Mastering Slicing Software: 3D Printing Basics

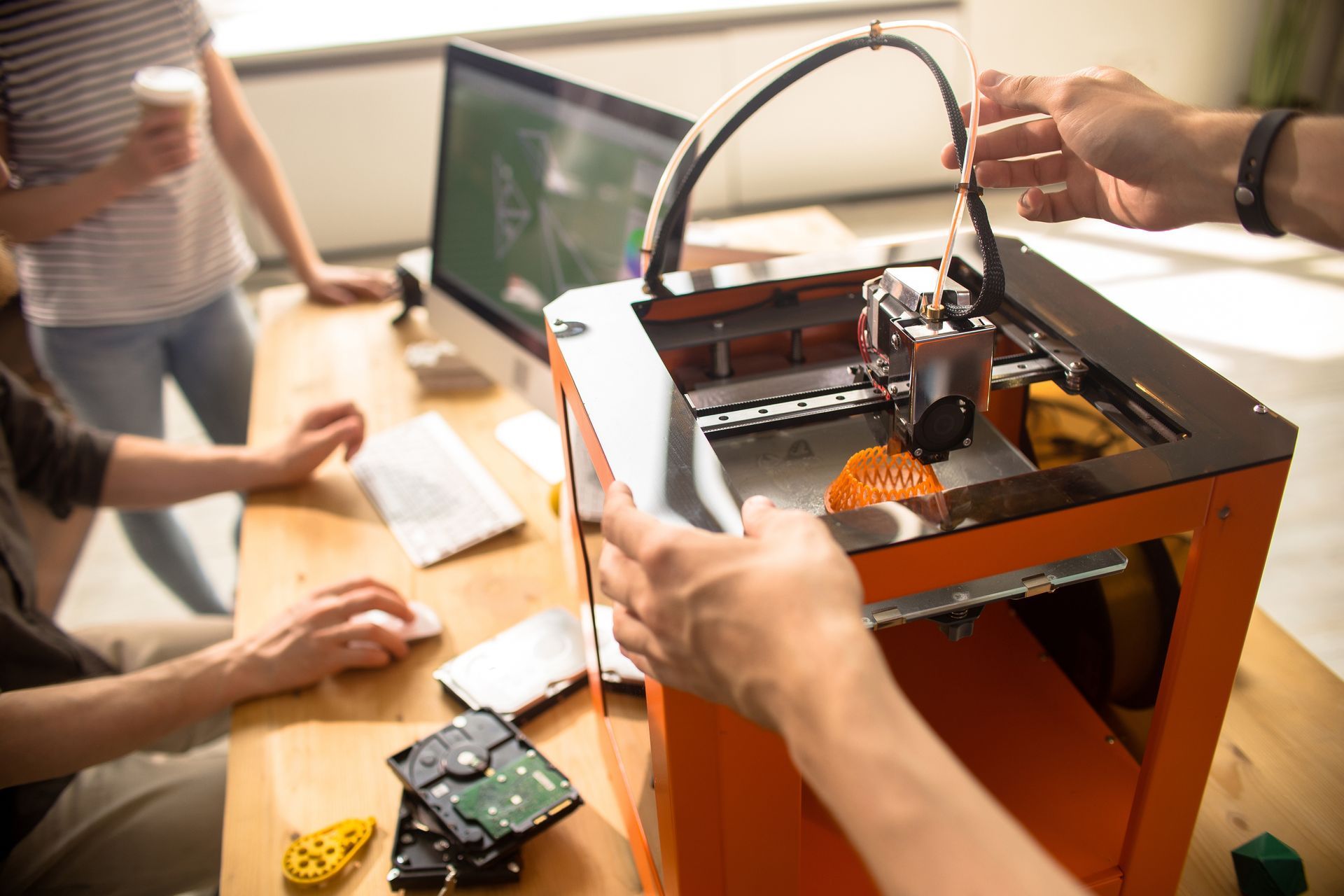

In the world of 3D printing, slicing software is the bridge between your creative vision and the tangible model produced by your 3D printer. For enthusiasts and professionals in Phoenix, AZ, By3Design is a trusted resource for mastering slicing software like Cura, PrusaSlicer, and other cutting-edge tools. Whether you’re new to 3D printing or a seasoned maker, understanding the nuances of slicing software is key to achieving high-quality prints, and By3Design is here to guide you.

What Is Slicing Software?

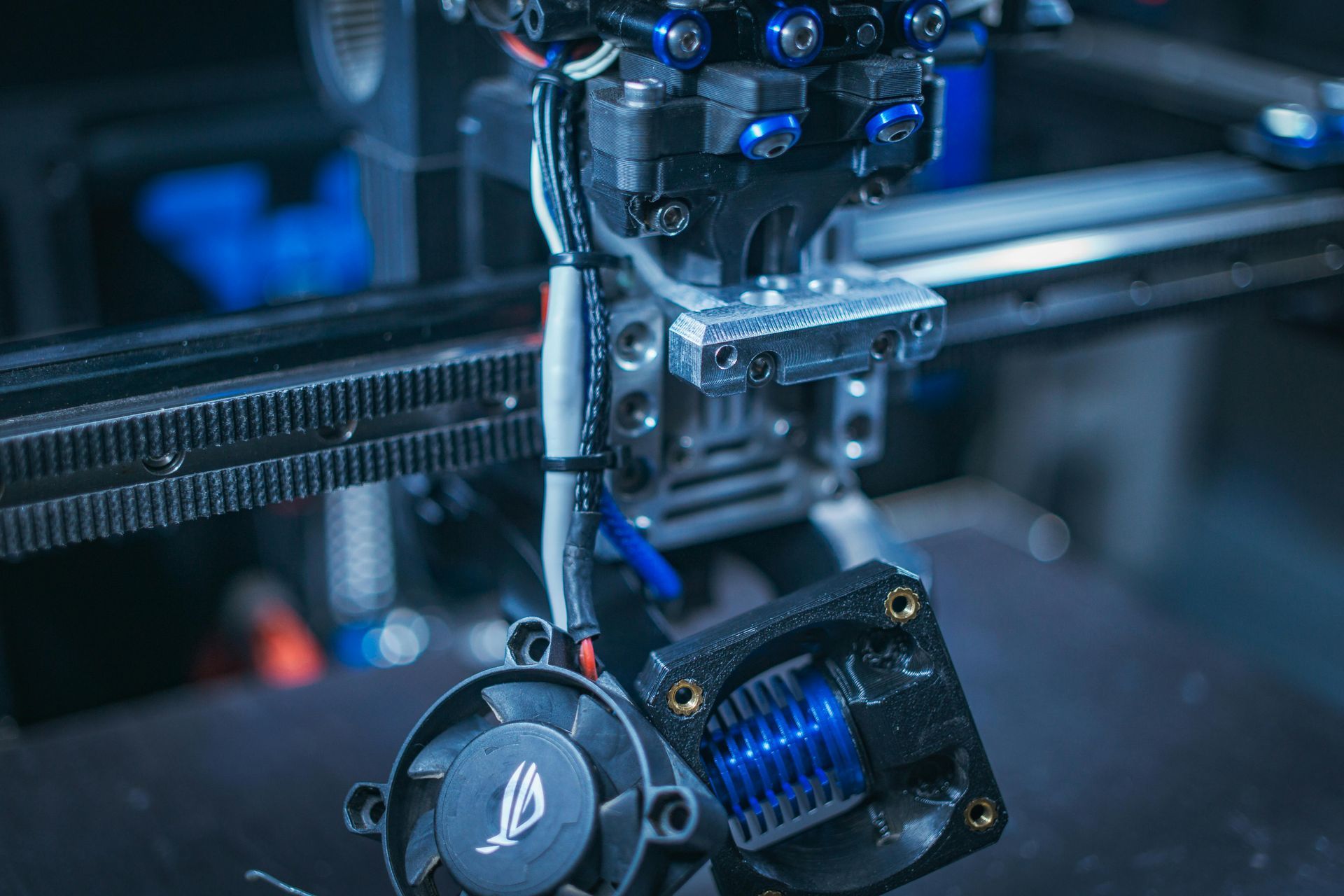

Slicing software is a crucial tool in 3D printing. It translates your 3D model file, typically in STL, OBJ, or 3MF format, into a series of instructions that your printer can execute. These instructions, known as G-code, dictate the movement of the printer’s nozzle, bed, and other components. Selecting the right slicer and optimizing its settings can significantly impact the quality, strength, and appearance of your prints.

Why Master Slicing Software?

For anyone engaging with 3D printing Phoenix AZ the ability to optimize slicing software is as important as having a reliable printer. Mastering slicing software offers the following benefits:

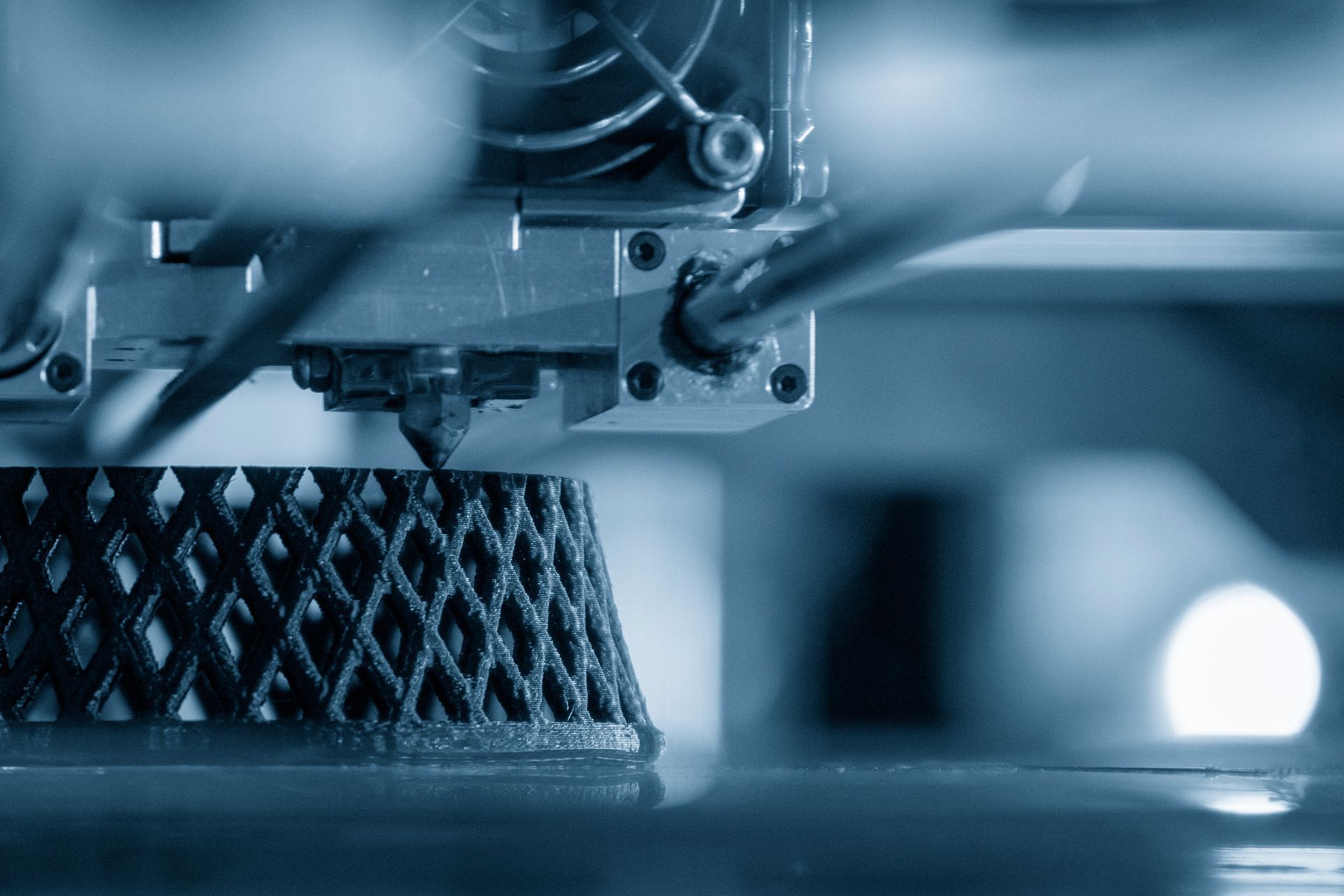

- Improved Print Quality: Fine-tuning parameters like layer height, print speed, and infill density ensures smoother finishes and detailed results.

- Time Efficiency: By adjusting settings like layer height and infill, you can optimize print times without compromising quality.

- Material Savings: Properly configured slicing settings minimize wasted filament, making your projects more cost-effective.

- Problem Prevention: Understanding advanced settings allows you to troubleshoot issues like stringing, warping, and layer adhesion.

At By3Design, we emphasize the importance of mastering slicing software to get the most out of your 3D printer. Let’s dive into two popular slicers: Cura and PrusaSlicer, along with a quick overview of other notable options.

Cura: A Versatile Slicing Powerhouse

Cura, developed by Ultimaker, is one of the most widely used slicing software tools globally. Its user-friendly interface and robust features make it a favorite among hobbyists and professionals.

Key Features Of Cura

- Customizable Profiles: Cura comes with pre-configured profiles for various printers and materials, which can be further fine-tuned.

- Extensive Plugins: Expand the functionality of Cura with plugins for things like octoprint integration, CAD model repair, and more.

- Adaptive Layers: This feature adjusts layer height dynamically for curved surfaces, improving detail while reducing print time.

- Support Customization: Cura’s tree supports are particularly useful for minimizing filament waste and improving support removal.

Tips For Using Cura

- Start with Recommended Profiles: For beginners, Cura’s built-in profiles are a great starting point. As you gain experience, you can modify settings to suit specific needs.

- Leverage Preview Mode: Use the preview feature to visualize each layer and identify potential issues before printing.

- Experiment with Experimental Features: Cura offers advanced settings like ironing (for smoothing top layers) and coasting (to reduce stringing).

By3Design hosts workshops in Phoenix, AZ, to help you navigate Cura’s extensive features, ensuring you get the most out of this powerful software.

PrusaSlicer: Tailored For Precision

PrusaSlicer, originally designed for Prusa 3D printers, has grown into a feature-rich slicer compatible with a wide range of printers. Its focus on precision and adaptability makes it a top choice for intricate projects.

Key Features Of PrusaSlicer

- Multi-Material Printing: PrusaSlicer’s advanced settings for multi-material printing allow for complex designs with different filaments.

- Custom Supports: Unlike many slicers, PrusaSlicer lets you add or remove supports manually for greater control.

- Advanced Filament Profiles: Optimized profiles for Prusa printers and popular filaments ensure high-quality prints with minimal tweaking.

- Variable Layer Heights: This feature allows you to adjust layer height in specific regions, balancing detail and print time.

Tips For Using PrusaSlicer

- Use the Expert Mode: While beginner and advanced modes are great starting points, expert mode unlocks the full potential of PrusaSlicer.

- Take Advantage of Custom Supports: Place supports only where needed to save material and simplify post-processing.

- Optimize Cooling Settings: Fine-tune cooling parameters for improved overhangs and bridges.

By3Design offers tailored tutorials for PrusaSlicer users in Phoenix, AZ, helping you harness its full capabilities and elevate your 3D printing projects.

Beyond Cura And PrusaSlicer: Exploring Other Options

While Cura and PrusaSlicer dominate the 3D printing landscape, other slicing software tools may better suit specific needs:

- Simplify3D: Known for its advanced control and print simulation, Simplify3D is popular among professionals. Its robust settings make it ideal for complex projects.

- IdeaMaker: Developed by Raise3D, IdeaMaker features an intuitive interface and is particularly well-suited for Raise3D printers.

- Slic3r: As the foundation of PrusaSlicer, Slic3r remains a reliable open-source option with a strong community following.

At By3Design, we encourage makers in Phoenix, AZ, to explore different slicers to find the one that aligns with their workflow and project requirements.

Mastering Slicing With By3Design

By3Design is your go-to destination for 3D printing in Phoenix, AZ. We offer comprehensive support, from printer setup to advanced slicing tutorials. Here’s how we can help: Explore When Should You Work with Professional 3D Printers? for more information.

- Workshops and Training: Our hands-on sessions cover everything from slicing basics to advanced techniques, tailored to your skill level and goals.

- Printer-Specific Guidance: Whether you use an Ender, Prusa, or Ultimaker printer, we provide guidance on optimizing slicer settings for your hardware.

- Material Expertise: Learn how to adjust slicer settings for PLA, PETG, ABS, and specialty filaments like TPU or carbon fiber composites.

- Troubleshooting Assistance: Stuck on a tricky print? Our team can help diagnose and resolve slicing-related issues to get you back on track.

Conclusion

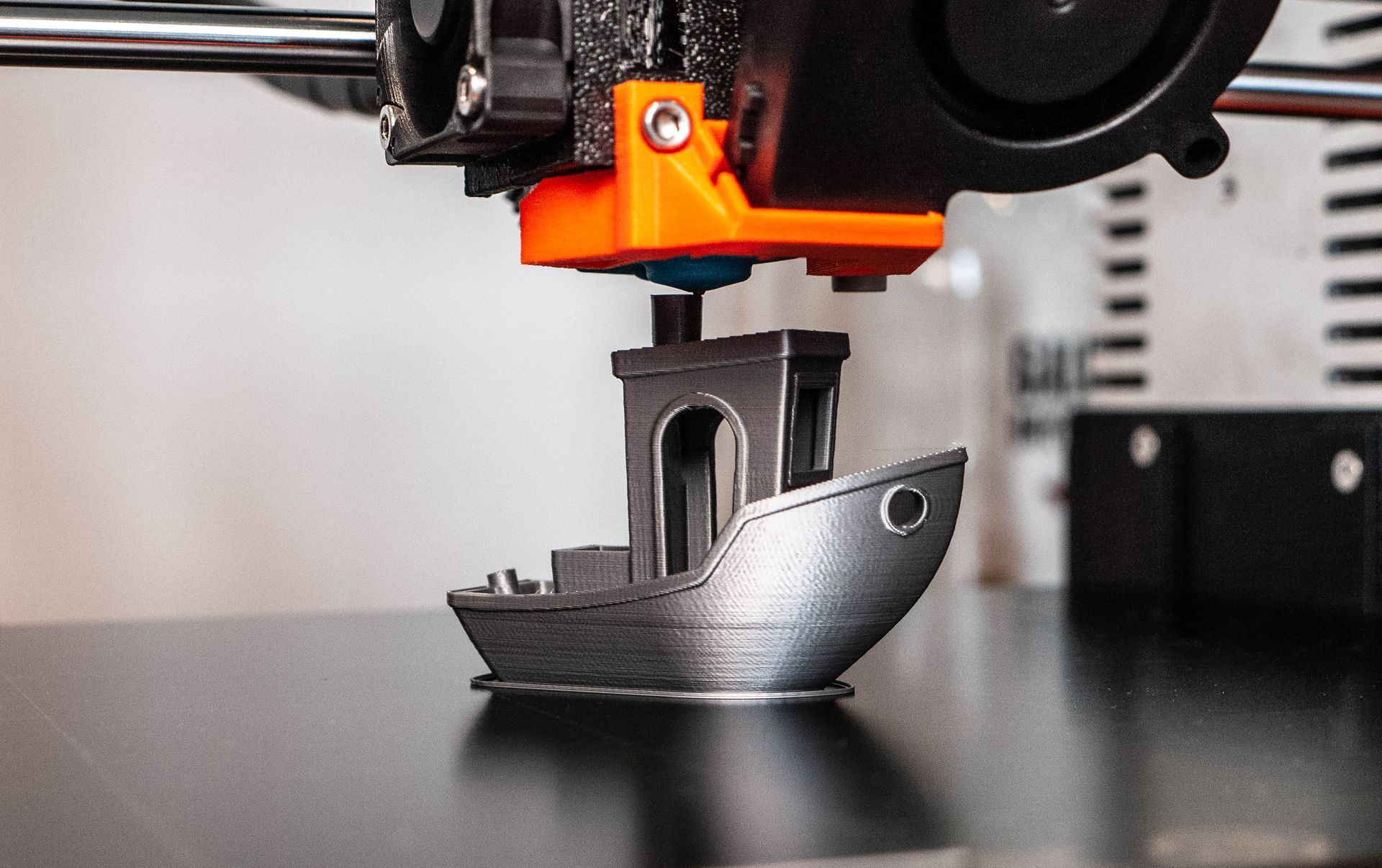

Mastering slicing software like Cura, PrusaSlicer, and others is essential for anyone involved in 3D printing. For makers in Phoenix, AZ, By3Design provides the expertise and resources needed to elevate your 3D printing projects. Whether you’re creating prototypes, artistic models, or functional parts, understanding and optimizing slicer settings will help you achieve superior results.

Ready to unlock the full potential of your 3D printer?

Visit By3Design in Phoenix, AZ, for hands-on workshops, expert advice, and all the tools you need to master slicing software and beyond.

By3Design Blog