Reverse Engineering With 3D Printing

How By3Design Brings Broken and Out-of-Production Parts Back to Life

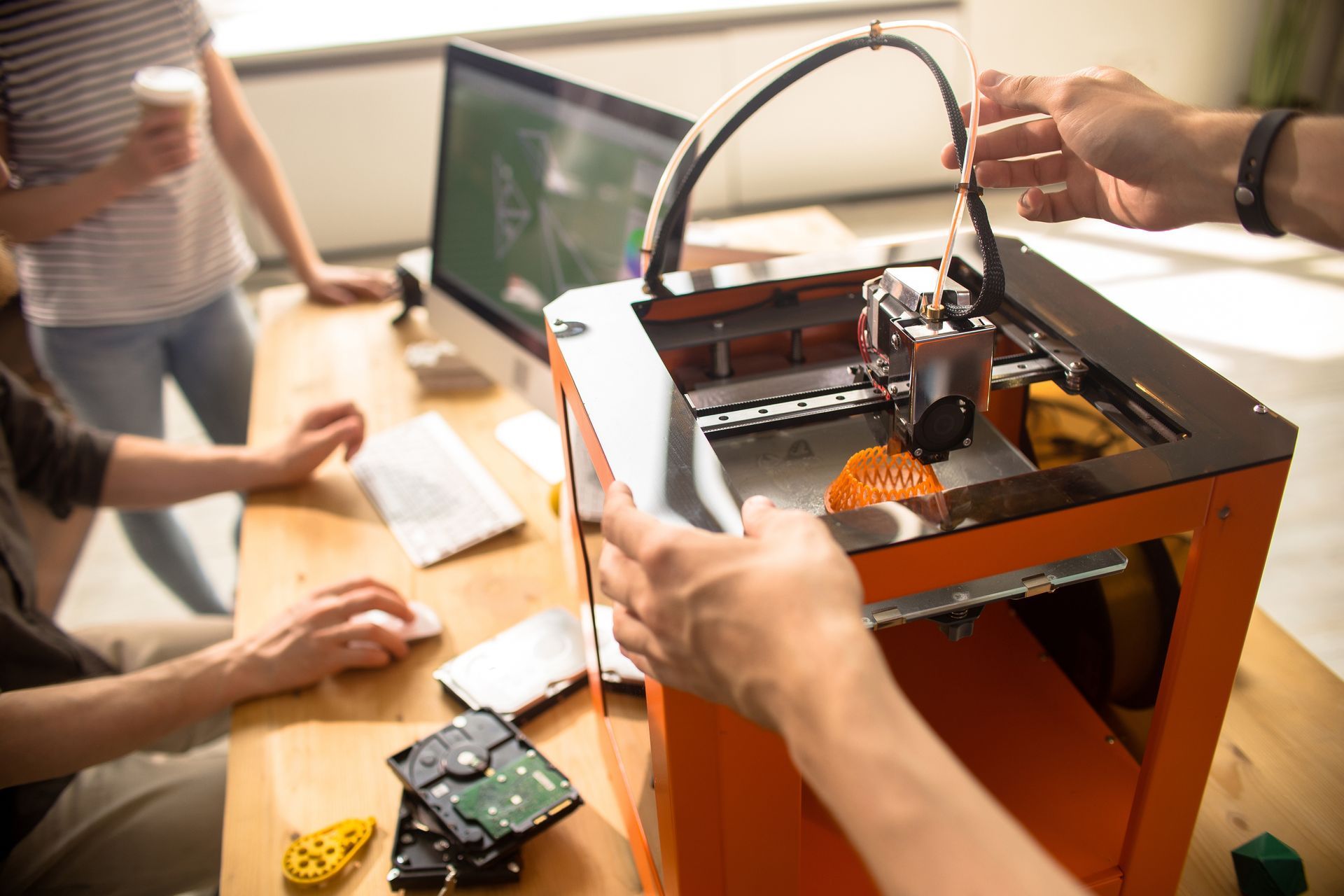

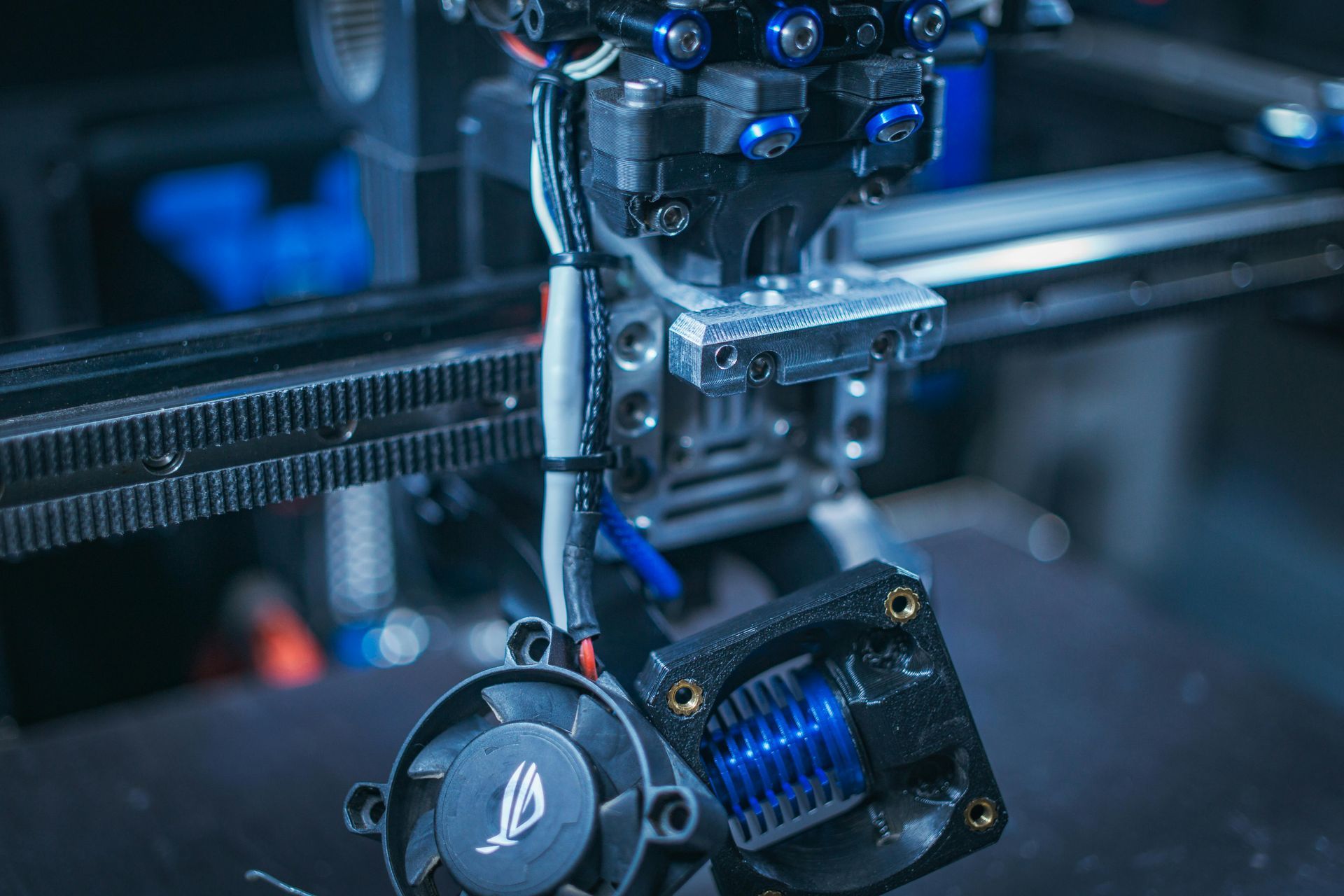

Technology continues to transform the way we solve problems, especially in manufacturing, product development, and repair. One of the most powerful tools leading this transformation is 3D printing. Combined with 3D prototyping, it has opened the door to innovative solutions once considered impossible or prohibitively expensive.

At By3Design, we specialize in helping businesses and individuals harness the full potential of

3D printing for custom projects. One of the most exciting applications of this technology is reverse engineering. Reverse engineering is the process of recreating a part by analyzing its design, function, and geometry. Whether you need a broken component replaced or a discontinued part reproduced, 3D printing makes it possible.

In this blog, we’ll explore what reverse engineering is, how 3D printing makes it more accessible than ever, and why By3Design is the go-to partner for creating accurate, functional reproductions of parts that are no longer available.

What Is Reverse Engineering?

Reverse engineering is the process of taking an existing product or part and analyzing its structure to reproduce it. Traditionally, this was time-consuming and required specialized equipment, detailed manual measurements, and expensive manufacturing methods.

With 3D prototyping and modern 3D printing, reverse engineering has become faster, more precise, and far more cost-effective. By scanning or modeling a broken or outdated part, a new version can be designed digitally and then reproduced using high-quality materials.

Why Reverse Engineering Matters

Every day, individuals and businesses face the challenge of broken or obsolete parts. Consider these scenarios:

- A homeowner needs a replacement component for an appliance that’s no longer manufactured.

- A manufacturer has machinery that works perfectly except for one part that’s cracked, worn out, or discontinued.

- A car enthusiast is restoring a classic vehicle but can’t find a specific bracket, knob, or clip.

In all these cases, reverse engineering powered by 3D printing offers a practical solution. Instead of retiring equipment or abandoning a project, you can recreate the missing or damaged part quickly and affordably.

The Role of 3D Printing in Reverse Engineering

So, how does 3D printing make reverse engineering possible? The process typically involves these steps:

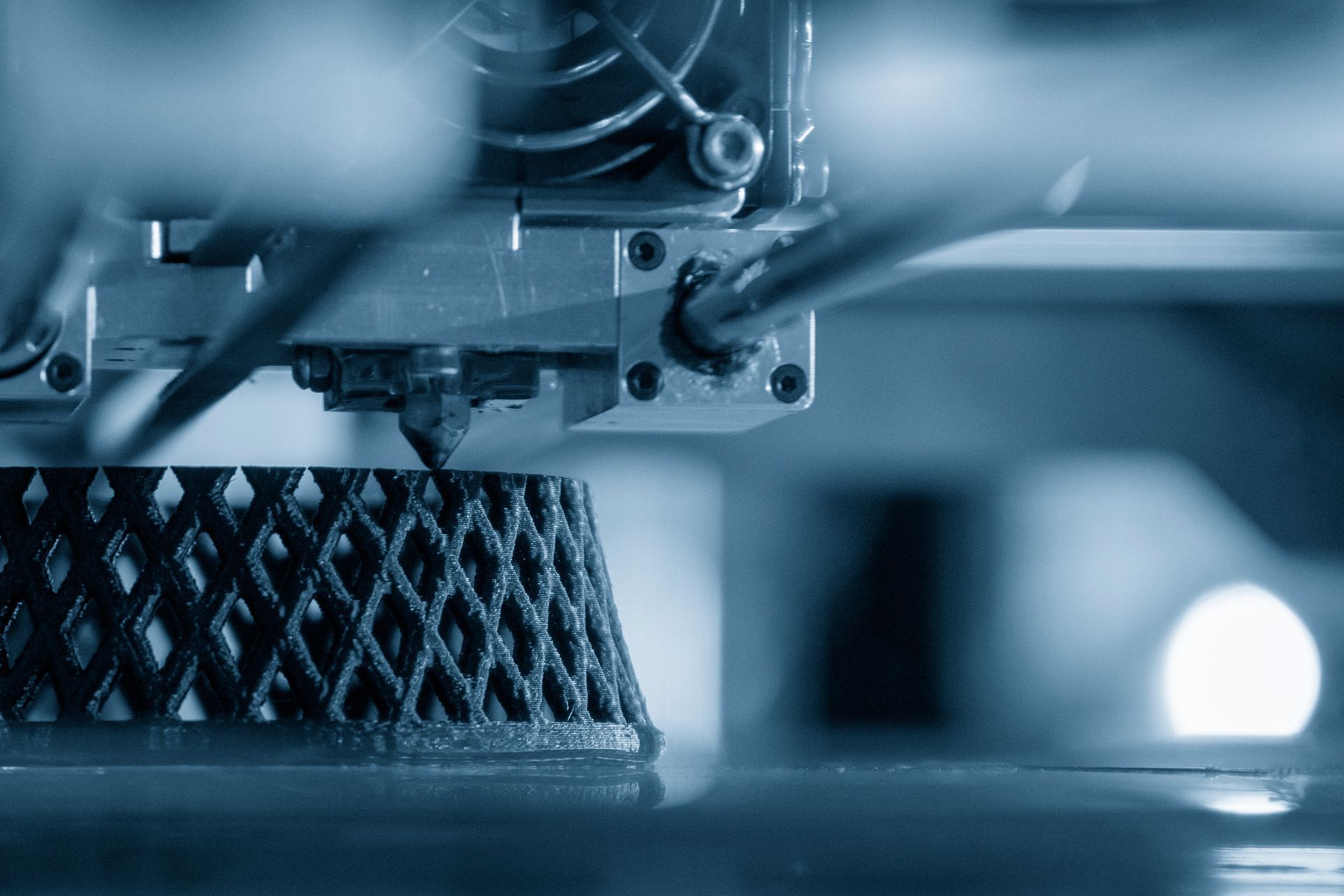

1. Scanning or Measuring the Part

If the original part is still available, even if it’s damaged, it can be scanned with 3D scanning equipment or carefully measured to create a digital model.

2. Digital Modeling

Using CAD (Computer-Aided Design) software, the part is recreated digitally. This step allows for design improvements if needed, such as reinforcing weak areas or optimizing for better performance.

3. 3D Prototyping

Before producing the final version, 3D prototyping can be used to create a test model. This prototype ensures that dimensions are correct and the part functions as intended.

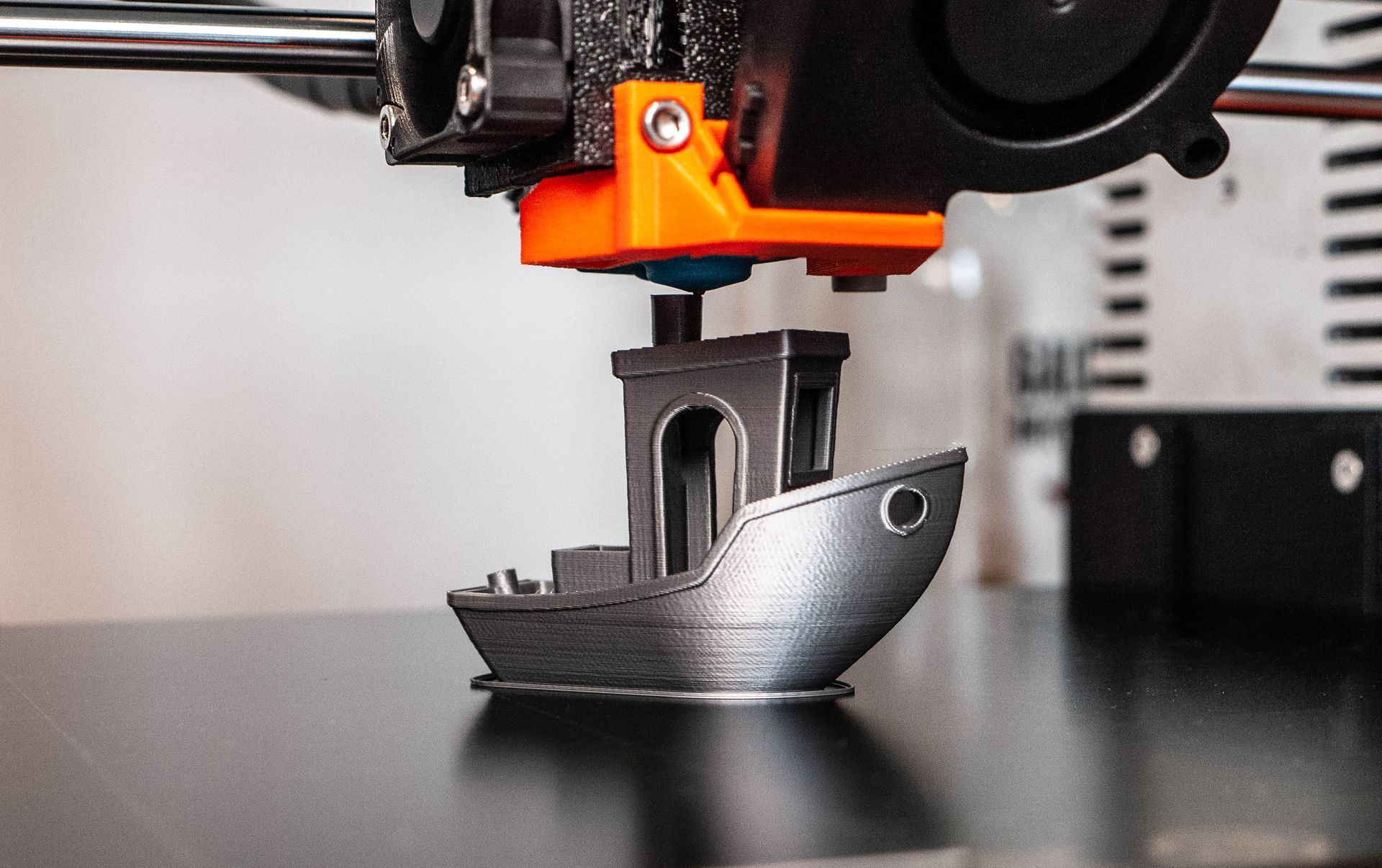

4. Final 3D Printing

Once the design is confirmed, the final part is produced using 3D printing technology. Depending on the requirements, parts can be printed in plastics, resins, or even metal composites.

Benefits of Reverse Engineering with 3D Printing

Working with By3Design to reverse engineer parts through 3D printing offers a range of advantages:

- Cost Savings – Avoid replacing entire machines or systems by simply reproducing one part.

- Speed – 3D printing dramatically reduces production time compared to traditional manufacturing.

- Customization – Digital modeling allows modifications or improvements to be added during reproduction.

- Accessibility – Even one-off parts can be created affordably, eliminating the need for bulk orders.

- Sustainability – Keep existing equipment running longer and reduce waste by replacing parts instead of discarding whole machines.

Real-World Applications of Reverse Engineering with 3D Printing

At By3Design, we’ve seen firsthand how reverse engineering solves problems across industries. Some common use cases include:

- Manufacturing: Replacing worn machine components without expensive factory reorders.

- Automotive: Restoring classic or rare vehicles with parts that are no longer sold.

- Consumer Products: Reproducing broken appliance knobs, handles, or latches.

- Medical Equipment: Creating replacement parts for older equipment still in use.

- Architecture & Design: Replicating decorative features for restoration projects.

By3Design’s Approach to Reverse Engineering

When you work with By3Design, you get more than just a part reproduction, you get a complete solution. Our process is tailored to deliver accuracy, durability, and efficiency:

- Consultation – We review your part and determine the best approach for reverse engineering.

- Scanning & Modeling – We create a precise digital model using 3D scanning or CAD software.

- 3D Prototyping – We test the part with a prototype to ensure accuracy and fit.

- Final 3D Printing – We produce the final part using the best materials for your application.

- Quality Assurance – Every finished piece is inspected for performance and reliability.

This step-by-step process ensures that every part we produce meets your expectations.

Why Choose By3Design?

There are many companies offering 3D printing, but By3Design stands out for several reasons:

- Expertise – Our team has extensive experience in 3D printing and 3D prototyping, giving us the knowledge to handle even complex projects.

- Precision – We use advanced tools to ensure every part is accurate to your specifications.

- Flexibility – From one-off parts to ongoing production, we scale our services to fit your needs.

- Innovation – We don’t just copy parts, we help you improve them.

- Customer Focus – At By3Design, we pride ourselves on communication, transparency, and delivering results that solve real-world problems.

The Future of Reverse Engineering with 3D Printing

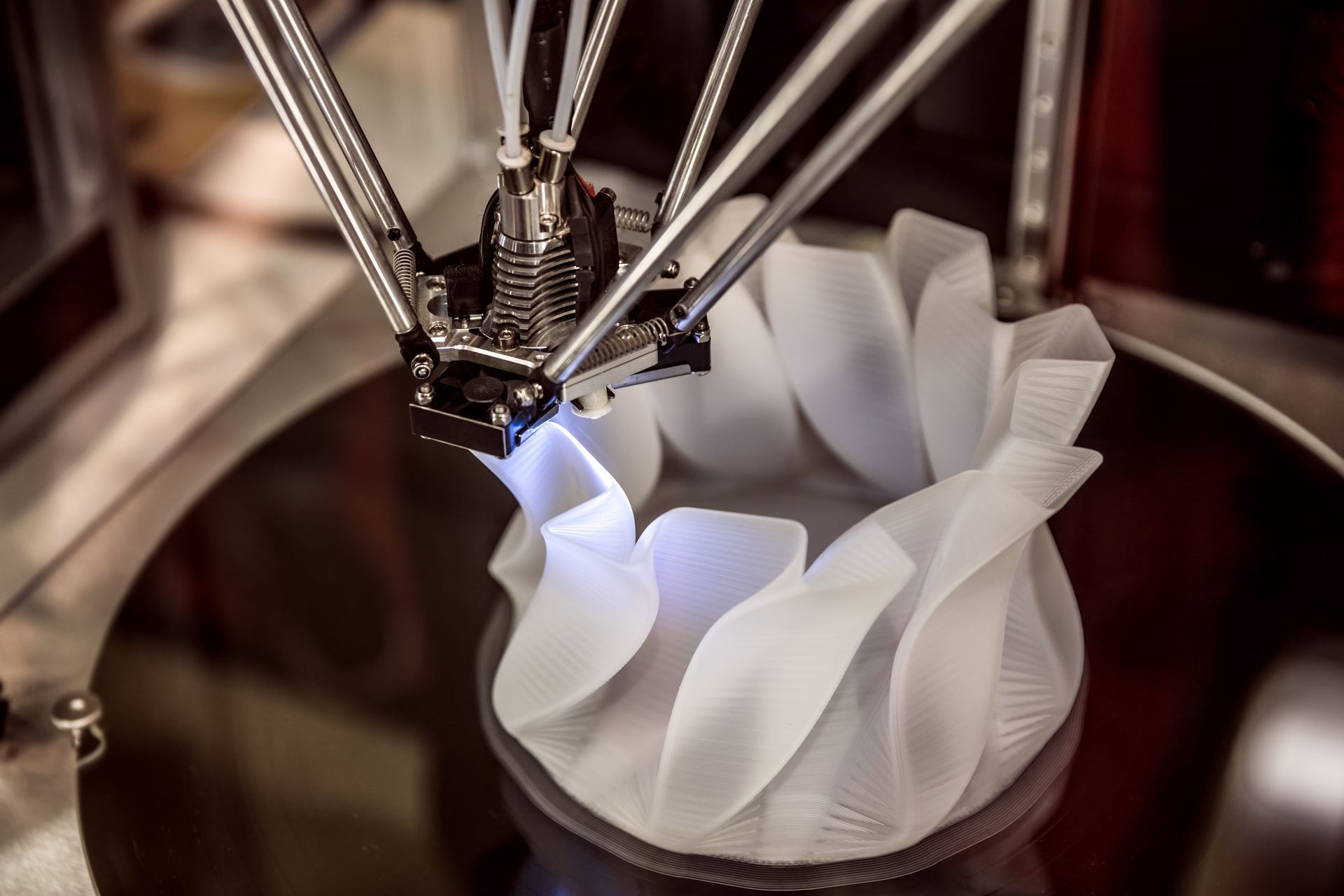

As 3D printing technology continues to advance, the possibilities for reverse engineering will only expand. Stronger materials, faster print speeds, and more precise scanning will make it even easier to reproduce complex parts.

Businesses that embrace these innovations today will have a competitive edge, saving money, reducing downtime, and keeping equipment operational long after manufacturers stop making replacement parts.

Getting Started with By3Design

If you have a broken part or need to reproduce something that’s no longer manufactured, By3Design is here to help. Our reverse engineering process using 3D printing and 3D prototyping ensures accurate, durable, and cost-effective solutions tailored to your needs.

Don’t let a single broken part hold back your project, machine, or restoration. With By3Design, you can bring it back to life, better than ever.

Conclusion

Reverse engineering with 3D printing is changing the way we solve problems. From one-of-a-kind appliance knobs to critical machine components, no part is too unique to reproduce. With 3D prototyping, improvements can be made along the way, ensuring parts are not only restored but optimized.

At By3Design, we combine expertise, advanced technology, and a passion for innovation to deliver parts that work when you need them most. You can always trust us to keep your projects moving forward.

If you’re ready to explore reverse engineering with 3D printing, contact By3Design today. Together, we’ll take what’s broken, outdated, or discontinued and make it whole again because the only limit is your imagination.

By3Design Blog