3D Design Consulting In The Medical Device Industry

In the fast-paced world of medical innovation, the ability to rapidly develop, prototype, and refine products can mean the difference between life-saving advancements and stagnation. The medical device industry, a cornerstone of modern healthcare, thrives on precision, innovation, and compliance with stringent regulatory standards. This is where 3D design consulting emerges as a transformative force, and By3Design is leading the charge, offering unparalleled expertise tailored specifically to this critical sector.

The Role Of 3D Design Consulting In Medical Devices

3D design consulting has redefined the way medical devices are conceptualized, developed, and brought to market. It provides a seamless integration of advanced design tools and expert guidance, enabling companies to optimize product functionality, enhance usability, and maintain compliance with industry regulations. By3Design’s 3D design consulting services play a pivotal role in empowering medical device manufacturers to stay ahead of the curve, offering bespoke solutions that address unique challenges.

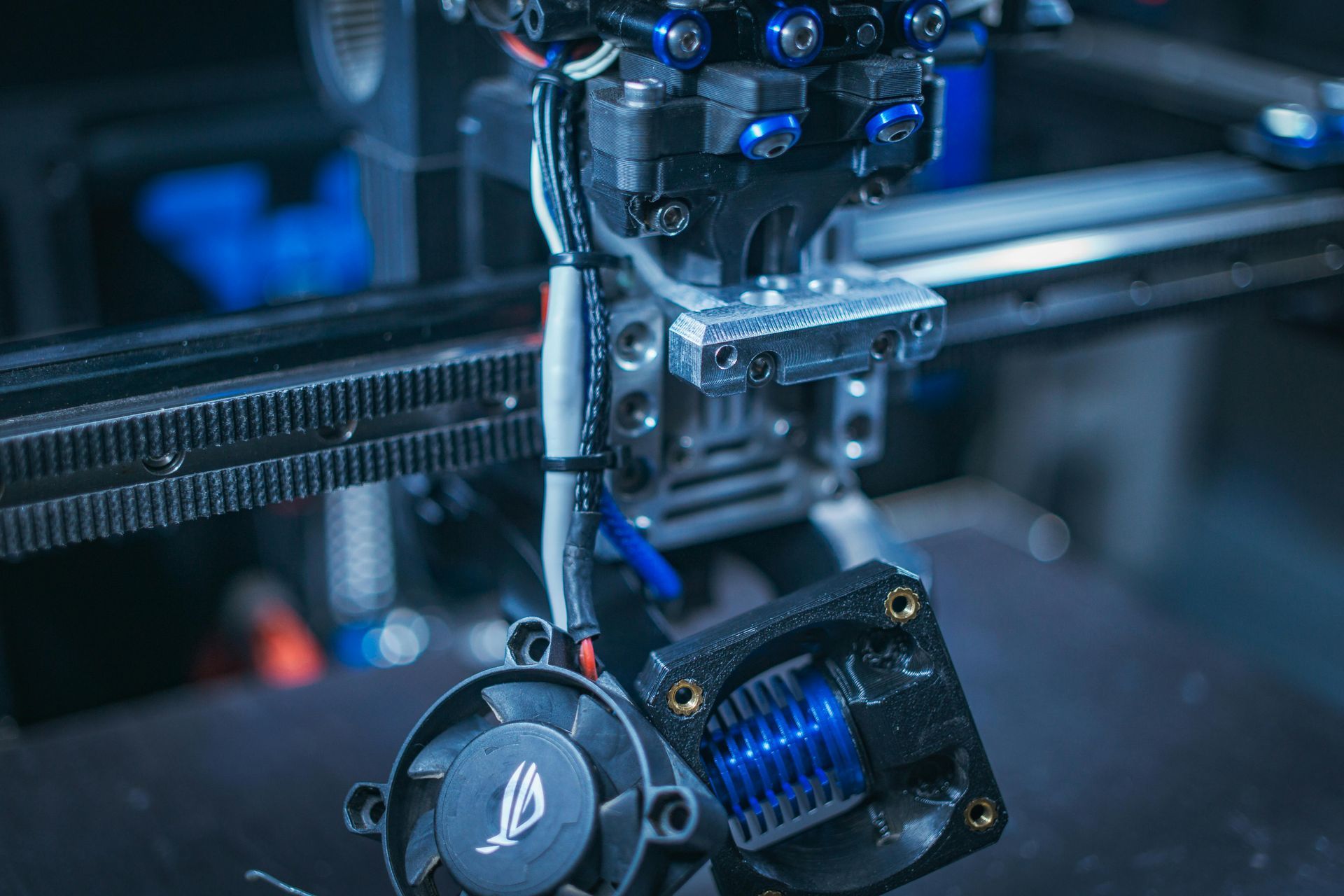

Precision Engineering With 3D Design

The medical device industry demands unparalleled precision, where even a minor error can lead to significant consequences. By3Design leverages state-of-the-art 3D modeling software and simulation tools to create highly accurate digital prototypes. These virtual models provide a clear visualization of the final product, enabling stakeholders to identify and address potential issues during the early stages of development. This precision minimizes costly revisions and ensures that devices meet exacting standards.

Accelerating Innovation Through 3D Design Consulting

Innovation in medical devices often involves pushing the boundaries of what’s possible, whether it’s developing advanced diagnostic tools, minimally invasive surgical instruments, or implantable devices. By3Design’s 3D design consulting services act as a catalyst for innovation by streamlining the development process and fostering creativity.

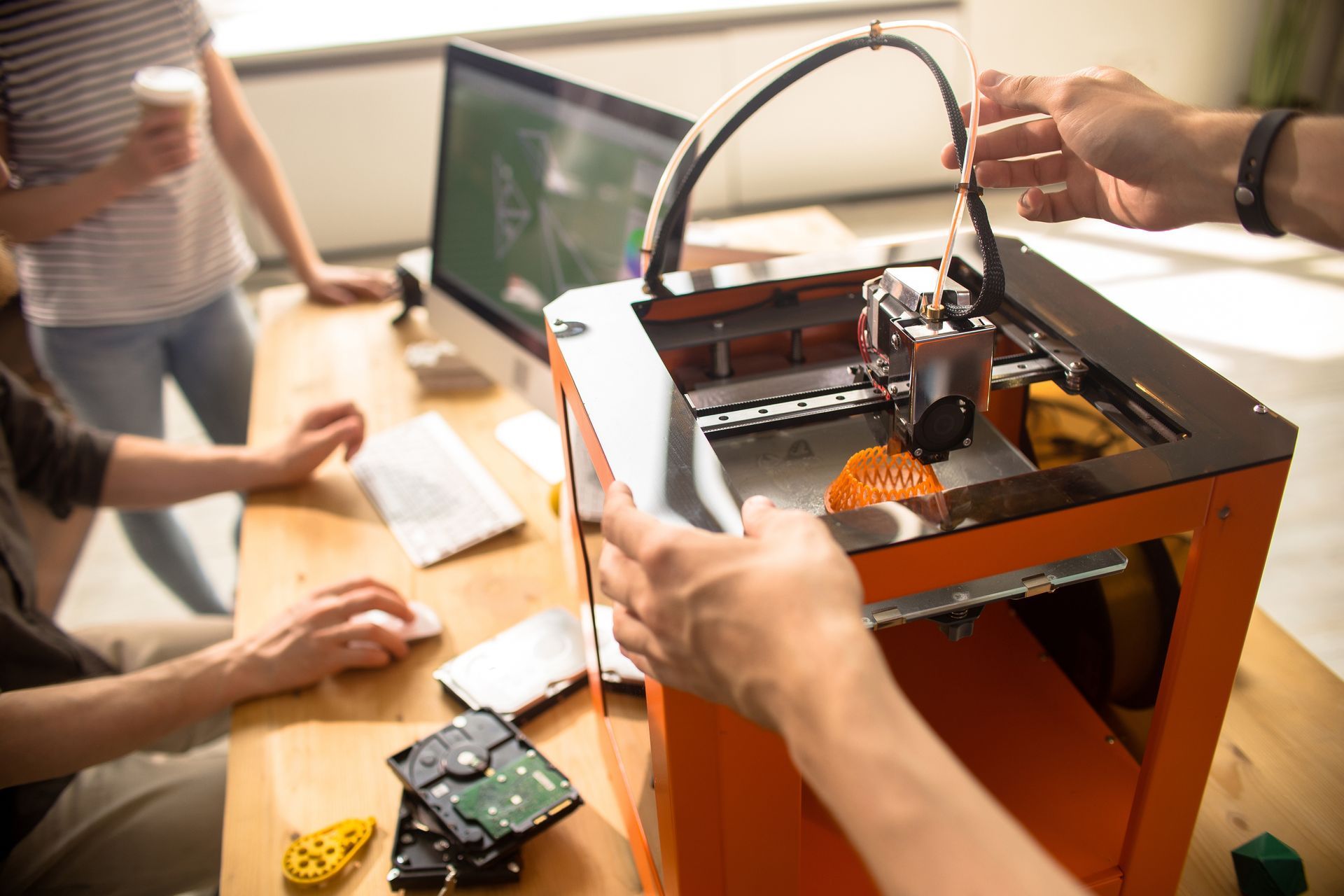

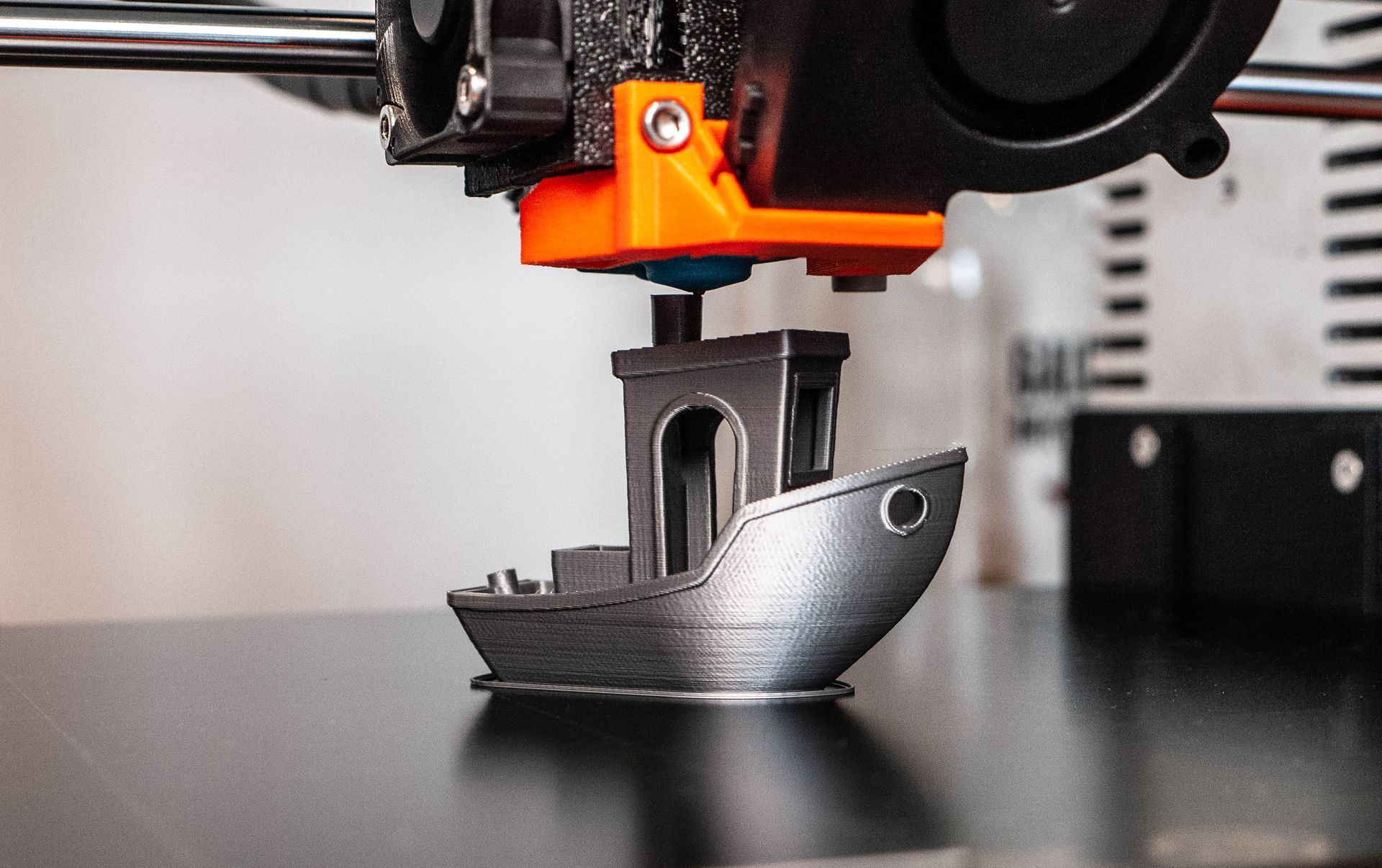

Prototyping And Iteration Made Easy

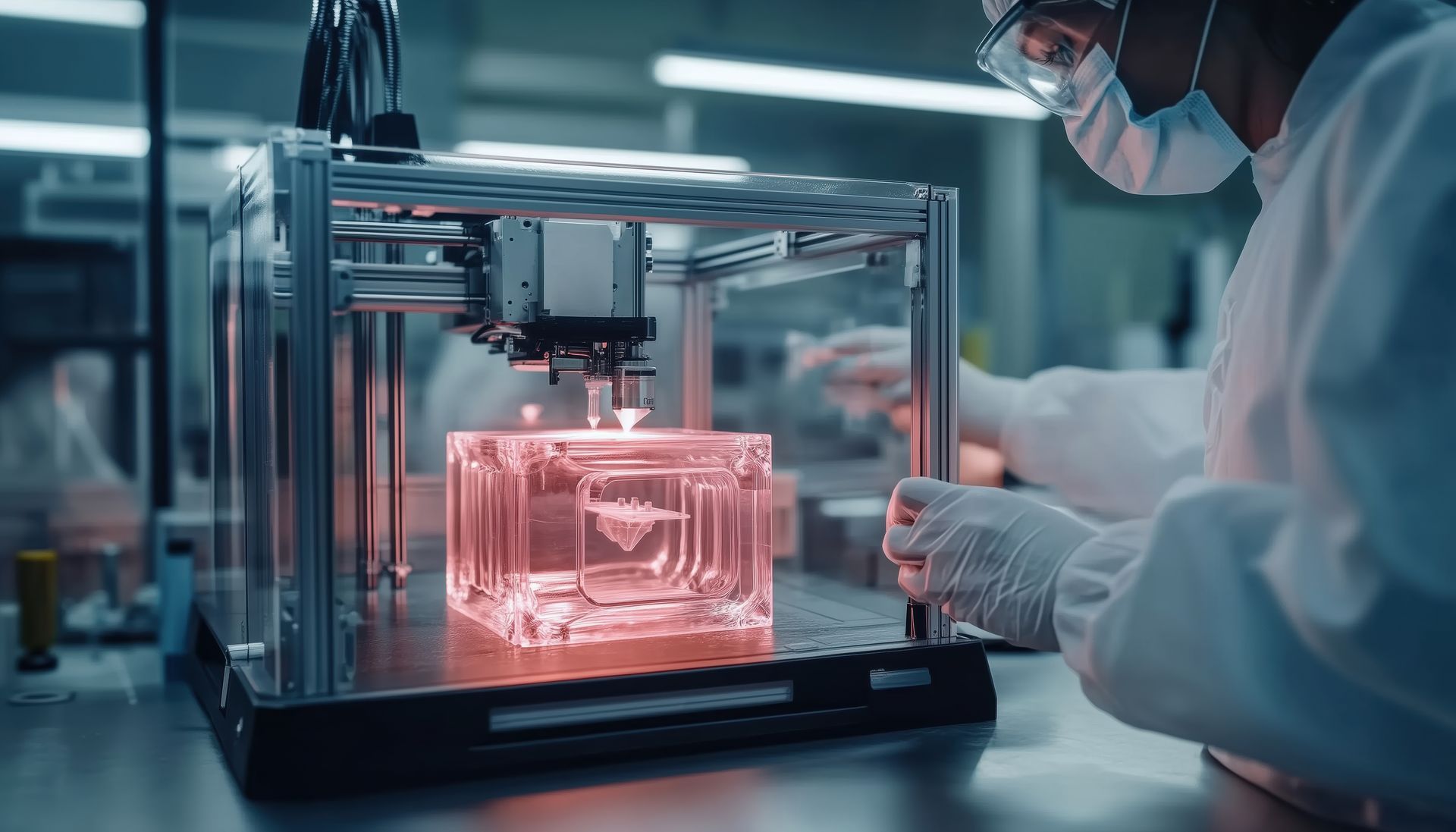

Traditional prototyping methods are often time-consuming and costly. By3Design’s expertise in 3D printing and rapid prototyping transforms this process, allowing for quick and cost-effective iterations. This capability is particularly valuable in the medical device industry, where prototypes must undergo rigorous testing before receiving regulatory approval.

With By3Design’s 3D design consulting, manufacturers can produce highly detailed prototypes that accurately represent the final product. These prototypes can be used for functional testing, ergonomic assessments, and even preliminary regulatory evaluations, significantly shortening the product development lifecycle.

Enhancing Customization And Patient-Specific Solutions

One of the most exciting applications of 3D design in the medical device industry is the ability to create patient-specific solutions. By3Design excels in designing custom implants, prosthetics, and surgical guides tailored to individual patient anatomies. Using advanced imaging technologies such as CT scans and MRI data, their team develops precise 3D models that ensure optimal fit and functionality. This level of customization not only improves patient outcomes but also sets a new standard for personalized healthcare.

Navigating Regulatory Challenges With Confidence

The medical device industry operates within a tightly regulated framework to ensure safety and efficacy. Navigating these complex regulations can be daunting, especially for startups and smaller companies. By3Design’s 3D design consulting services include a deep understanding of regulatory requirements, helping clients achieve compliance without compromising on innovation.

Designing For Manufacturability And Compliance

By3Design integrates compliance considerations into every stage of the design process. Their consultants are well-versed in FDA guidelines, ISO standards, and other regulatory frameworks, ensuring that designs meet all necessary criteria. This proactive approach reduces the risk of delays and rejections during the approval process.

Furthermore, By3Design focuses on designing for manufacturability (DFM), ensuring that products can be efficiently and reliably produced at scale. By addressing potential manufacturing challenges early in the design process, they help clients save time and resources while maintaining high-quality standards.

Collaborative Partnership For Success

What sets By3Design apart in the realm of 3D design consulting is their commitment to fostering collaborative partnerships with clients. They don’t just offer services—they become an extension of your team, working closely with stakeholders to understand their vision, goals, and challenges.

Tailored Solutions For Every Client

By3Design recognizes that no two projects are the same. Their consultants take a tailored approach to each engagement, offering customized solutions that align with the client’s specific needs. Whether it’s a startup looking to bring a novel idea to life or an established manufacturer aiming to enhance an existing product, By3Design delivers results that exceed expectations. Explore From Concept to Reality: The Process of 3D Printing a Product for more information.

Empowering Teams With Knowledge

Beyond delivering exceptional designs, By3Design prioritizes knowledge transfer, empowering their clients’ teams with the skills and insights needed to sustain success. Their consultants provide training, documentation, and ongoing support, ensuring that clients can confidently navigate future challenges.

The Future Of 3D Design In The Medical Device Industry

As we look to the future, the role of 3D design consulting in the medical device industry is poised to expand even further. Emerging technologies such as artificial intelligence (AI), machine learning, and generative design are becoming increasingly integrated into 3D design workflows, opening up new possibilities for innovation.

By3Design is at the forefront of these advancements, exploring how cutting-edge tools can enhance the design and development process. For example, AI-driven algorithms can analyze vast datasets to optimize device designs for performance and manufacturability. Generative design tools can propose novel geometries that maximize functionality while minimizing material usage. By staying ahead of these trends, By3Design ensures that their clients remain competitive in a rapidly evolving market.

Additionally, sustainability is becoming a key consideration in medical device design. By3Design is committed to helping clients reduce waste and improve energy efficiency through sustainable design practices. This not only benefits the environment but also aligns with the growing demand for eco-friendly solutions in healthcare.

Conclusion

As the medical device industry continues to evolve, the role of 3D design consulting will only grow in importance. By3Design is at the forefront of this evolution, driving innovation and excellence through their specialized services. Whether you’re a startup looking to disrupt the market or an established player aiming to stay competitive, partnering with By3Design ensures that your journey is marked by precision, efficiency, and success.

In the rapidly advancing landscape of medical technology, By3Design is more than a service provider, they are your trusted ally in bringing groundbreaking ideas to life. Experience the difference that expert 3D design consulting can make and join the ranks of innovators transforming healthcare with By3Design.

By3Design Blog