The Growing Demand For 3D Printing In The Tech Industry

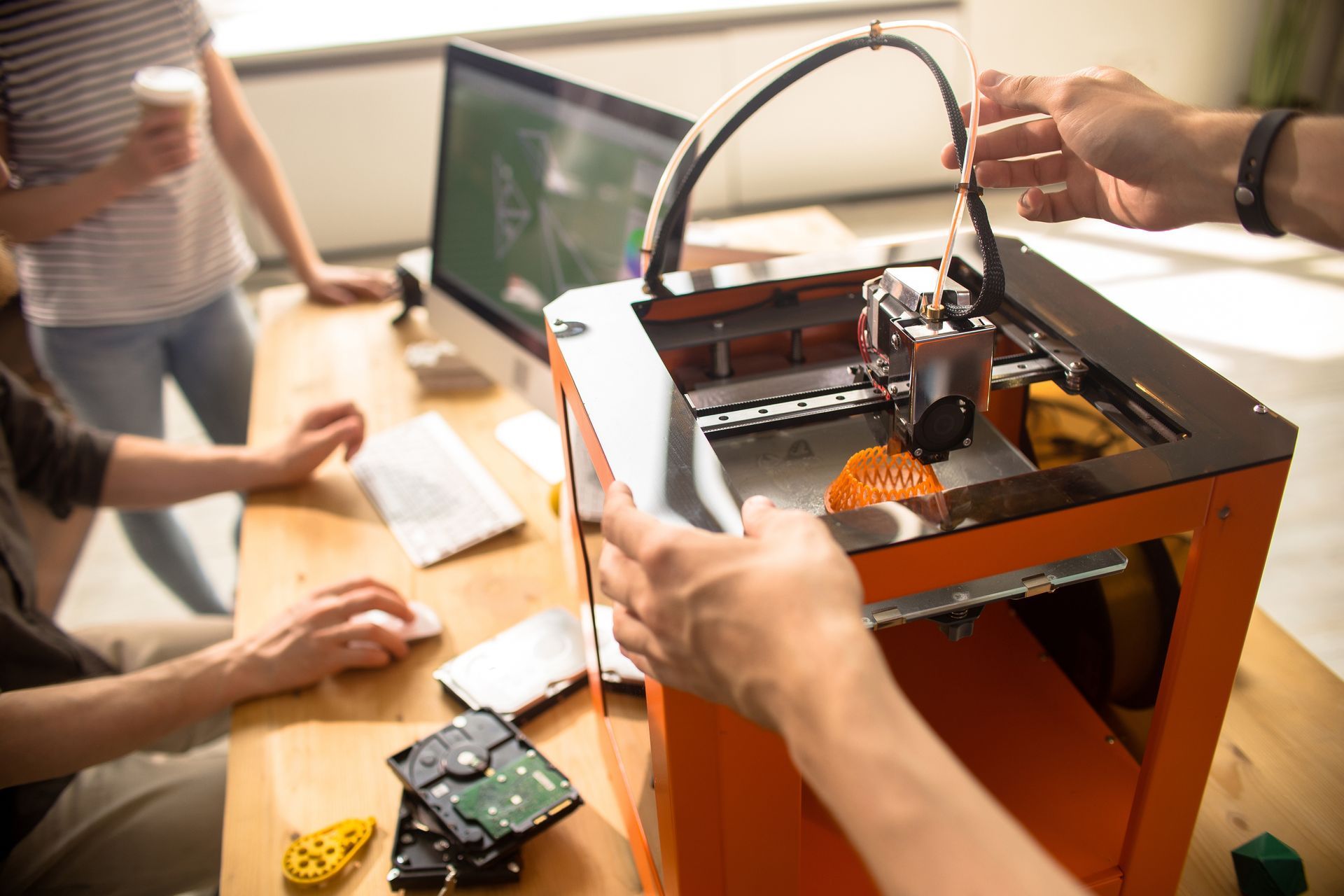

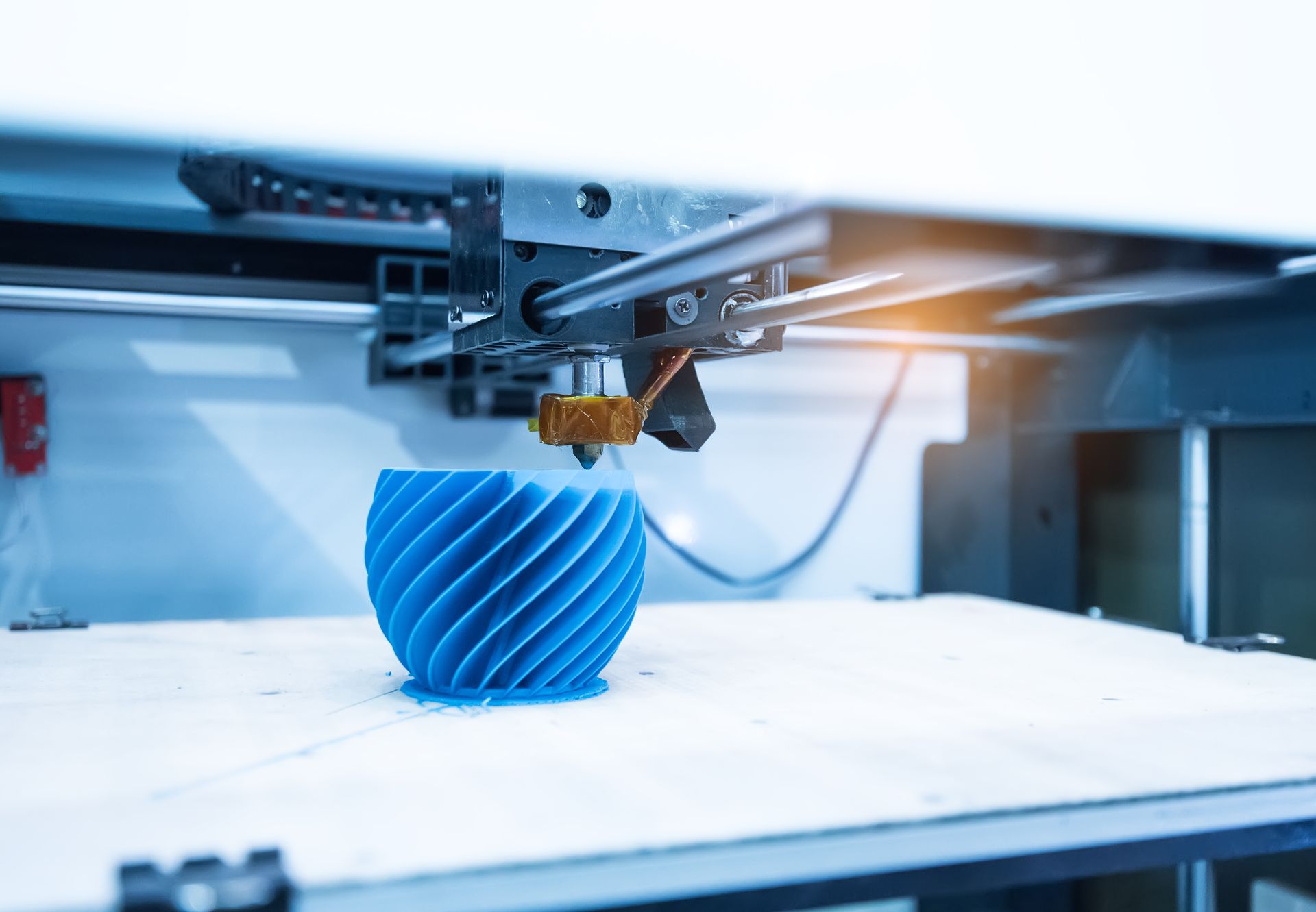

3D printing is changing the tech industry very quickly. In Phoenix, Arizona, companies like By3Design use advanced printers to create designs on time. They work with CAD files or STL formats. This new way of making things makes sure quality prototypes and production runs are done in just a few business days. As the need for accurate and scalable solutions grows, 3D printing is now a key part of how tech companies in Phoenix achieve their project goals.

Overview Of 3D Printing Technologies Used In The Tech Industry

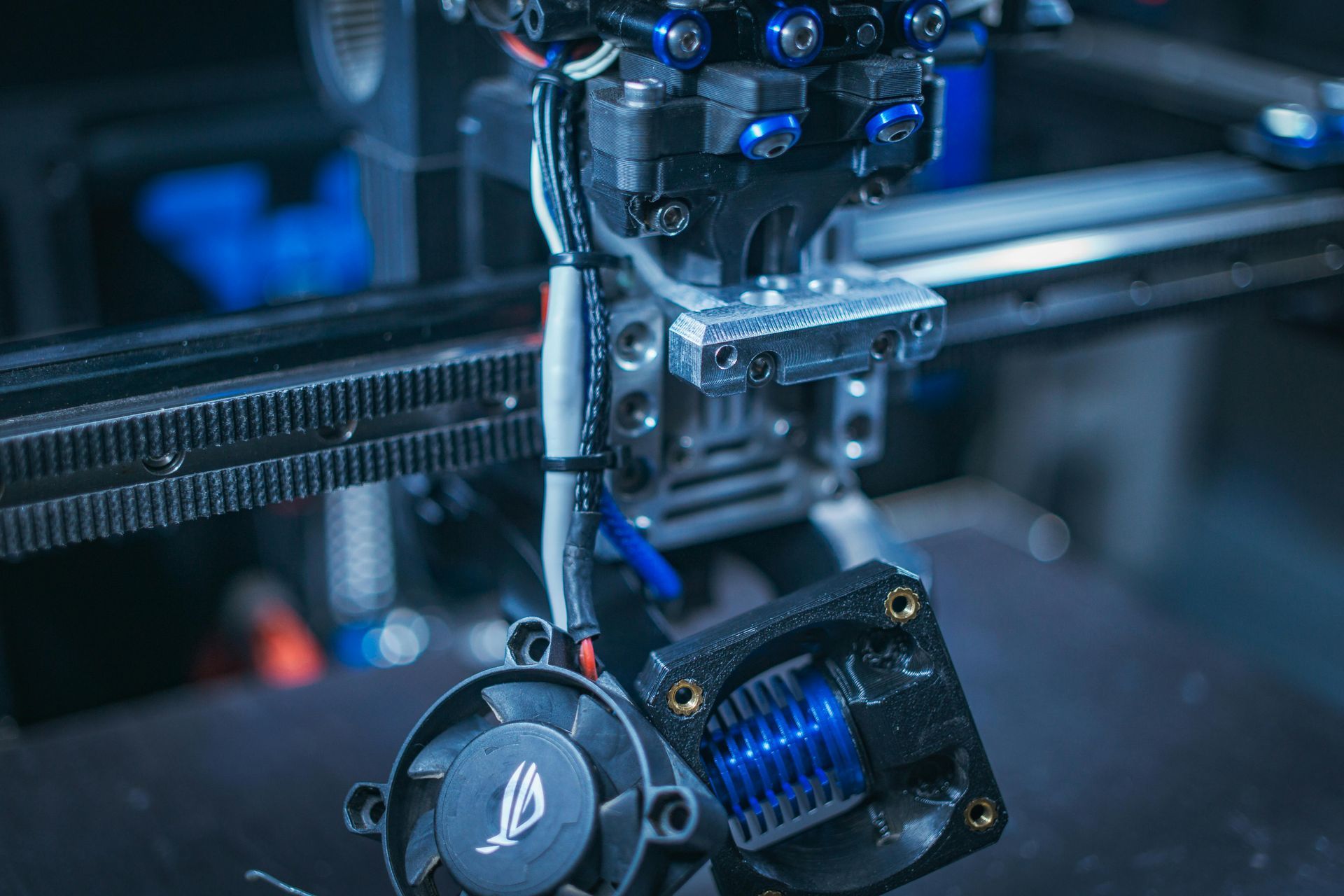

The tech industry is changing because of advanced 3D printing AZ technologies. Methods like Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS) allow engineers to create detailed designs faster. They help bring products to market sooner. These techniques are great for making electronic parts and other useful products. They combine speed, precision, and cost savings.

Companies in fields like aerospace, automotive, and medical devices gain a lot from these printing technologies. For example, SLA printers make beautiful prototypes with high resolution. SLS printers create strong parts using nylon. FDM and DMLS are becoming popular because they handle the growing complexity of tech designs. These technologies help businesses find new ways to solve production problems.

The Significance of FDM, SLA, SLS, And DMLS In Modern Manufacturing

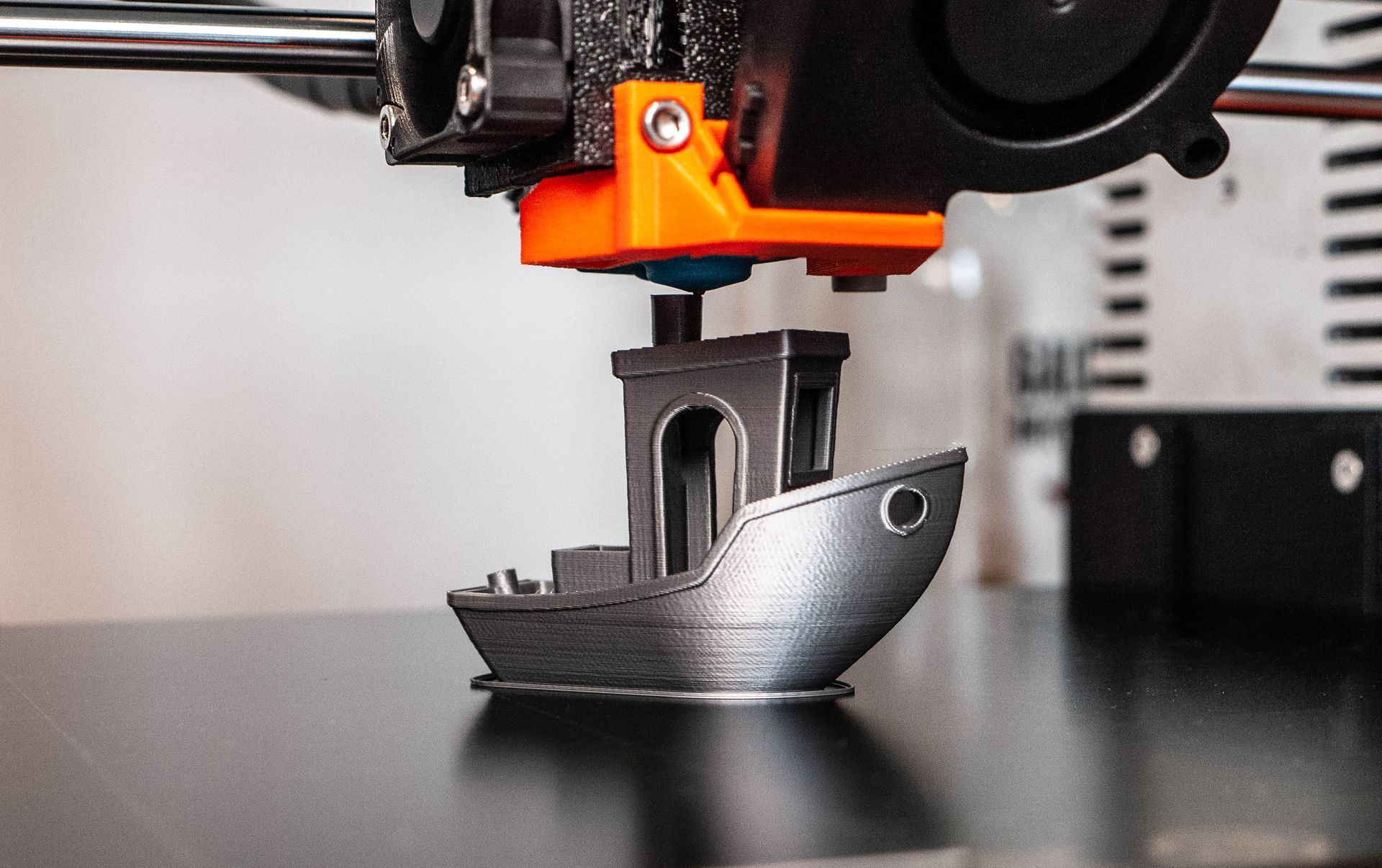

FDM printing is known for being cost-effective and flexible for making prototypes. It uses thermoplastic polymers to create functional parts layer by layer. FDM printers can handle both simple designs and complex shapes needed in fields like defense or medical technology. The materials used, like nylon and PLA, provide the strength needed for tough tasks.

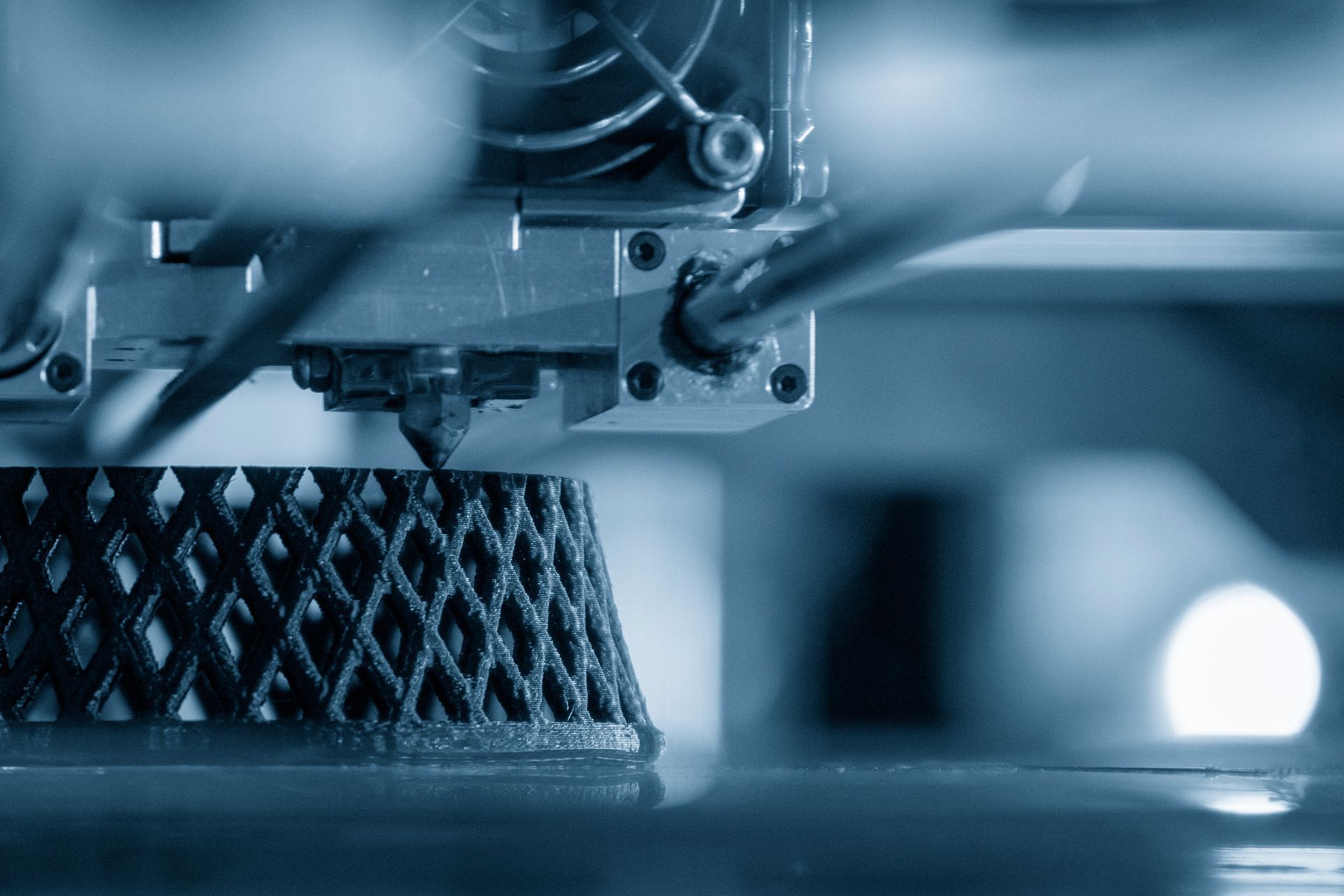

In contrast, SLA 3D printing aims to create high-resolution prototypes. It uses photopolymer resins that give smooth surfaces, great for presentation models or early concept designs. Some special resins can make SLA useful for flexible or castable parts.

For industries that need parts that work well, SLS and DMLS are very important. SLS uses powder fusion to make strong, engineering-grade parts, mostly from nylon, within three business days. On the other hand, DMLS is for businesses that need metal parts for aerospace or automotive uses. It offers high precision and great utility for these industries.

Advancements And Innovations In 3D Printing For Electronics And Gadgets

Advanced 3D printing technologies are making big changes in how electronics are made. The CAD and STL capabilities let us model detailed devices accurately. SolidWorks software helps by allowing the design of complex models for electronic gadgets.

A major breakthrough is the creation of high-resolution housings for components using SLA printers. These printers can create detailed prints, which is important for the smart designs needed in portable electronics and wearables.

- CAD integration makes it easier to improve part designs, helping them work with different materials.

- STL files help simplify the digital shaping of electronic cases and connectors.

- High-resolution printing ensures compact designs have great looks and performance.

- Multi Jet Fusion technology gives sturdy mechanical properties, which is important for the strength of gadgets.

With these advancements, electronics makers can improve product strength and speed up the production of technology-focused items.

Key Benefits Of Implementing 3D Printing In Tech Production

Integrating 3D printing technology into tech production brings many benefits. Companies see significant cost reductions during the development stage by using additive manufacturing instead of traditional methods. Now, they can create more complex designs that weren't possible before, and they don't lose efficiency.

Businesses also enjoy faster turnaround times. With processes like SLA and SLS, prototypes can be ready in just a few business days. This reduces project delays while keeping precision high. This change encourages innovation in tech companies, helping them succeed in competitive markets.

Cost Reduction And Increased Efficiency In Prototyping

One big reason the tech industry likes 3D printing is that it can cut costs. Traditional ways often need a lot of resources for molds or tools, which makes prices go up. FDM and SLA printing fix this by using materials wisely for prototypes.

Another benefit is how efficient production can be. SLA printers can create high-resolution prototypes in just two business days. This speeds up designing and testing, so tech companies can save important resources and spend more on new ideas.

Using CAD/STL tools with DMLS or SLS technologies makes prototyping simple. Companies can test many design versions for electronic parts or adapters quickly without having to wait. This smooth process helps bring ideas to market faster while keeping high quality.

Customization And Complexity In Design Made Easy

3D printing has changed the game for tech companies that want special, customized solutions. They use CAD software to change designs quickly, meeting unique needs like flexible accessory gadgets or specific sizes of products.

Now, design complexity is not a problem. SLA printers offer detailed prototypes, letting engineers try out new product features. On the other hand, SLS printers use nylon parts, making them great for devices that do multiple jobs.

Being able to create detailed designs leads to more accessibility and creative ideas. For example, car companies use MJF printers to make complex tools and parts. This helps them save time while meeting exact project needs, and they do it with ease.

How By3Design Is Revolutionizing 3D Printing For Tech Companies

By3Design is changing how tech companies think about additive manufacturing. Their smart approach focuses on helping customers. This means that every prototype or production run is made to fit exact needs without delays.

Located in Phoenix, AZ, By3Design uses selective laser sintering (SLS) technology along with handy SolidWorks CAD tools to create strong nylon products. Their new solutions help tech businesses get past design issues and boost production in a smooth way. Learn more on Rapid Prototype 3D Printing: Latest Innovations.

The Future Of 3D Printing In The Tech Industry

The future of 3D printing in the tech world is very exciting. New materials, like nylon, and better techniques for SLA and SLS are opening up many new possibilities.

With 3D printing technologies, companies can now offer more customized products and scale up production easily. This makes manufacturing faster and helps them create new and improved gadgets, especially for consumers and IoT devices.

In Phoenix, companies like By3Design are leading the way. They focus on CAD modeling and improving printers. This work helps the tech industry keep up with what consumers want: faster and better products.

By3Design's Unique Approach To 3D Printing

By3Design has a special way of doing things. They focus on understanding what clients want by using a detailed scan-and-engineer method. They use the best techniques in the industry for accuracy and growth.

| Technology Used | Benefits Provided |

|---|---|

| SLS Printing | Great for strong, complex nylon designs |

| SLA Printing | Allows for high-quality visual prototypes |

| Multi Jet Fusion (MJF) | Helps with industrial-level production |

| CAD Integration | Makes design changes easier |

They stand out because they promise to provide high-quality results quickly. By3Design helps tech companies adjust to market needs using trustworthy 3D printing systems.

By3Design's Approach To 3D Printing For The Tech Industry

By3Design is changing the tech industry with its advanced 3D printing tools. They use SLA and SLS printers to make parts that fit complex project needs accurately.

Their use of CAD modeling helps clients in Arizona get custom designs for production. By3Design makes products using nylon, serving industries like electronics and aerospace. They help remove design challenges for real-world uses.

What makes their method special is its scalability. Whether it's high-detail prototypes or working parts, By3Design can easily change to meet business goals. They work quickly to support Phoenix’s fast-growing tech world.

Conclusion

As we explore the rising need for 3D printing in the tech field, we see how this new technology changes how businesses create products. It makes prototyping faster and allows for better customization. The benefits of 3D printing cannot be ignored. By3Design leads this change by providing special solutions for tech companies. As the industry grows, it is important to keep up with new advancements and use these technologies for success. Don't miss the chance to benefit from 3D printing.

Contact us today to find out how we can help you improve your production work.

By3Design Blog