A Beginner’s Guide to 3D Printing Materials

3D printing has revolutionized how we approach manufacturing and design, offering endless possibilities for creators and innovators alike. However, choosing the right material is a crucial first step in ensuring project success. With a variety of materials available, each tailored for specific needs, understanding their properties can help streamline the process. Whether you're creating prototypes or artistic pieces, 3D printing Phoenix services from By3Design can guide you to the best choice. This post explores popular 3D printing materials to help beginners choose the right option for their projects.

PLA: Affordable and Biodegradable

- Low Cost: PLA (Polylactic Acid) is an affordable material, making it ideal for beginners exploring 3D printing. It is widely available and offers good print quality without requiring advanced equipment, which helps keep initial costs low.

- Biodegradability: Made from renewable resources like cornstarch, PLA is biodegradable, making it environmentally friendly. It’s a popular choice for those prioritizing sustainability while still achieving reliable performance for their projects.

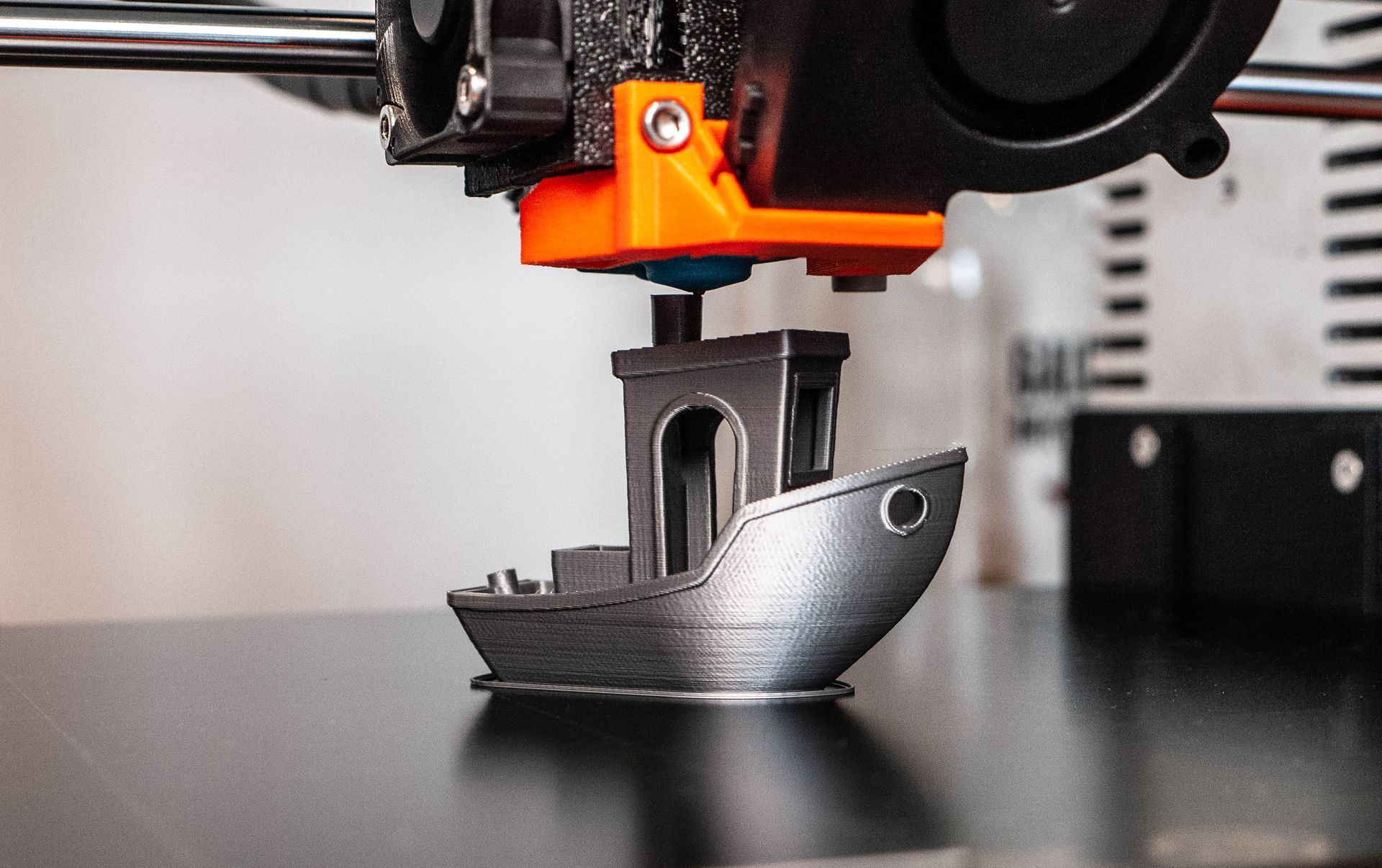

- Ease of Use: PLA is easy to work with due to its low melting temperature. It doesn’t require a heated bed, reducing complications during printing, and is less likely to warp compared to other materials.

- Versatility in Applications: PLA is ideal for hobby projects, decorative pieces, and prototypes. While it lacks high heat resistance and durability, it shines in projects where strength isn't the primary concern.

ABS: Durable and Heat-Resistant

- Strength and Durability: ABS (Acrylonitrile Butadiene Styrene) offers excellent toughness, making it ideal for parts requiring strength, such as functional prototypes, mechanical components, and toys.

- Heat Resistance: ABS can withstand higher temperatures than PLA, making it better suited for applications involving heat exposure. This feature ensures durability under varying conditions.

- Finishing Flexibility: ABS can be sanded, machined, or even acetone-smoothed for a polished finish. Its versatility in post-processing makes it a favorite for creating professional-grade items.

- Challenges in Printing: ABS requires a heated bed and controlled environment to prevent warping. While it offers superior properties, beginners may need guidance to successfully work with this material.

PETG: Food-safe and Impact-Resistant

- Food Safety: PETG (Polyethylene Terephthalate Glycol) is often used for food-safe applications like containers and utensils. Its low toxicity and smooth surface make it suitable for projects that require cleanliness.

- Impact Resistance: PETG is highly resistant to impact, offering strength and flexibility. It’s a great choice for products requiring durability, such as outdoor tools and protective covers.

- UV and Chemical Resistance: PETG stands up well against UV rays and chemical exposure, making it an excellent material for outdoor or industrial applications where resilience is key.

- Easy Printing Properties: Combining the ease of PLA and strength of ABS, PETG prints without significant warping and has good adhesion between layers, ensuring consistent results. Learn more about other 3D printing materials and their pros and cons when you read “3D Printing: What Materials Can You 3D Print With?”

Nylon: Flexible and Strong

- Flexibility: Nylon’s unique combination of flexibility and strength makes it suitable for projects like hinges, gears, and wearable items. It can endure repeated stress without breaking.

- High Strength-to-Weight Ratio: Despite its low weight, this material is incredibly strong. It’s ideal for applications requiring durable yet portable parts, such as automotive and aerospace components.

- Moisture Sensitivity: Nylon absorbs moisture from the environment, which can affect its print quality. Proper storage in a dry environment is crucial to maintain its integrity during printing.

- Post-Processing Options: Nylon can be dyed or polished, allowing for creative and functional enhancements. It’s perfect for advanced users looking to customize their prints.

Resin: High Detail and Smooth Finish

- Exceptional Detail: Resin is used in SLA (Stereolithography) printers, providing unmatched precision and intricate detailing. It’s ideal for jewelry, dental models, and other high-resolution projects.

- Smooth Surface Finish: Resin prints have a naturally smooth finish, reducing the need for extensive post-processing. This feature makes it ideal for creating presentation-quality models and prototypes.

- Material Options: There are various resin types, including tough, flexible, and castable, offering versatility for different applications. This variety makes it a flexible choice for specialized projects.

- Printing Considerations: Resin printing requires post-curing and careful handling due to its toxicity in liquid form. While it offers high-quality results, users should be prepared for additional steps in the process.

Metal Filaments: For Industrial or Artistic Applications

- Industrial Applications: Metal filaments, often a mix of metal powder and plastic, are great for creating sturdy and heat-resistant components. They’re used in aerospace, automotive, and industrial manufacturing.

- Artistic Designs: These filaments produce metallic finishes, making them ideal for sculptures, jewelry, and decorative items. Their unique aesthetic appeal enhances creative projects.

- High-Performance Properties: Metal filaments offer the strength of metal while remaining printable on modified FDM printers. This combination makes them a practical option for advanced projects.

- Equipment Requirements: Printing with metal filaments often requires hardened nozzles to avoid wear and tear. Advanced users benefit most from these specialized materials.

Comparison of Cost, Ease of Use, and Environmental Impact

- Cost: PLA and PETG are more affordable, while ABS and Nylon sit in the mid-range. Resin and metal filaments are premium options due to their specialized properties.

- Ease of Use: PLA and PETG are beginner-friendly, while ABS and Nylon require more experience due to their technical demands. Resin and metal filaments need specific equipment and handling expertise.

- Environmental Impact: PLA is biodegradable, making it the most eco-friendly choice. PETG and Nylon are recyclable but not biodegradable. Resin and metal filaments have higher environmental footprints due to production and disposal challenges.

Conclusion

Choosing the right material for your 3D printing project is a balance between performance, cost, and application. Each material offers distinct advantages, catering to diverse needs. For those in need of guidance, 3D printing services offered by By3Design can simplify the decision and help bring your designs to life. With the right material, your 3D printing journey can lead to extraordinary results, no matter your expertise.

Ready to bring your vision to life with expert 3D printing?

By3Design is here to help you navigate the world of materials and technology. From PLA to metal filaments, their team ensures you choose the best fit for your project. With cutting-edge equipment and personalized advice, you’re guaranteed top-notch results.

Contact our team today

and watch your ideas take shape!

By3Design Blog