Advanced 3D Printing: Mastering Supports With By3Design

In the heart of Arizona, where innovation meets creativity, By3Design is leading the charge in the realm of 3D printing. The company has gained recognition for its expertise in advanced 3D printing techniques, enabling individuals and businesses to push the boundaries of what’s possible.

Whether you're an entrepreneur prototyping a product or a hobbyist looking to perfect your craft, understanding advanced techniques like support structures, infill patterns, and material optimization can make all the difference.

This blog dives into these cutting-edge methods and explains how By3Design leverages them to empower the vibrant 3D printing community in Arizona.

The Growing Demand For 3D Printing In Arizona

Arizona has become a hotbed for technological innovation, and 3D printing is at the forefront of this movement. From aerospace and healthcare to art and education, industries across the state are embracing the possibilities of additive manufacturing.

By3Design stands out by offering tailored solutions to meet the unique needs of these industries. But what truly sets them apart is their focus on helping customers master advanced techniques, ensuring high-quality, functional, and aesthetically pleasing prints.

Why Advanced 3D Printing Techniques Matter

Mastering 3D printing Arizona isn’t just about hitting "print" on a machine. It involves understanding how to optimize designs for durability, appearance, and cost-efficiency. Techniques like support structure placement, infill pattern selection, and material choice play crucial roles in achieving professional-grade results.

By3Design specializes in guiding clients through these nuanced processes, helping them unlock the full potential of 3D printing in Arizona's dynamic marketplace.

Demystifying Support Structures

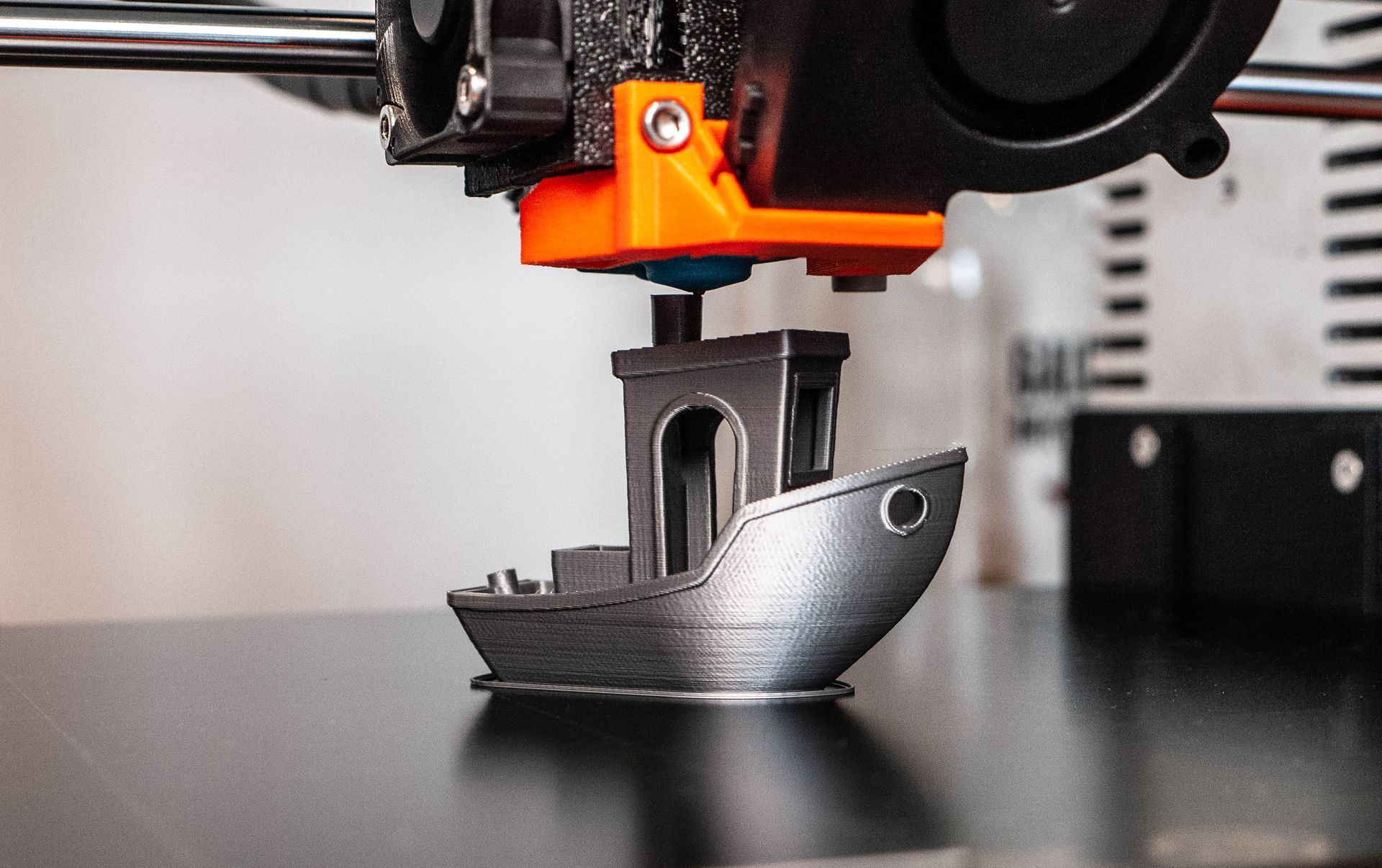

Supports are often the unsung heroes of successful 3D printing. They provide temporary scaffolding to ensure complex or overhanging parts print correctly. However, improper support placement can lead to wasted material, extended print times, and surface imperfections.

Types Of Supports

By3Design educates users on two main types of supports:

- Tree-Like Supports: Ideal for reducing material usage and minimizing marks on finished prints.

- Linear Supports: Provide robust stability but may require more post-processing.

Strategic Placement

Strategically placing supports can reduce post-processing time and improve surface finish. By3Design uses advanced slicing software to analyze models and determine the optimal support configuration, ensuring a balance between stability and efficiency.

Dissolvable Supports

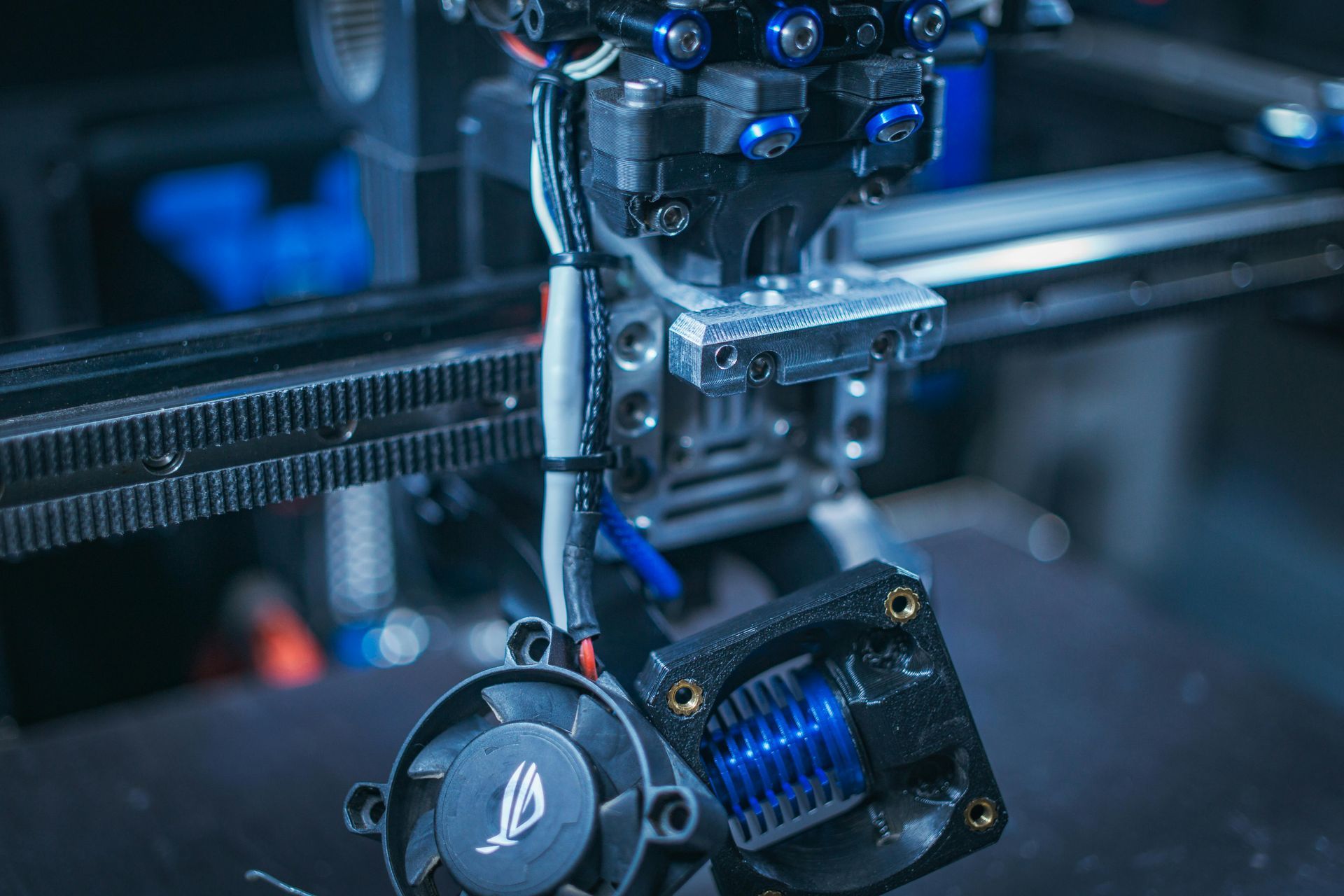

For intricate designs, dissolvable supports made from materials like PVA or HIPS are a game-changer. By3Design’s printers are equipped to handle dual-extrusion setups, enabling the use of dissolvable materials for a cleaner finish and easier removal.

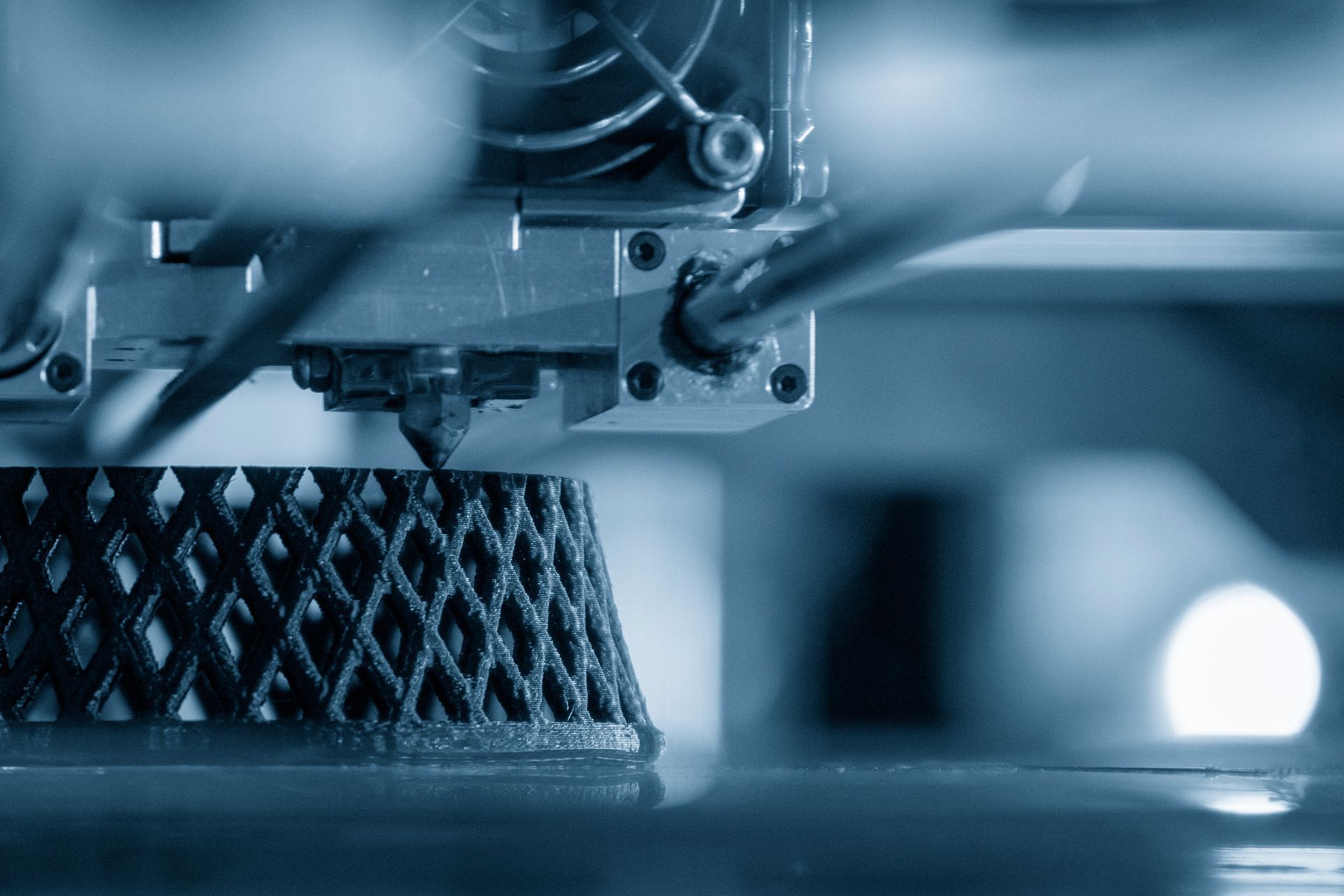

The Art And Science Of Infill Patterns

Infill patterns are another critical factor that can dramatically impact the strength, weight, and material usage of a 3D print. By3Design helps clients understand and experiment with various infill types to meet their specific needs.

Common Infill Patterns

- Rectilinear: A basic grid-like pattern, ideal for general-purpose prints.

- Honeycomb: Offers excellent strength-to-weight ratio, perfect for functional parts.

- Gyroid: Balances strength and flexibility while minimizing material usage.

Application-Specific Infill

By3Design emphasizes that different projects require different infill strategies. For instance:

- Prototypes: Lightweight and fast-to-print patterns like zig-zag or low-density honeycomb.

- Functional Parts: Dense patterns such as cubic or gyroid for enhanced durability.

- Aesthetic Models: Sparse infill to save time and material while maintaining visual appeal.

By fine-tuning infill settings, clients can reduce material costs and achieve optimal performance, making this an essential skill for 3D printing enthusiasts in Arizona.

Mastering Layer Heights And Print Speeds

Layer height and print speed are often overlooked but significantly influence print quality and time. By3Design offers hands-on workshops to help clients find the right balance for their projects.

Layer Heights

- Fine Detail: Thin layers (0.1mm or less) capture intricate details but extend print times.

- Rapid Prototyping: Thicker layers (0.2mm or more) provide faster prints with reduced detail.

Print Speeds

By3Design demonstrates how to optimize print speeds without sacrificing quality. Factors such as nozzle size, material type, and cooling settings are carefully considered to achieve the best results.

Advanced Materials For 3D Printing

Arizona’s diverse industries require equally diverse materials. By3Design offers expertise in a wide range of filaments, from standard PLA and ABS to high-performance materials like carbon fiber-infused nylon, TPU, and metal composites.

Material-Specific Techniques

Each material has unique properties that affect print settings and post-processing:

- Flexible Filaments (TPU): Require slower speeds and specialized nozzles to prevent clogging.

- Metal Composites: Need precise temperature control for a smooth finish.

- High-Temperature Polymers (PEEK, PEI): Demand industrial-grade printers capable of maintaining high chamber temperatures.

By3Design’s advanced equipment and knowledgeable staff ensure clients can experiment with these materials confidently, expanding their creative and functional possibilities.

Leveraging Arizona’s 3D Printing Ecosystem

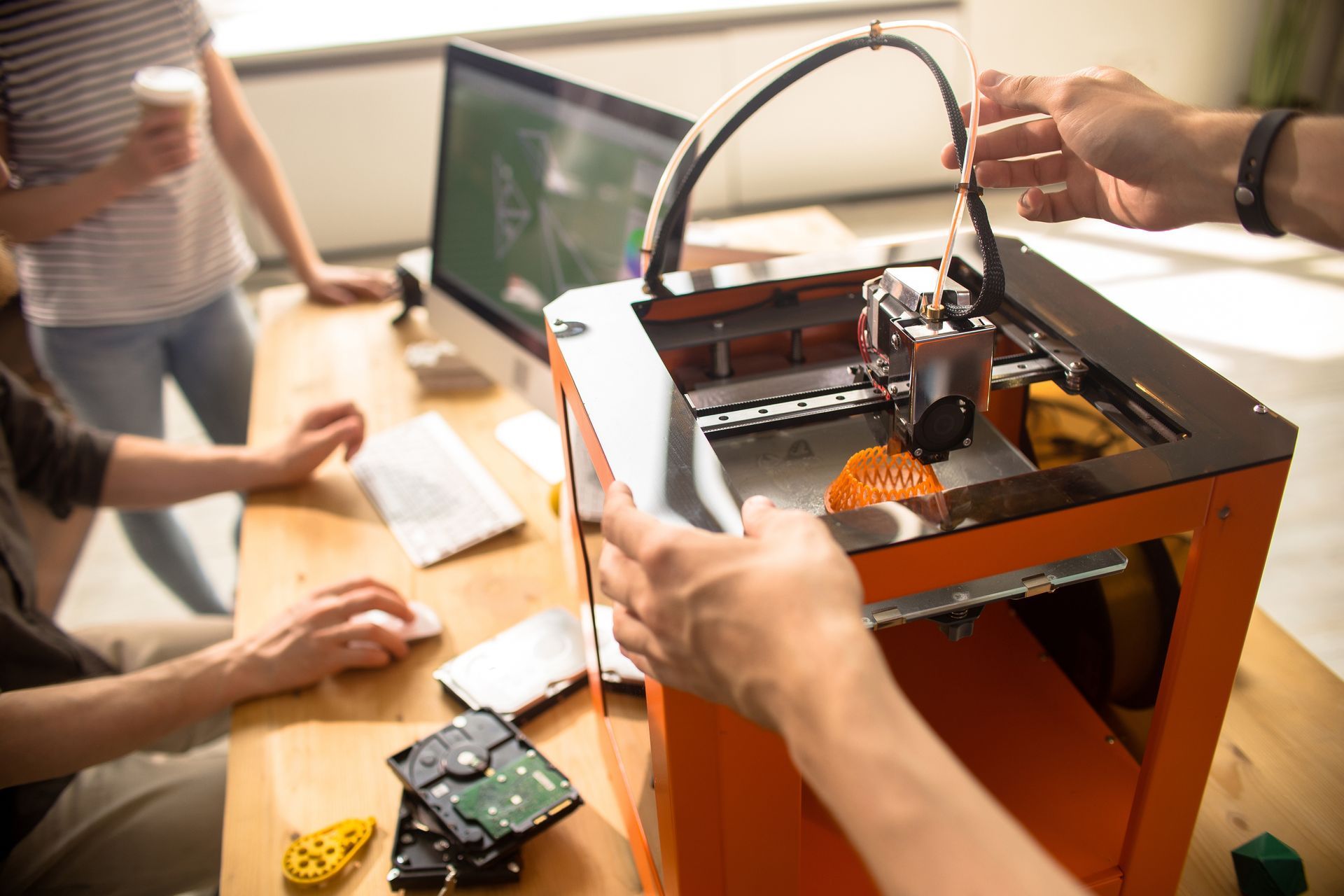

Arizona is home to a vibrant community of makers, innovators, and businesses eager to explore 3D printing. By3Design not only provides state-of-the-art printing services but also fosters collaboration through workshops, meetups, and partnerships with local organizations.

Education And Training

From beginners to seasoned professionals, By3Design offers tailored training sessions to help clients master advanced techniques. Their step-by-step guidance ensures that anyone can achieve exceptional results, regardless of experience level.

Community Projects

By3Design actively collaborates with Arizona schools, universities, and businesses to bring 3D printing to the forefront of education and industry. These initiatives are inspiring the next generation of innovators and showcasing the transformative potential of 3D printing.

Why Choose By3Design For 3D Printing In Arizona?

By3Design is more than just a 3D printing service provider; it’s a partner in innovation. Their commitment to empowering clients with advanced techniques sets them apart in Arizona’s competitive market.

Personalized Solutions

By3Design takes the time to understand each client’s unique needs, offering customized advice on supports, infill patterns, materials, and more. Explore 3D Printing for Entrepreneurs: Turning Ideas into Reality for more information.

Cutting-Edge Technology

Their investment in high-end printers and software ensures precise, reliable, and professional results for every project.

Community-Centered Approach

By3Design’s dedication to education and collaboration makes them a cornerstone of Arizona’s 3D printing community.

Conclusion

For anyone in Arizona looking to master 3D printing, By3Design is the ultimate resource. Their expertise in advanced techniques like support structures, infill patterns, and material optimization empowers clients to create exceptional prints that meet both aesthetic and functional demands.

As 3D printing continues to reshape industries across Arizona, By3Design remains at the forefront, helping individuals and businesses unlock the full potential of this revolutionary technology. Whether you’re a hobbyist or a professional, their guidance ensures that you’re equipped to tackle even the most complex projects with confidence.

Explore the future of 3D printing in Arizona with By3Design and elevate your creations to new heights.

By3Design Blog