How Modern Businesses Are Leveraging 3D Printing

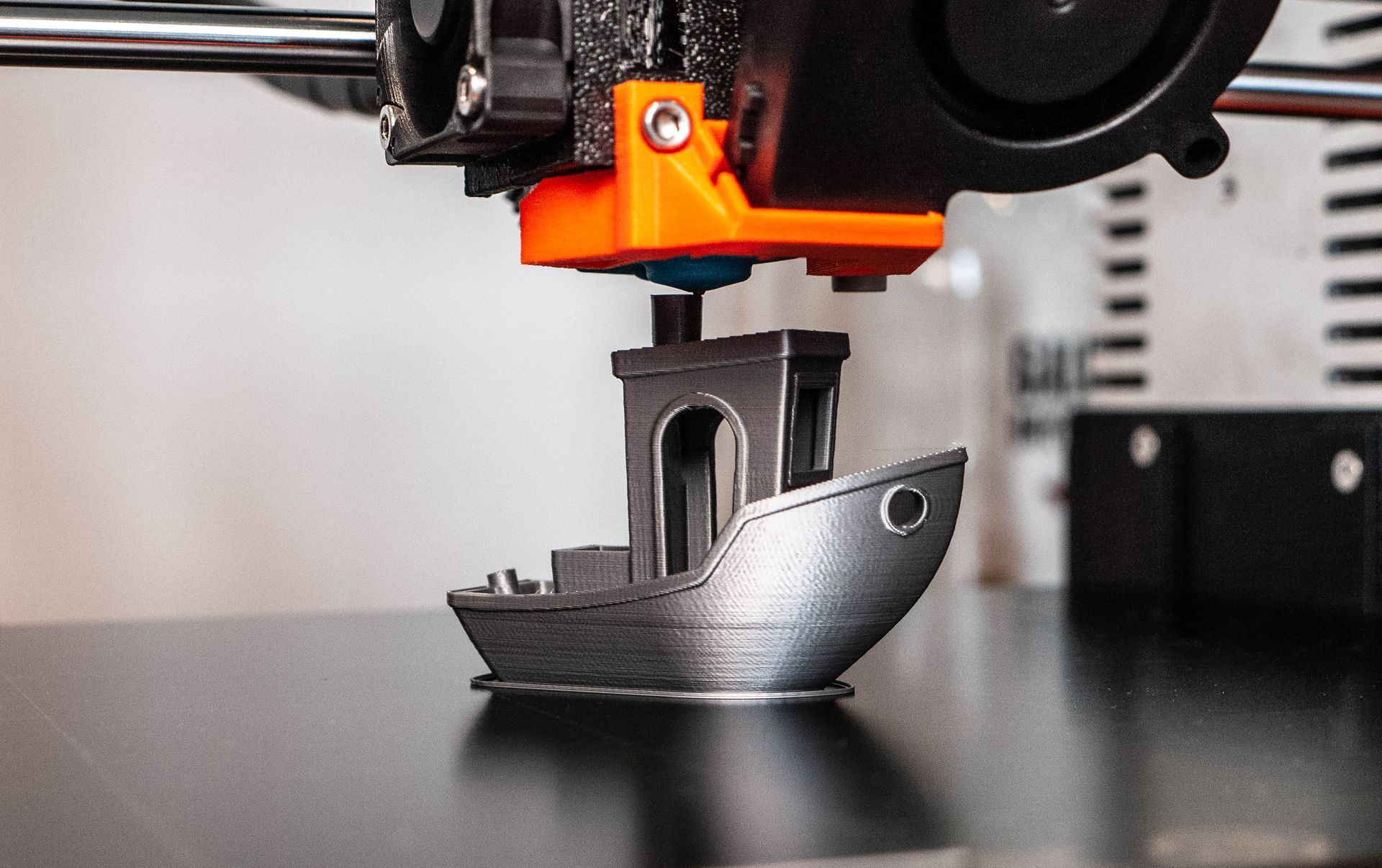

The rise of 3D printing in Phoenix is changing the way that people work and make things. It helps businesses move good ideas from plans to real objects much faster. Now, it is easier to work on rapid prototyping and making strong, durable products. This way, you can find new solutions, no matter what your needs are. The printing methods such as SLA, MJF, and FDM adapt to your unique specifications. Phoenix is now a place that is known for new and high-tech printing services. Many people and companies in the city now use rapid prototyping to get work done quickly and well. Let’s see how this technology is making things better for everyone.

Key Industries In Phoenix Benefiting From 3D Printing

Phoenix is becoming one of the top places for industries using 3D printing. Companies from many fields are now turning to this new way of making things. They use it for rapid prototyping, which helps them get new ideas out fast. The printing processes, like FDM and SLA, make it easy to meet complex needs and to make sure every part is just right. You can use these for both one-off prototypes and big batches, so they work well for many jobs.

Sectors such as aerospace, healthcare, automotive, and architecture now get tailor-made parts using 3D printing. This helps them hit tight specifications on every project and finish work on time. By using SLA and FDM printing, these businesses save money and improve how things work. Now, let's look at how companies in Phoenix are getting the most out of rapid prototyping and new printing technologies. Explore The Growing Demand For 3D Printing In The Tech Industry for more information.

Aerospace and Automotive Innovations

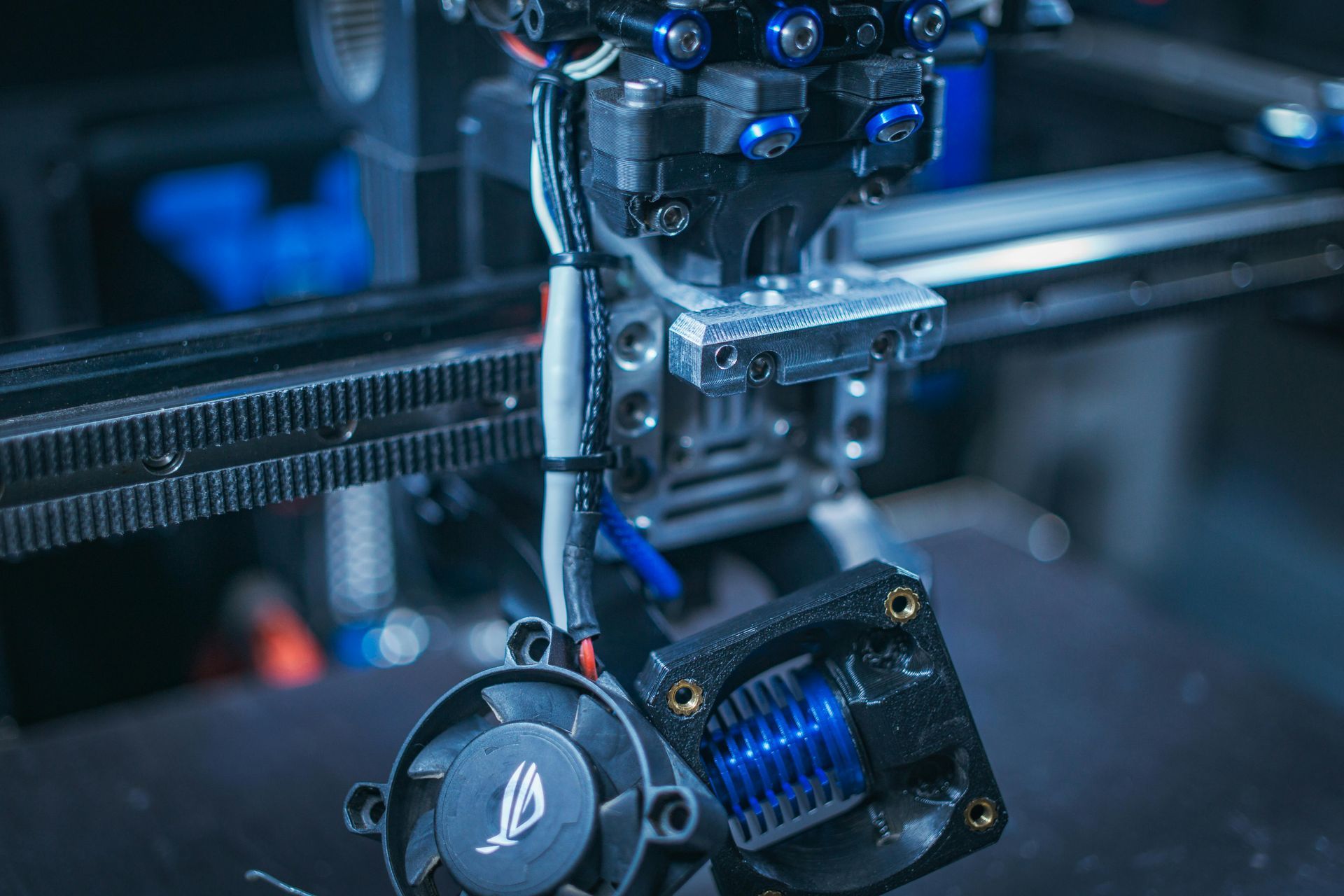

Phoenix’s aerospace and automotive industries are growing fast with the use of rapid prototyping technologies. In aerospace, 3D printing is changing how parts and prototypes are made. SLS and MJF are two printing processes that help get the right size and strength. These methods let you meet the high specifications needed for parts that must be very precise and strong.

Automotive makers in Phoenix also get a lot from these new rapid prototyping solutions. FDM lets them make parts with complex shapes. They use it to build strong assemblies, covers, and other fixtures, whether it is for testing or for real use. Materials like Nylon and ULTEM give the needed strength and the flexibility to handle pressure.

On top of that, Selective Laser Sintering, or SLS, makes it possible to produce small amounts of finished automotive parts. The use of these rapid prototyping technologies in Phoenix means the aerospace and automotive industries can bring new things to the market more quickly, make things that work better, and keep improving how they build everything.

Healthcare Advancements With Custom Medical Devices

Phoenix’s healthcare industry is moving ahead with custom medical devices made by 3D printing. Rapid prototyping helps doctors and others in healthcare design devices that fit patient needs using CAD to follow the right specifications. This lets them make devices that work for each person.

There is a wide range of products made by these methods. It goes from prosthetics to one-time-use electrical parts. Technologies such as SLA printing stand out for making smooth and very detailed prototypes with strong and durable materials. This makes SLA a good option for the look and function of medical uses. On top of that, new printing options like MJF give the mechanical strength needed for final surgical tools and items like diagnostic models. They are known for keeping their strength and fine details in every direction.

Doctors and others can also use many different materials, such as clear and tough resins. They are able to choose the right one to give better results for patients. The power to try new ideas with 3D printing is helping Phoenix be a leader in health technology and the way medical equipment is made.

Automotive And Transportation

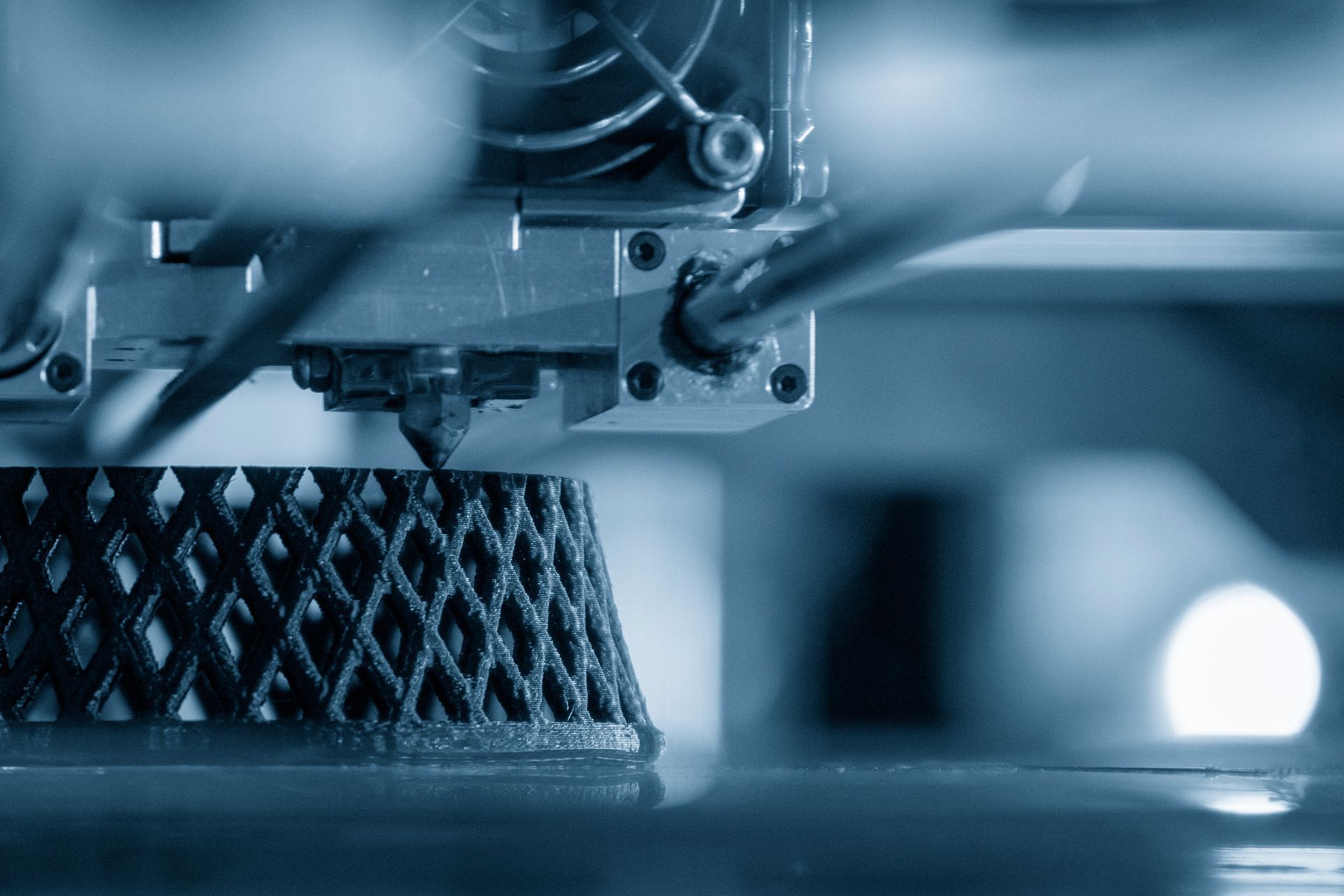

In Phoenix, the automotive and transportation sectors are making use of printing technologies like FDM, SLA, and SLS to help create new designs and products. FDM is a go-to for printing fast prototypes because it is both quick and affordable. This process lets manufacturers make durable parts with complex shapes, like cable strain reliefs or mechanical pieces, using materials such as PLA or ABS.

With SLA in the picture, companies now have a way to see and test how new designs will look and work before they decide to make them in large numbers. The accuracy SLA offers helps to make models that match the final pieces, which is great for doing prototyping or when only a small run is needed.

When companies need strong printed parts for cars or transport that will be used in real life, SLS comes in handy. This method gives both strength and the chance to change designs as needed. Because 3D printing Phoenix makes it possible to update designs and deliver parts fast, the automotive and transportation industries in Phoenix are finding new ways to take on production problems with durable solutions.

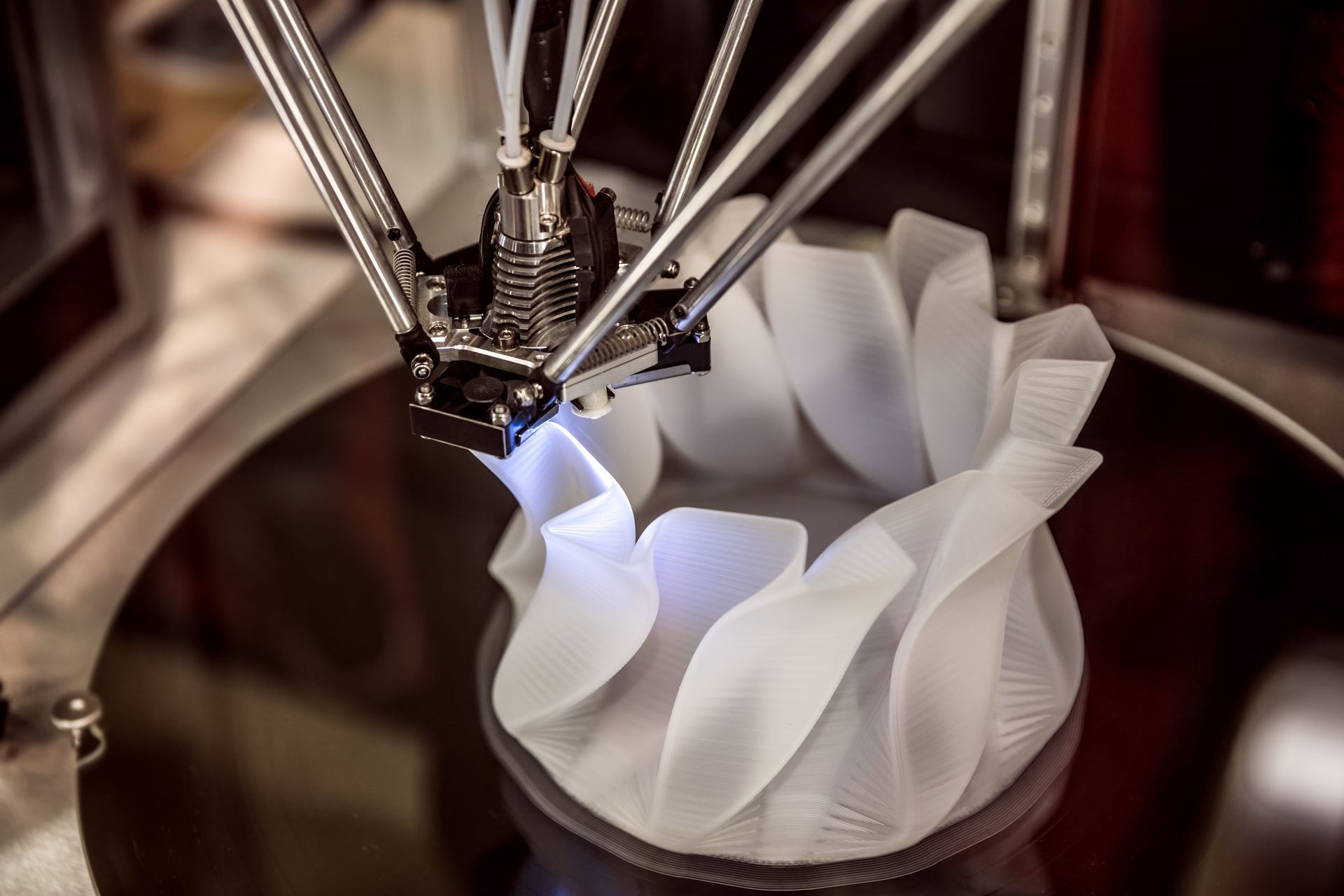

Architecture And Construction

Phoenix’s construction and architectural industries are seeing big benefits from 3D printing. With SLA and MJF, firms in Phoenix can make scaled models that show every detail of a design. You get visual clarity for all your ideas. From full city layouts to the inside of an office, SLA uses special resins to match different specifications with high accuracy.

For making small batches, SLS is a good way to produce durable parts. These can be things like strong jigs or working prototypes. Some companies in Phoenix use MJF printing to make sturdy items like jackhammer parts. These parts have good mechanical features and can take a lot of use.

These 3D printing technologies in Phoenix, like SLA and MJF, help lower costs and speed up the process. This is important, whether you need something for a large building project or just one piece. Phoenix builders now use printing to break new ground and finish things faster and better than before.

Consumer Products And Retail

In Phoenix, 3D printing helps product businesses make new prototypes and ready-to-sell goods. The use of MJF is very common here. It brings strong and accurate designs, like the kind you need for things such as electronic housings.

On the prototyping side, shops choose FDM steps to try out small product ideas. These can be changed by color and also have shapes that are different or tricky to make. When they use materials like ABS or Nylon, these things can be strong and bend without breaking. They can look and be used much like the items people use every day.

Also, SLA printing is a favorite way to make products people want to see, like jewelry types and home decor items. These samples get attention. Mixing what customers want with what actually works best has helped Phoenix shops offer new customer-driven ideas that really stand out in printing.

How By3Design Is Revolutionizing 3D Printing For Businesses In Phoenix

By3Design stands out in Phoenix by giving top-quality 3D printing services to local businesses. They are good at meeting many different needs, from aerospace and automotive to healthcare and products for people to use at home. Their work is known to be precise and of high quality.

The team works with printing methods such as SLA, MJF, and FDM. They help with rapid prototyping and create strong, durable items. By3Design is quick, so the results match customer specifications and also arrive on time. Many people and companies in Phoenix go to By3Design because they help push new ideas and make them real. With By3Design, turning plans into something you can use is easier for all of us.

Customization And Design Options Offered By By3Design

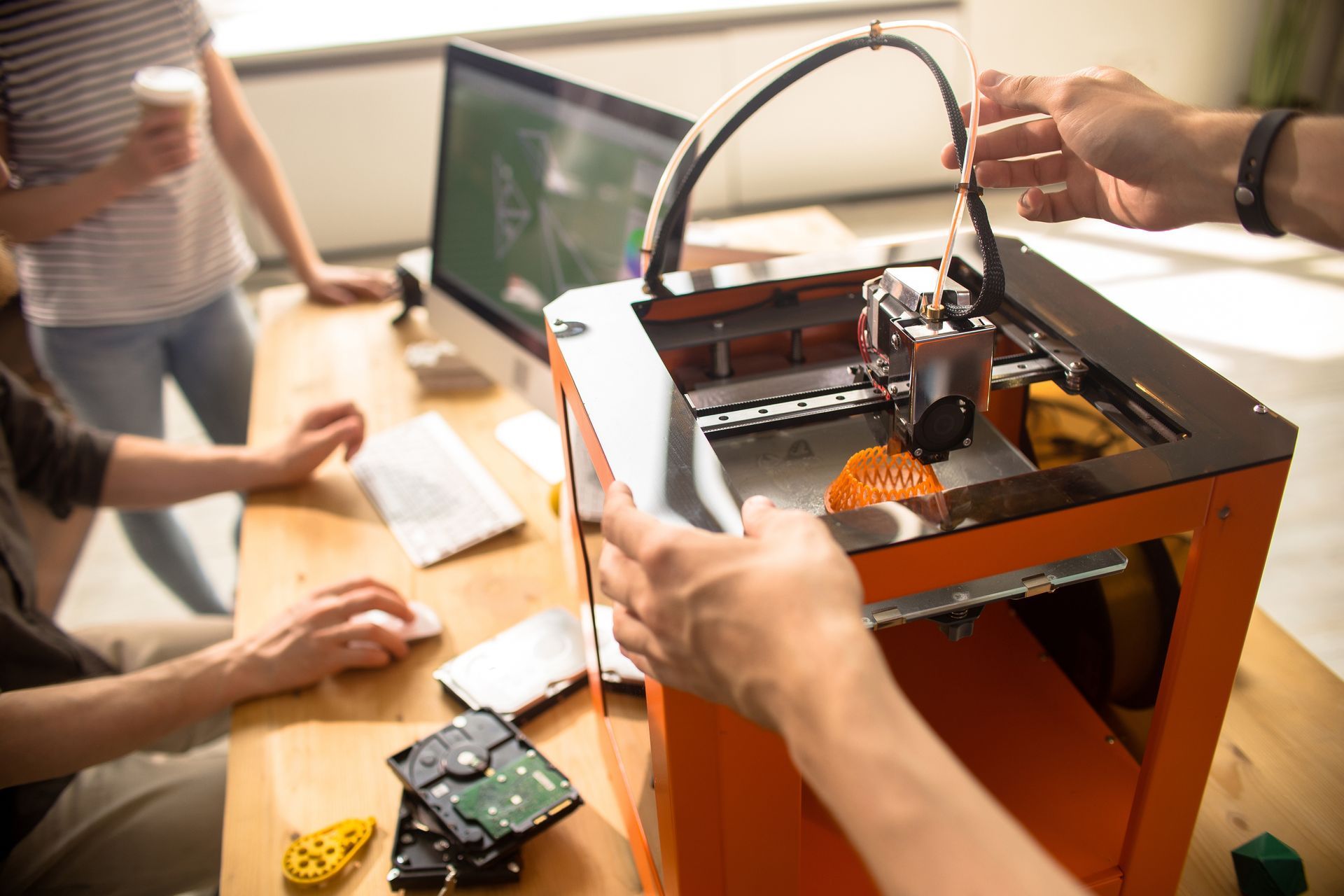

By3Design puts focus on making sure each 3D printing project matches what the client wants. They use custom solutions, giving people a lot of freedom to make their ideas real with the help of their team.

Here’s what helps their design process stand out from others:

- With advanced CAD services, they follow detailed specifications. This helps every product meet its needs.

- They offer material options such as ABS and Nylon for strength and use special SLA resins for smoother prints.

- They offer fast lead times for rapid prototyping and speed up production for clients.

- There are reliable post-processing choices to make sure the final product looks good.

- The team offers support for tricky shapes and fine detailing, so companies from aerospace or retail can get what they want.

Because they always provide quality customization in printing, By3Design has become a trusted partner for those wanting to make something new in Phoenix. They help many bring rapid prototyping and CAD services to life.

Future Possibilities And Advancements In 3D Printing Technology

Innovations in 3D printing are starting to change how industries work, helping businesses get better at rapid prototyping. With improvements in new processes like SLA and MJF, companies can make products that are more durable and meet all the right specifications. In Phoenix, more and more businesses are choosing these printing tools to make their design work faster. They use CAD systems in their workflows and combine them with 3D printing methods such as FDM. As the materials used for printing get better, there will be more ways to save money and make things more quickly. This growing mix of new tools and ideas will help people come up with customized solutions.

Conclusion

3D printing is pushing businesses in Phoenix toward new ideas and better ways to work. The technology is changing everything, from planes to health care. It brings the kind of choice and freedom to design that people cannot get with older ways of making things. By3Design leads this change, helping companies use 3D printing to improve what they do and what they give their customers. There are, for sure, a lot more great things to come in printing. If you want to see what 3D printing can do for your business in Phoenix,

contact us now!

By3Design Blog