Traditional Manufacturing Techniques

Before printing technology, manufacturers relied a lot on CNC machining, SLA, and SLS to shape strong parts.

In CNC machining, parts get cut exactly to specifications with advanced tools. This makes it great for sectors like aerospace and robotics. SLA is used to create prototypes that have smooth finishes. These are perfect for consumer goods and advanced design displays. Likewise, SLS makes precision-engineered parts for high-demand fields like military and medical.

Even with the growth of 3D methods, traditional ways are still key because they are proven to be reliable and can scale up.

Common Tools And Equipment Used

Manufacturing needs the right equipment to make high-quality parts. In regular setups, tools like printers and CNC machines are very important.

Printers play a key role in both printing services and prototyping. With materials like PETG, ABS, and nylon, manufacturers create strong products that work well for industrial use. At the same time, CNC machines help refine details by carving or bending to meet specific specifications.

Also, traditional methods use injection molding and heat to keep shapes accurate on materials like metals and polymers.

Comparing Costs And Efficiency

The decision between traditional manufacturing and 3D printing services often depends on cost and speed. Traditional methods can save money for large production runs, while 3D printing is better for making prototypes quickly and producing custom shapes in a timely manner.

When it comes to efficiency, additive techniques help businesses change their production easily. Whether it’s saving money on large orders or making special designs, looking at these methods shows clear benefits that meet different project needs. Read more to learn about the financial and time factors involved.

Cost Analysis: 3D Printing vs. Traditional Manufacturing

| Factor | 3D Printing | Traditional Manufacturing |

|---|---|---|

| Set-Up Costs | Low, with not much tooling needed | High because of tooling and fixtures |

| Material Usage | Made to reduce waste | Uses more material, causing waste |

| Customization | Great for unique designs at an affordable price | Limited options for custom shapes |

| Volume Production | Best for small runs | Works well for big orders |

| Lead Times | Quick for prototypes and functional parts | Takes longer for product changes |

Your choice between the two should depend on your goals and budget.

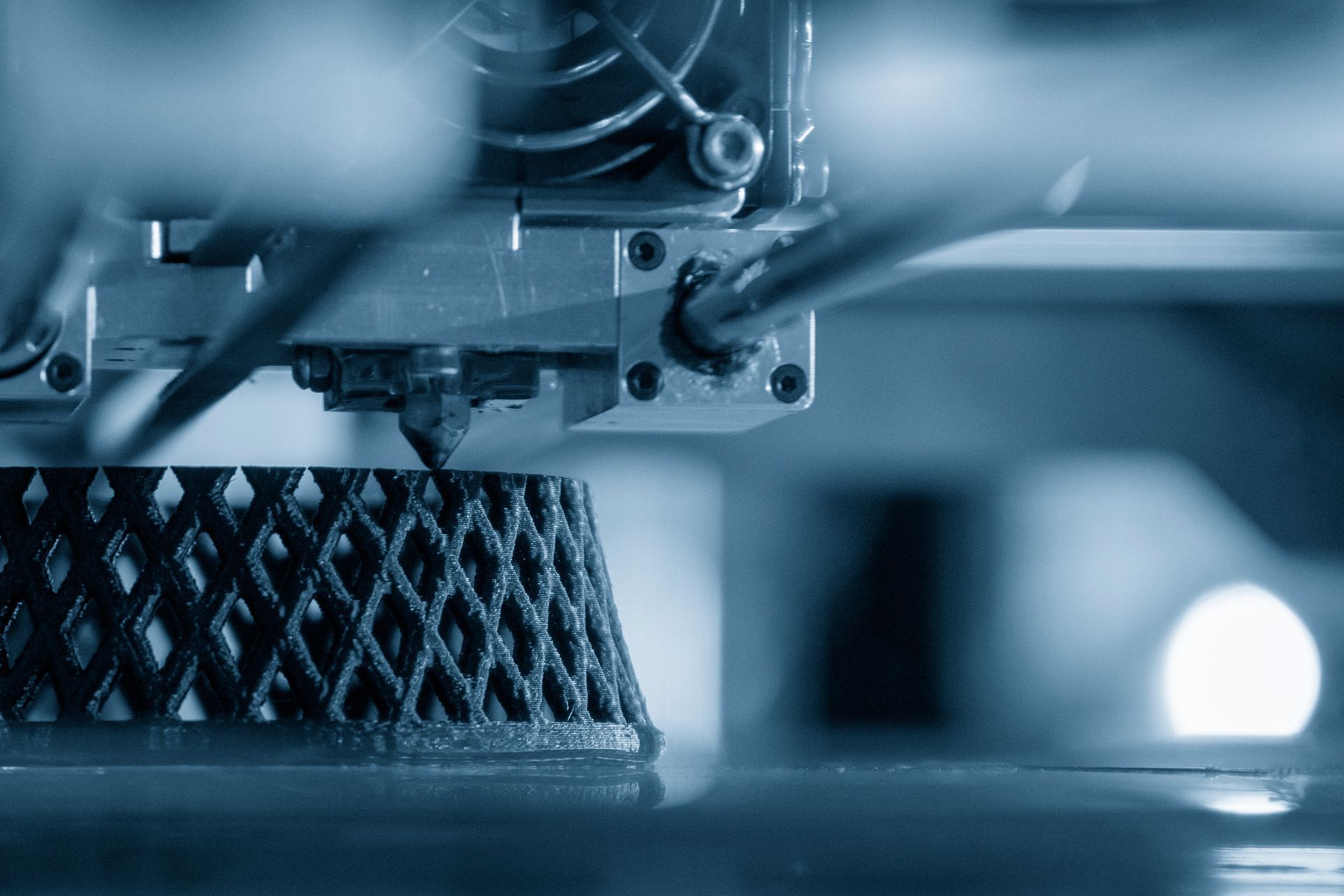

Time Efficiency: Which Method Is Faster?

Speed is very important when choosing a manufacturing method. 3D printing gives you great freedom by finishing projects in a timely manner and making high-quality prototypes overnight.

In the heart of Phoenix, AZ, the rise of 3D printing has transformed the manufacturing landscape. Businesses now have access to cutting-edge technology that streamlines production processes while enhancing creativity. This method not only simplifies complex designs but also allows for rapid iterations—essential in today’s fast-paced market.When assessing time efficiency, 3D printing stands out by providing significant advantages over traditional methods. With the ability to produce parts overnight, companies can pivot quickly in response to customer feedback or market demands.

Traditional methods can be good for making items in large amounts, but they often have slow setup times. 3D printing technology, like FDM and multi jet fusion, speeds things up. It makes designs quickly while still keeping fine details.

In the end, industries that need quick turnaround but still want complex designs benefit from using additive processes.

By3Design's Advice

At By3Design we suggest using 3D printing services if you want an instant quote for quick prototyping or special functional parts. Additive technologies, like SLS and MJF, help companies handle complicated industrial applications easily.

For accuracy, choosing 3D printing meets modern needs well. Traditional methods work for large orders, but they don't have the creativity that 3D printing brings in design and flexibility. Upload your designs, check out different materials, and get custom solutions in just a few minutes.

Conclusion

The choice between 3D printing and traditional manufacturing depends on what you need most. Both methods offer benefits and have their own uses. 3D printing is cost-effective and flexible with designs. Meanwhile, traditional manufacturing is reliable and scalable. By knowing the strengths and weaknesses of each method, you can make smart choices that fit your project goals. If you need help picking the right manufacturing process for your next project, feel free to

reach out. Your perfect solution is just a chat away!

By3Design Blog