3D Printing Innovations: The Game-Changer In Aerospace

Phoenix, Arizona, is renowned for its thriving aerospace industry, where innovations fuel development in space exploration, defense, and aviation. A significant player in this technological evolution is 3D printing, which has revolutionized how aerospace companies design, prototype, and produce critical components. For By3Design, a leading 3D printing service in Phoenix, AZ, this technology serves as a gateway to creating cost-effective, high-precision solutions tailored to meet the unique demands of the aerospace sector. This blog will explore how 3D printing is reshaping Phoenix’s aerospace industry, the benefits it brings to the field, and why By3Design is at the forefront of this transformation.

Why 3D Printing Matters In Aerospace

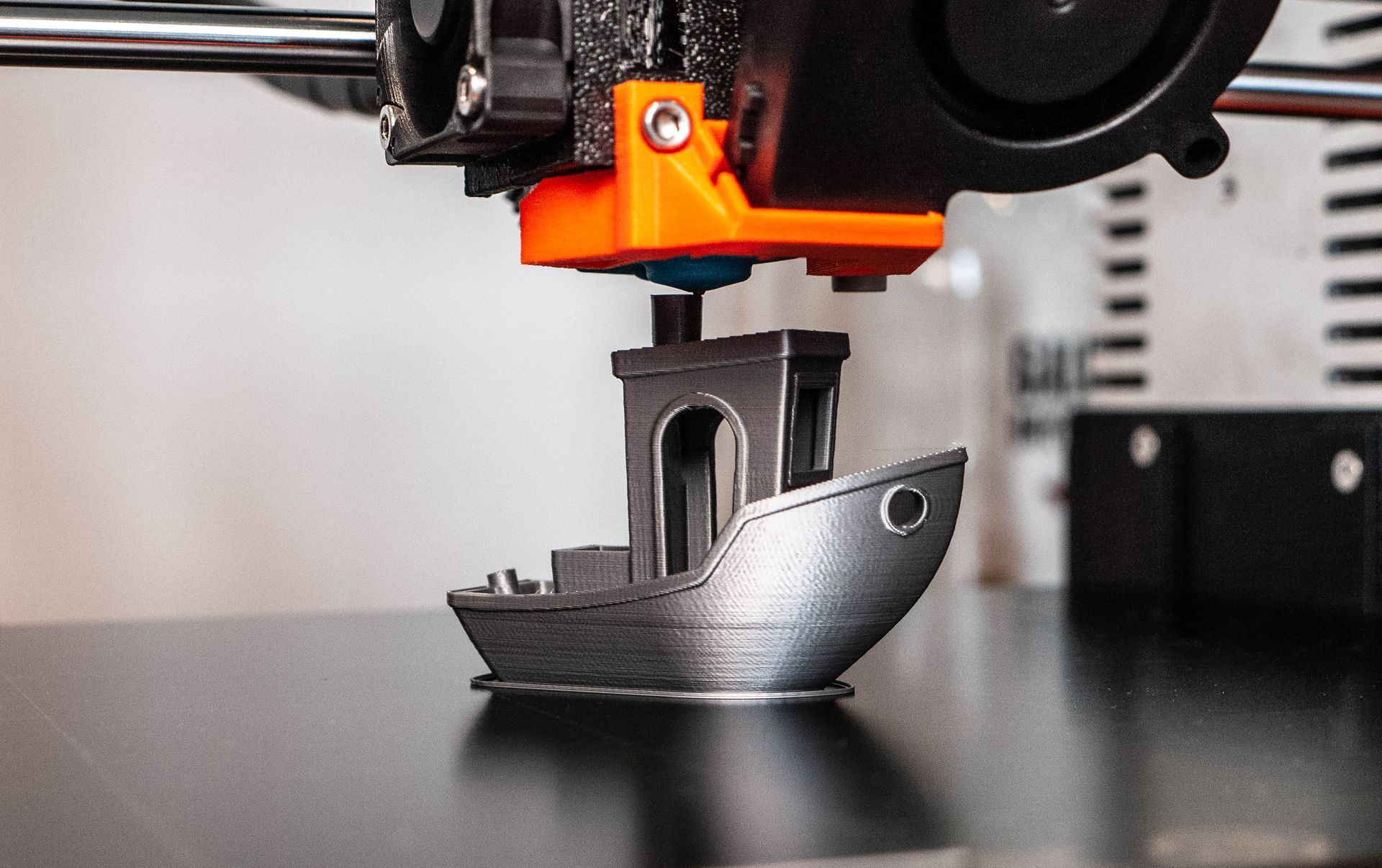

3D printing, or additive manufacturing, has brought a wave of innovation to many industries, but its impact on aerospace is especially transformative. Traditional aerospace manufacturing involves complex processes, with intricate parts requiring precision machining, skilled labor, and lengthy production times. 3D printing simplifies many of these challenges by enabling engineers to create lightweight, complex parts directly from digital models, which would otherwise be impossible or prohibitively expensive to produce.

Phoenix, being a major hub for aerospace with companies like Honeywell Aerospace, Raytheon, and others, provides an ideal landscape for integrating 3D printing. By3Design’s role here is crucial. Their advanced 3D printing capabilities make it easier for local companies to accelerate production cycles, enhance design flexibility, and reduce material waste—all while adhering to the rigorous standards required by the aerospace sector.

Key Advantages Of 3D Printing In Phoenix’s Aerospace Industry

Cost-Efficiency And Reduced Waste

The aerospace industry relies on high-quality materials like titanium, aluminum, and Inconel, all of which are costly. Traditional methods involve removing excess material, leading to significant waste. 3D printing, however, builds parts layer by layer, using only the necessary amount of material. This approach not only reduces costs but also minimizes environmental impact.

For Phoenix aerospace companies, By3Design’s 3D printing services offer an economical solution, as they can now prototype and produce parts without the high material expenses and waste associated with conventional manufacturing.

Rapid Prototyping And Shorter Production Cycles

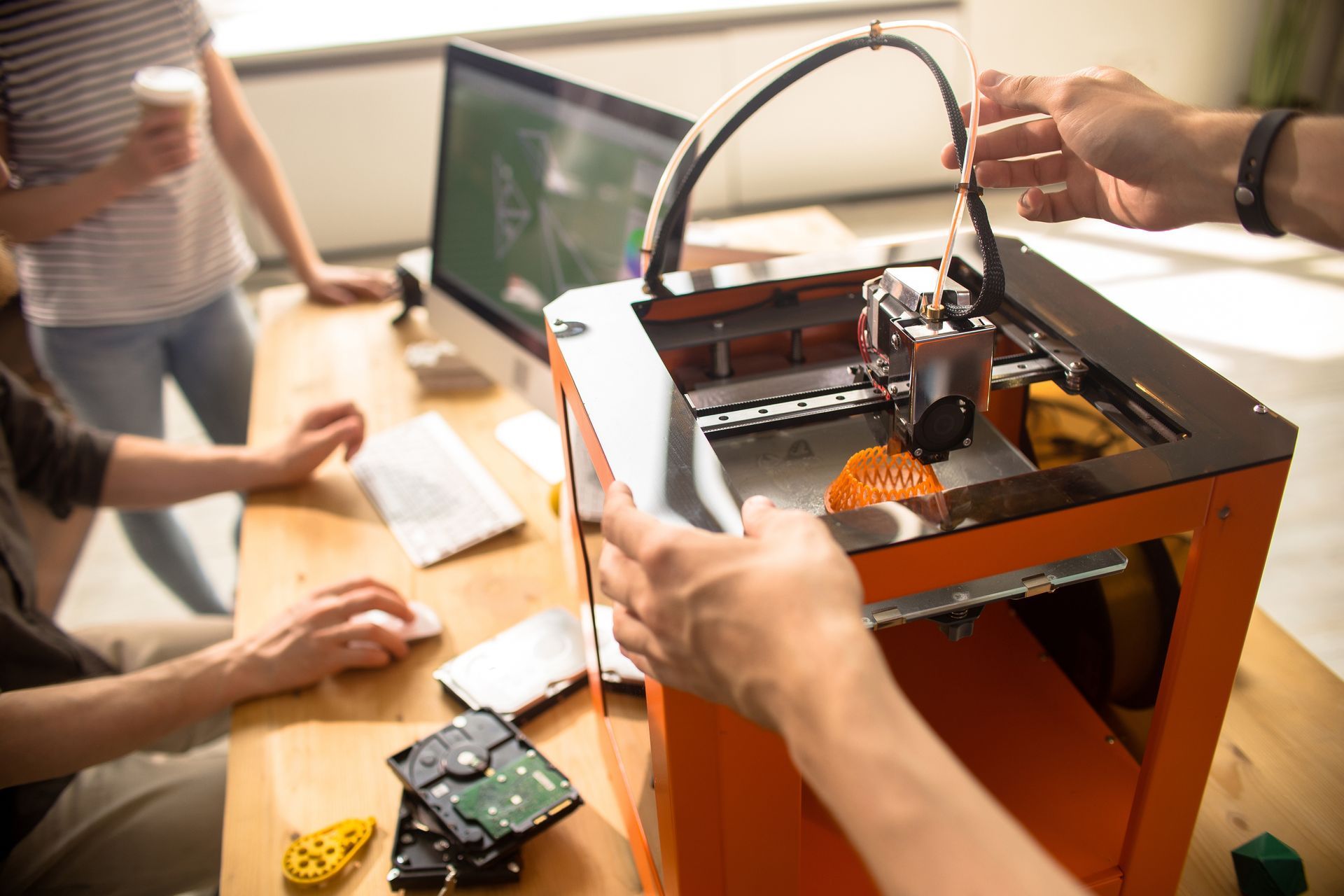

Aerospace companies operate in a fast-paced environment, where being able to prototype quickly can make a significant difference. With traditional methods, prototyping can take weeks or even months, and multiple iterations add to this timeline. 3D printing accelerates this process, allowing engineers to produce and test prototypes within days.

By3Design provides Phoenix-based companies with quick access to high-quality prototypes. The rapid turnaround time enables companies to bring products to market faster and stay competitive in a global aerospace industry that’s constantly evolving.

Design Flexibility And Innovation

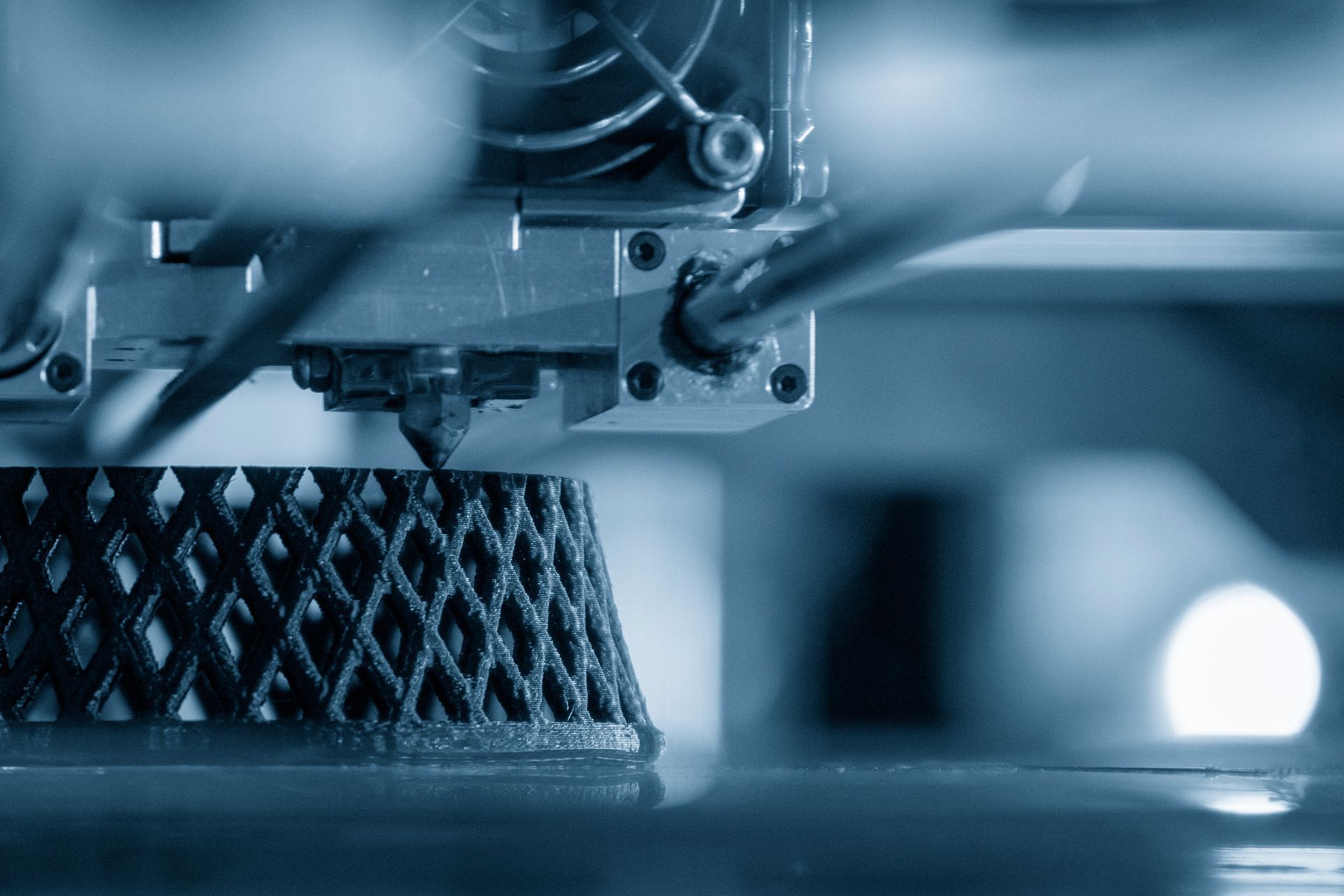

Aerospace components often have complex geometries, which can be challenging to achieve with conventional methods. 3D printing, however, offers unparalleled design freedom, allowing engineers to create intricate designs, lightweight structures, and integrated assemblies that would be impossible through traditional fabrication.

By3Design’s expertise in 3D printing enables aerospace companies to explore innovative designs, including lighter and more efficient components, which translate into reduced fuel consumption and lower emissions. This flexibility in design has proven particularly advantageous for aerospace companies focusing on sustainability—a growing concern in the industry. Click How To Calibrate Your Printer: 3D Printing Advice for more details.

On-Demand And Localized Manufacturing

The aerospace industry relies heavily on a global supply chain, which can be vulnerable to delays and disruptions. 3D printing allows companies to produce parts on demand, reducing reliance on extensive inventories or distant suppliers. In a strategic location like Phoenix, By3Design offers a local solution that reduces lead times and transportation costs, ensuring a steady supply of parts when they are most needed.

Local 3D printing production also adds resilience to the supply chain, which is invaluable for aerospace companies, especially those that support critical defense contracts or time-sensitive commercial projects.

3D Printing Applications In Phoenix’s Aerospace Sector

Lightweight Structural Components For Satellites

In satellite manufacturing, weight reduction is critical since launching payloads into orbit is incredibly costly. 3D printing enables the creation of lighter, structurally sound components, replacing traditionally heavy materials with complex, lightweight lattice structures. By3Design has collaborated with aerospace companies to develop satellite components that achieve the required strength-to-weight ratio while significantly reducing costs.

In one instance, By3Design’s 3D printing technology was used to create a satellite bracket with a 50% reduction in weight compared to the traditionally machined part. This not only lowered launch costs but also provided a robust solution capable of withstanding the harsh conditions of space.

Customized Parts For Aircraft Maintenance And Repair

Aircraft require regular maintenance and the replacement of certain parts to ensure safety and efficiency. Some of these parts may no longer be in production, especially for older aircraft models. 3D printing offers a solution by allowing companies to produce customized parts on demand, rather than waiting for traditional manufacturing lead times or scouring limited inventories.

By3Design works with maintenance teams in Phoenix to quickly fabricate replacement parts, from small fixtures to entire assemblies, ensuring minimal downtime for aircraft. Their on-demand production capabilities have become invaluable, particularly for the MRO (Maintenance, Repair, and Overhaul) sector.

Heat-Resistant Materials For Jet Engines

Jet engines operate at extreme temperatures and pressures, demanding parts made from heat-resistant alloys. 3D printing can utilize advanced materials like Inconel, a high-performance alloy known for its resistance to high temperatures, which is ideal for aerospace applications. By3Design’s expertise in printing with Inconel and other alloys allows Phoenix aerospace companies to produce jet engine parts that meet the necessary thermal and mechanical requirements.

By3Design has worked with local jet engine manufacturers to produce complex parts such as turbine blades and combustion liners, using 3D printing to achieve intricate designs with precise specifications. This capability not only enhances performance but also reduces lead times, an essential factor in meeting the high demands of the aerospace industry.

By3Design’s Role In Advancing 3D Printing In Phoenix’s Aerospace Sector

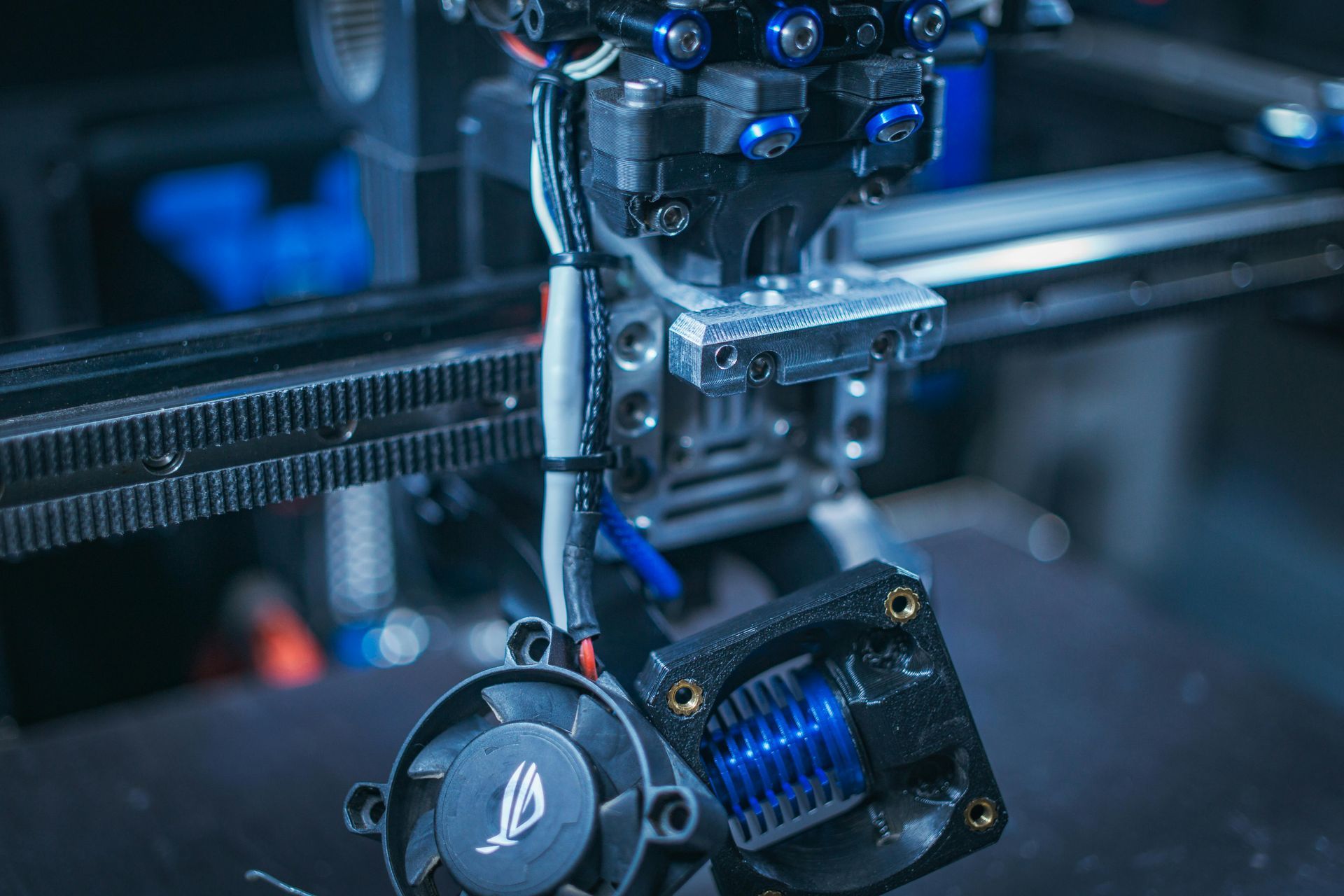

By3Design has become a cornerstone for the aerospace industry in Phoenix by providing cutting-edge 3D printing Phoenix AZ services that meet strict aerospace standards. Their facility houses a variety of 3D printers capable of working with different materials, including high-performance metals, thermoplastics, and composites, ensuring that they can cater to a broad range of aerospace applications.

By3Design also places a strong emphasis on quality control. Their rigorous testing and inspection processes ensure that every part meets industry standards and customer expectations. By investing in advanced quality assurance measures, such as CT scanning and laser inspection, By3Design guarantees that every component leaving their facility is ready for critical aerospace applications.

The Future Of 3D Printing In Phoenix’s Aerospace Industry

The trajectory for 3D printing in aerospace continues to climb as technology advances. In the future, Phoenix’s aerospace industry may see more extensive use of 3D printing in areas like space exploration, unmanned aerial vehicles (UAVs), and defense systems. By3Design is committed to staying at the forefront of this evolution, continually enhancing their capabilities and expanding their service offerings to meet the increasing demands of aerospace manufacturing.

A key area of focus for By3Design will likely be the development of hybrid manufacturing, combining traditional methods with additive techniques for parts that require a blend of high strength, reduced weight, and intricate designs. This approach could enable aerospace companies in Phoenix AZ to optimize manufacturing processes even further, reducing costs and improving efficiency.

Furthermore, the integration of artificial intelligence and machine learning with 3D printing technology could open up new possibilities. By3Design could leverage AI to enhance design automation, streamline production workflows, and improve predictive maintenance, ensuring their position as a leader in aerospace manufacturing innovation.

Conclusion

The role of 3D printing in Phoenix’s aerospace industry is transformative, offering a competitive edge in terms of cost, speed, and design flexibility. For aerospace companies in Phoenix, By3Design provides essential 3D printing services that drive innovation and efficiency. From lightweight components to custom-engineered solutions, By3Design enables aerospace companies to achieve unprecedented manufacturing capabilities, supporting Phoenix’s position as a hub for aerospace excellence.

By3Design’s commitment to quality, adaptability, and innovation makes them a pivotal partner for aerospace companies seeking to harness the full potential of 3D printing. As the aerospace industry continues to evolve, the role of 3D printing will only expand, and By3Design is poised to lead the charge in Phoenix, pushing the boundaries of what’s possible in aerospace manufacturing.

Reach out to us today!

By3Design Blog