From Concept to Reality: The Process of 3D Printing a Product

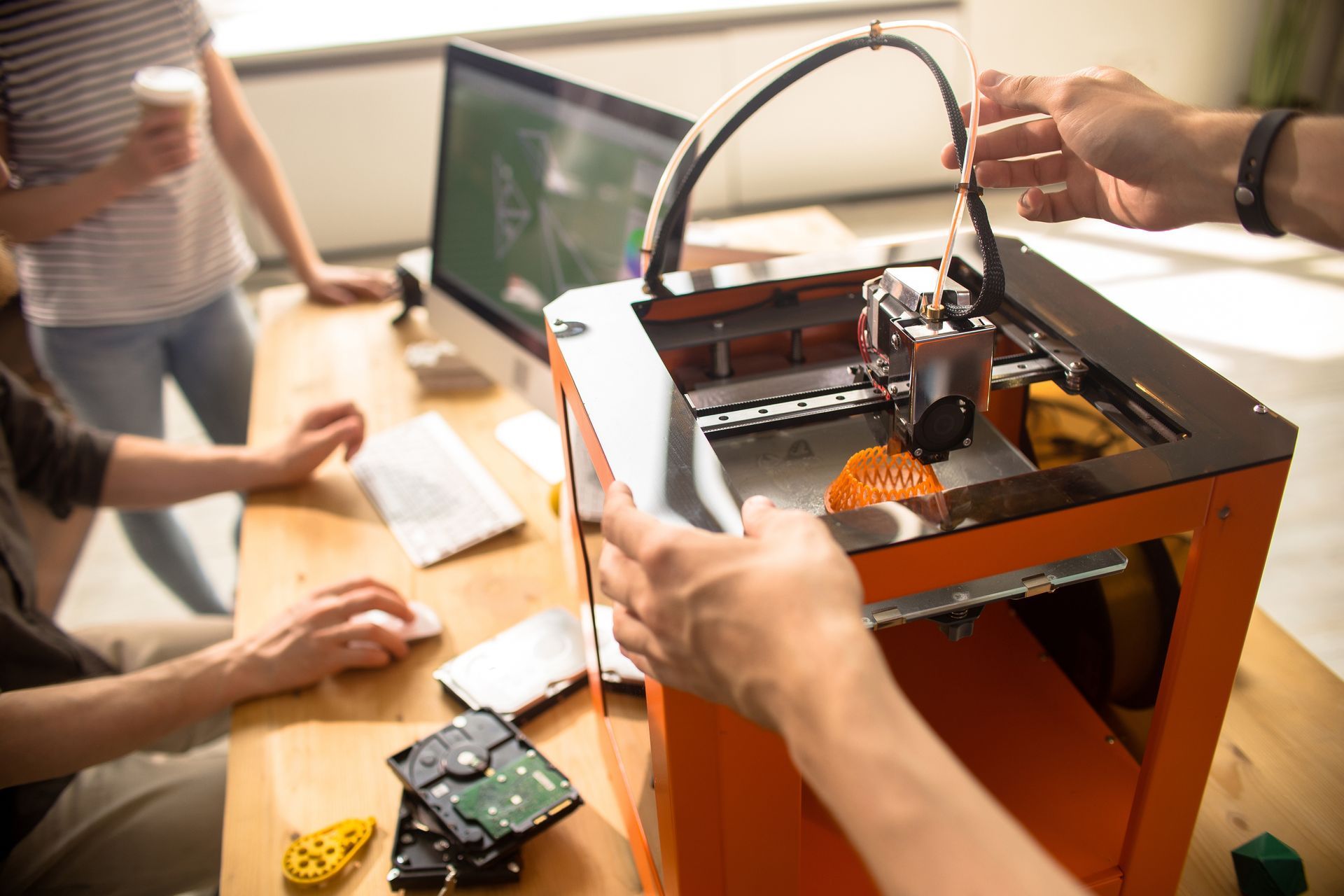

In today’s fast-paced world of innovation, 3D printing has become a revolutionary tool for transforming ideas into tangible products. For entrepreneurs and creators looking to bring their concepts to life, the ability to move from concept to reality has never been easier. The process involves various stages, from designing the model in 3D software to choosing the right materials and perfecting the final product. With 3D design consulting services, businesses and individuals can navigate the complexities of 3D printing with expert guidance to ensure the best results. This post will walk you through each essential step in the 3D printing process, helping you turn your ideas into finished products.

Designing a 3D Model Using CAD Software

The first and most crucial step in the 3D printing process is designing a model that can be printed. The most common tool for this is computer-aided design (CAD) software.

- Creating the Design: The product’s design starts with conceptual sketches that evolve into detailed digital blueprints. CAD software such as AutoCAD, SolidWorks, or Blender allows designers to create accurate 3D models with precise dimensions. These designs can be simple or complex, depending on the product requirements.

- Optimizing the Model for Printing: CAD software not only allows for the creation of the product but also lets the designer optimize it for printing. This includes ensuring that the design is structurally sound and printable with the chosen 3D printer.

- Collaboration with Design Experts: Utilizing 3D design consulting services can help refine the model to ensure it meets the technical specifications required for printing. Experts can provide advice on enhancing the design, minimizing material usage, and ensuring the product’s durability. Read “3D Design Consulting Services: By3Design Explained,” to learn how to have a smooth process with your 3D design and printing process.

- Design Validation: After completing the design, a virtual simulation or prototype can be tested within the CAD software to ensure it functions as intended before moving on to the actual printing process.

Preparing the Model for Printing (Slicing, File Formats)

Once the 3D model is ready, the next step is preparing it for printing. This process involves converting the 3D design into a file format compatible with 3D printers and slicing it into layers.

- Slicing the Model: The process of “slicing” refers to dividing the 3D model into horizontal layers. Printing across each layer is equivalent to one pass. Slicing software like Cura, PrusaSlicer, or Simplify3D generates these layers and outputs a G-code file that directs the 3D printer on how to print each layer precisely.

- Choosing the Right File Format: Common file formats for 3D printing include STL (Stereolithography) and OBJ. STL is the most widely used format because it provides a detailed representation of the 3D geometry, but depending on the printer and software, other formats like AMF or 3MF may be used.

- Adjusting Print Settings: The slicer software also allows users to adjust print settings such as layer height, infill density, and print speed. These settings are important for achieving the desired level of detail, strength, and speed during the printing process.

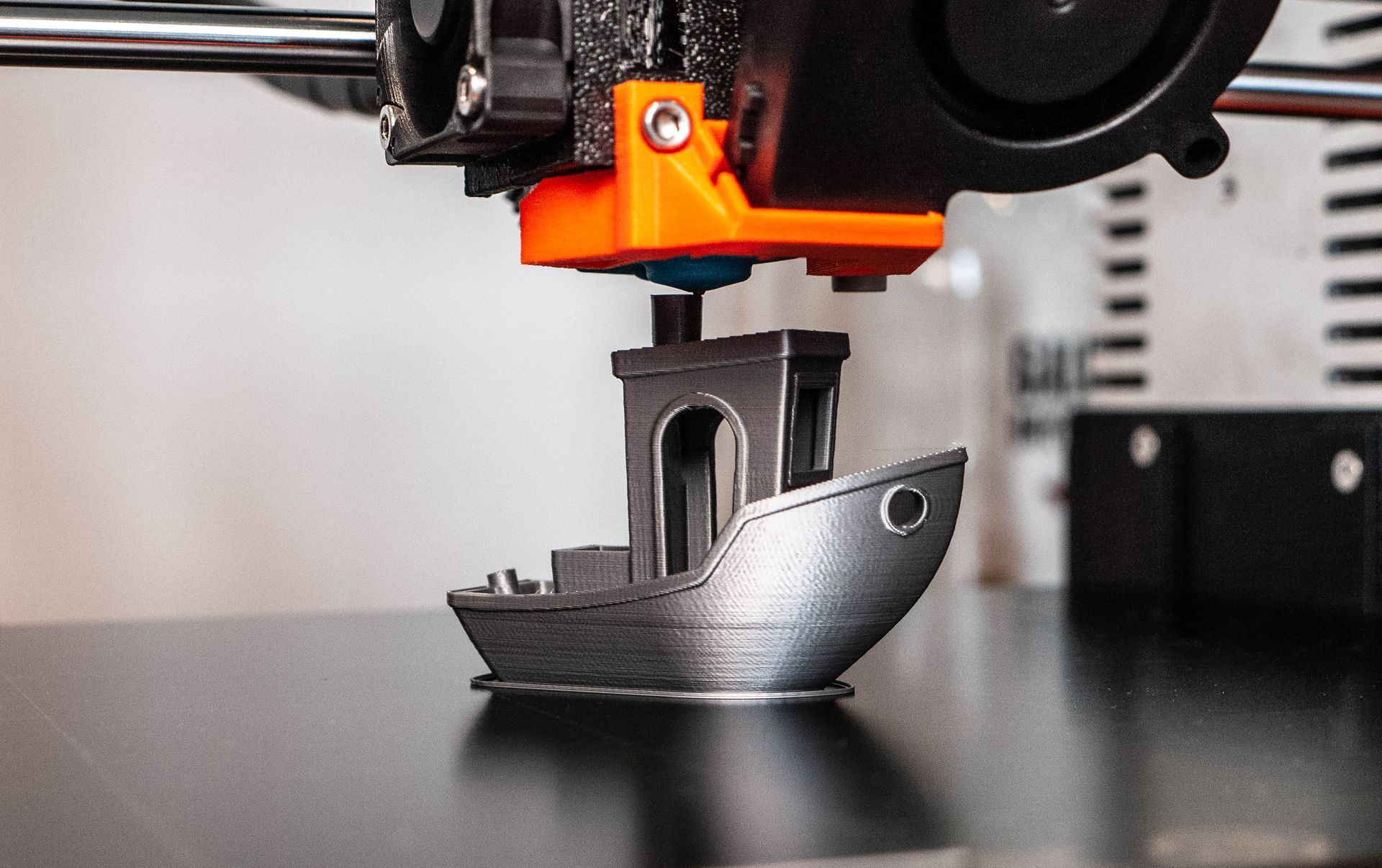

- Test Runs: Before printing the final product, some designers conduct a test print or use a virtual preview to ensure that the sliced model will print correctly and without errors.

Choosing the Right Material and Printer Settings

Selecting the right material is essential for ensuring that the final product meets functional, aesthetic, and durability requirements. Different materials and printer settings are suited to different types of prints.

1. Material Selection

Many 3D printing materials are available, however some of the more common ones include PETG, Acrylonitrile Butadiene Styrene (ABS), and Polylactic Acid (PLA). For functional prototypes or products, materials like ABS or nylon may be chosen for their strength and heat resistance, while PLA is typically used for aesthetic prototypes due to its ease of use.

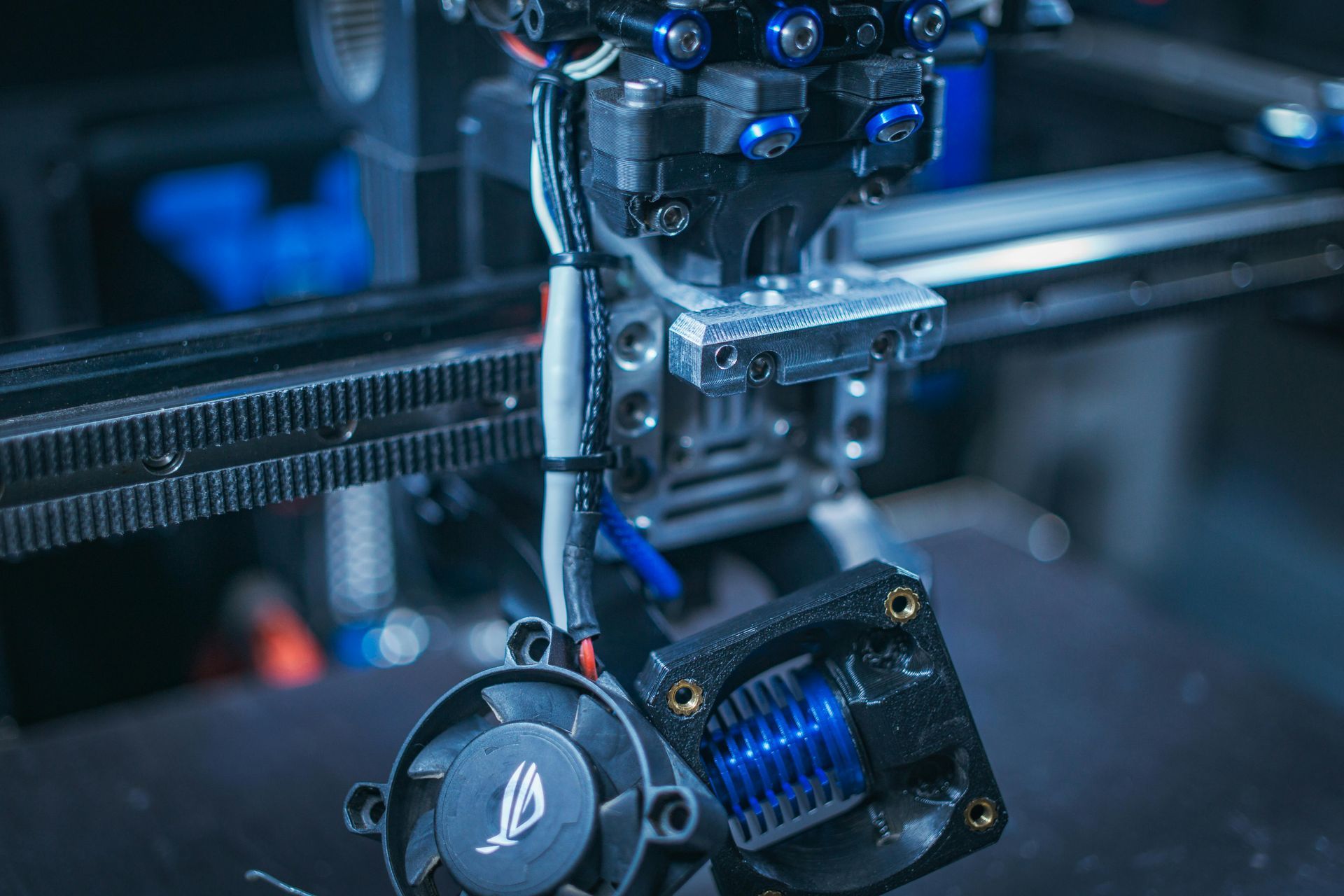

2. Printer Settings

Once the material is chosen, the printer settings must be adjusted. This includes setting the right temperature for both the extruder and heated bed, as well as choosing the appropriate print speed. These settings can affect the quality, strength, and appearance of the finished product.

3. Printer Type

There are different types of 3D printers available, including FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). Each type of printer uses a different method for creating the object and may require specific materials. Entrepreneurs must select the printer that aligns with their material and product needs.

4. Material Costs and Availability

Entrepreneurs also need to consider the cost and availability of materials. Certain materials may be more expensive or harder to source, making them less suitable for mass production or tight budgets.

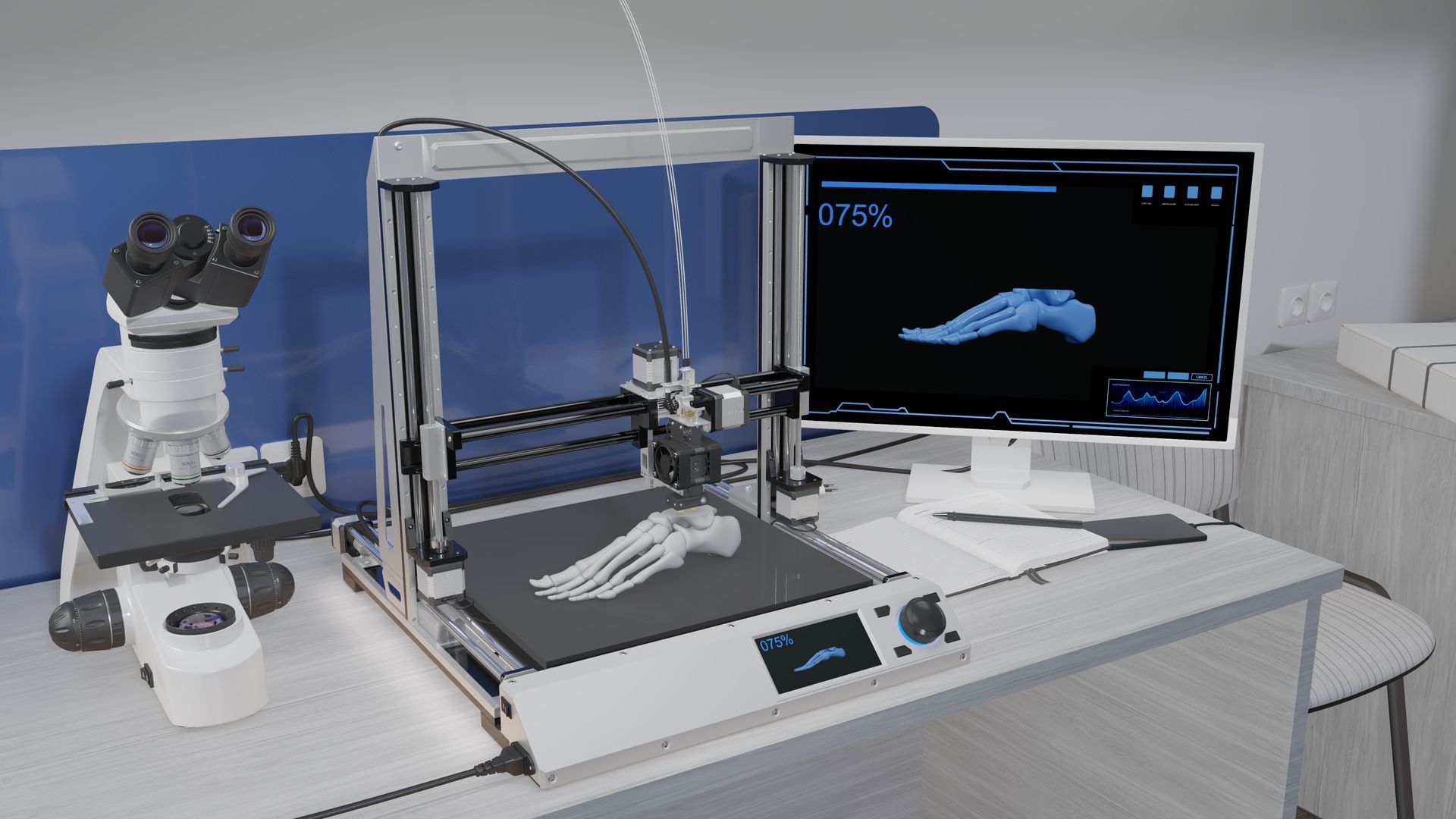

The Printing Process (Layer-by-Layer Creation)

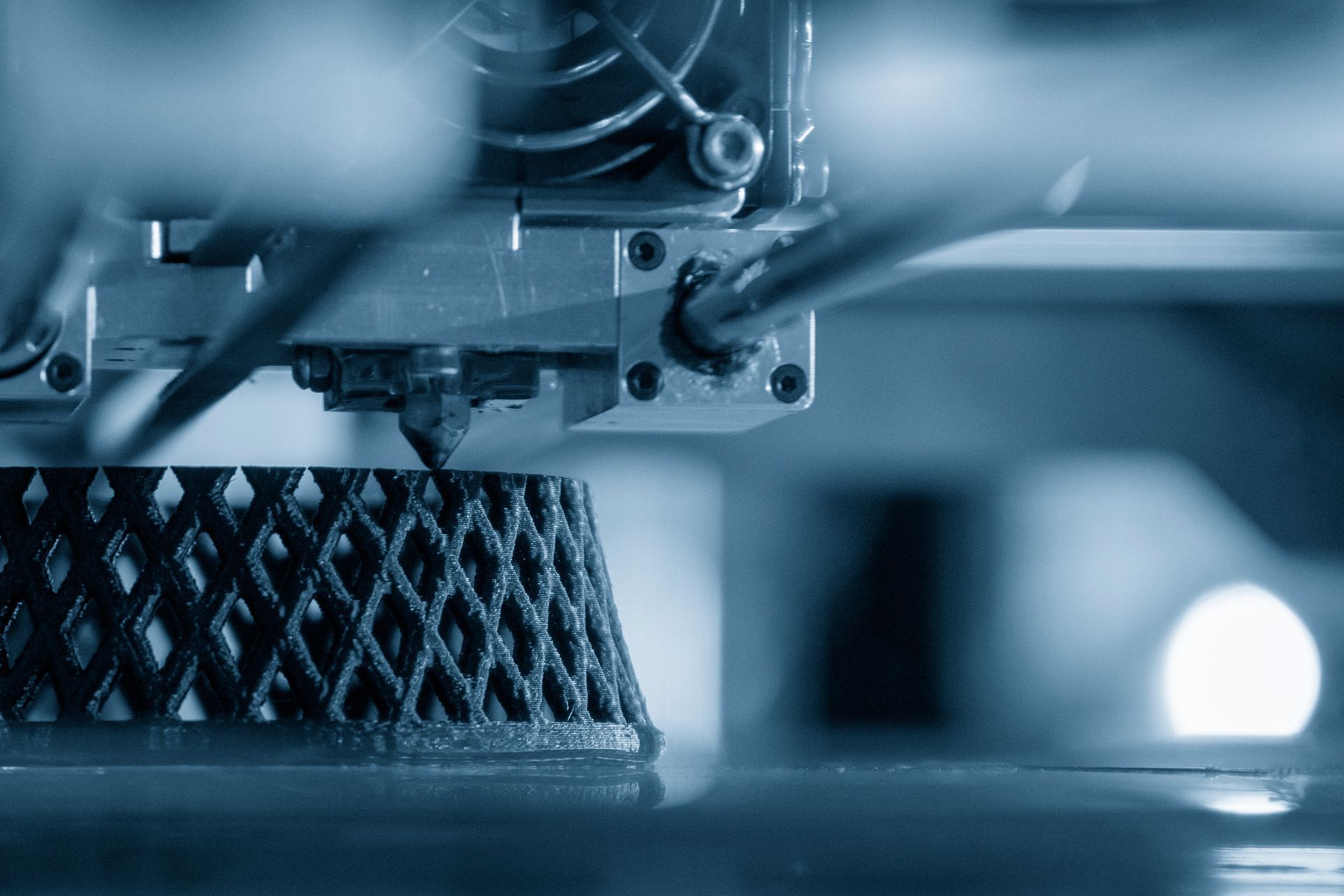

The actual 3D printing process is a fascinating journey of layer-by-layer creation.

- Layer-by-Layer Construction: 3D printing operates on the principle of additive manufacturing, where the material is added layer by layer to create the final product. Each layer bonds to the one below it as the printer nozzle extrudes melted material, solidifying as it cools.

- Build Plate Movement: The print starts at the base of the build plate and gradually moves upward, following the G-code instructions. As each layer is printed, the printer continues adding new material until the object is fully formed.

- Print Speed and Accuracy: Depending on the complexity of the model and printer settings, the print speed can vary. More intricate designs or higher-quality prints may take longer but offer more precise results. For faster prints, entrepreneurs can opt for a lower resolution, sacrificing detail for speed.

- Monitoring the Process: Many printers are equipped with features that allow users to monitor the print in real time. Monitoring ensures that the printing process is running smoothly, with no issues like warping, clogging, or misprints.

Post-Processing: Cleaning, Assembling, Finishing

Once the 3D print is complete, the final product often requires post-processing to remove excess material, refine the finish, and assemble components.

- Cleaning the Print: After printing, the object typically requires cleaning to remove any excess support material, dust, or residue. For FDM prints, support structures may need to be manually removed, while SLA prints often require washing in isopropyl alcohol to remove uncured resin.

- Assembly: If the print is made up of multiple parts, assembly is required. This may involve gluing, screwing, or snapping pieces together. Depending on the design, assembly can be simple or complex.

- Finishing Touches: The final step in post-processing often includes sanding, painting, or polishing the printed product to enhance its appearance and functionality. Some entrepreneurs may also apply coatings for additional strength, texture, or finish.

- Quality Assurance: Entrepreneurs should always perform quality checks after post-processing to ensure that the final product meets the necessary standards for both function and aesthetics.

Conclusion

3D printing is a transformative technology that allows entrepreneurs to take their ideas from concept to reality with remarkable efficiency. Through careful design, material selection, and printing techniques, creators can prototype, test, and produce innovative products. Whether you're a seasoned entrepreneur or just starting, understanding each step in the process of 3D printing is essential for achieving success. With the right tools and expertise, such as 3D design consulting services, entrepreneurs can unlock new possibilities and stay ahead of the curve in today's competitive market.

If you're ready to turn your concept into a tangible product,

By3Design can guide you through the entire 3D printing process. From initial design consultation to final product refinement, our team offers expert insights to help you succeed. We specialize in creating high-quality prototypes and finished products, tailored to your specific needs. Let us handle the technical details so you can focus on what matters most—bringing your vision to life.

Get in touch with us today to start your 3D printing journey.

By3Design Blog