Best 3D Printing Services: By By3Design

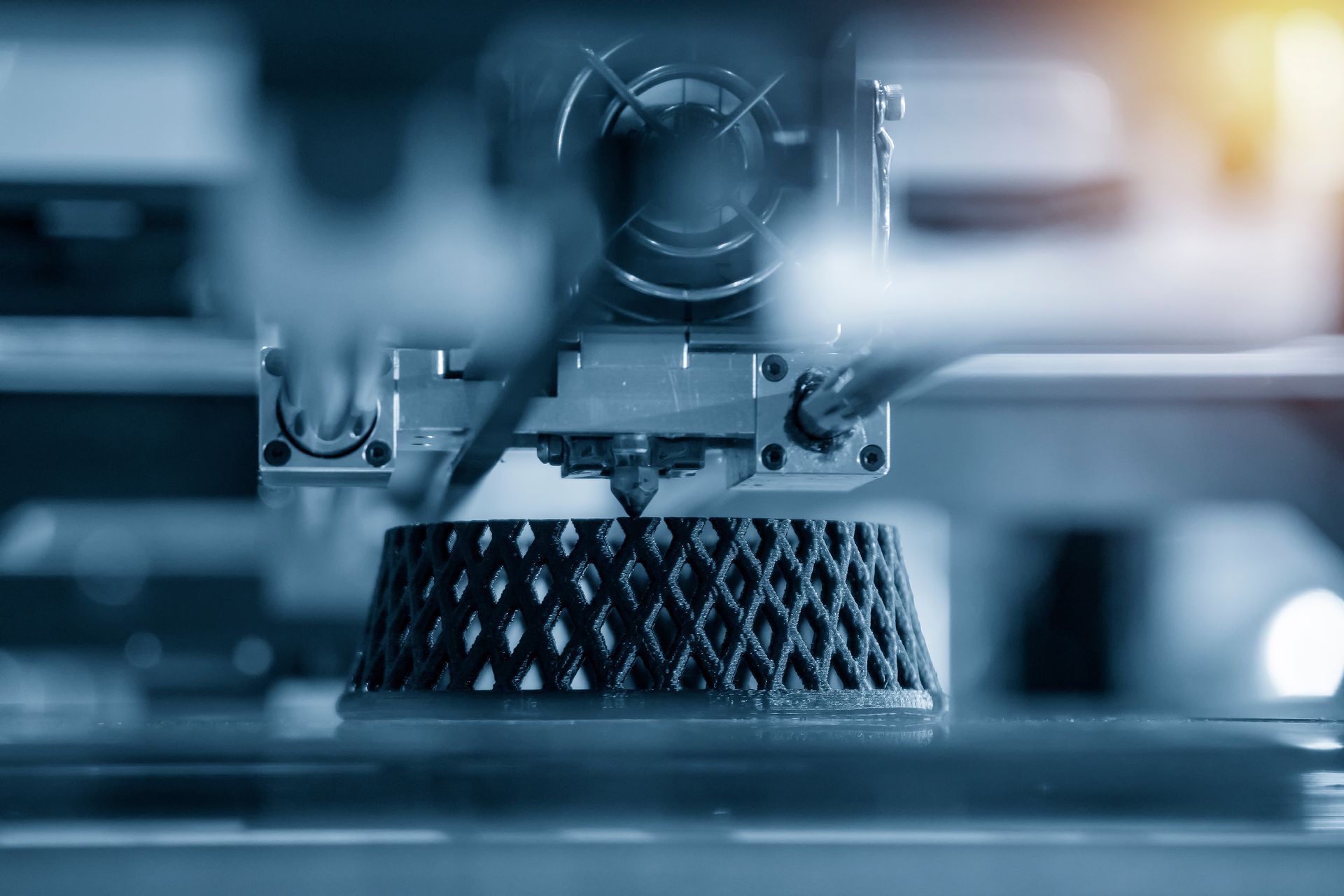

Phoenix, Arizona, is known for innovation and technology. Rapid prototyping and additive manufacturing are important in many industries here. As 3D printing becomes more popular in Phoenix, we must understand the challenges of the desert climate. This blog will look at how Phoenix's weather affects 3D printing. It will talk about the right technologies to use and suggest some of the best 3D printers in the Phoenix area, including Scottsdale. This way, your additive manufacturing projects can succeed in Arizona.

Understanding Phoenix's Climate And 3D Printing

Phoenix has very hot weather. It has low humidity and a lot of sunshine. While these things can be nice, they can create big challenges for 3D printing. The high heat can change how materials behave. This can lead to issues like warping, cracking, and parts not being the right size.

Also, low humidity can make materials strong but also very brittle. They may break easily when printing or afterwards. So, it is important to know how these weather conditions affect 3D printing. This knowledge helps get good and reliable results in Phoenix.

The Impact Of Dry Heat On 3D Printing Materials

Different materials for 3D printing in Phoenix AZ react in various ways to heat. ABS (Acrylonitrile Butadiene Styrene) is strong and durable. However, it can also warp and shrink when exposed to high temperatures. This may cause measuring errors and weaken the final printed object.

On the other hand, PLA (Polylactic Acid) is biodegradable and easier to print. It tends to soften and lose shape when heated, particularly during printing. PETG (Polyethylene Terephthalate Glycol-modified) is a strong and flexible choice. It handles heat better than PLA but can still have problems in high temperatures.

Because of this, choosing the right material based on how it reacts to heat is important. Also, knowing how these materials respond under the specific conditions in Phoenix will help you make smart choices. This will lead to better quality in 3D printing.

Adapting 3D Printing Processes For High Temperatures

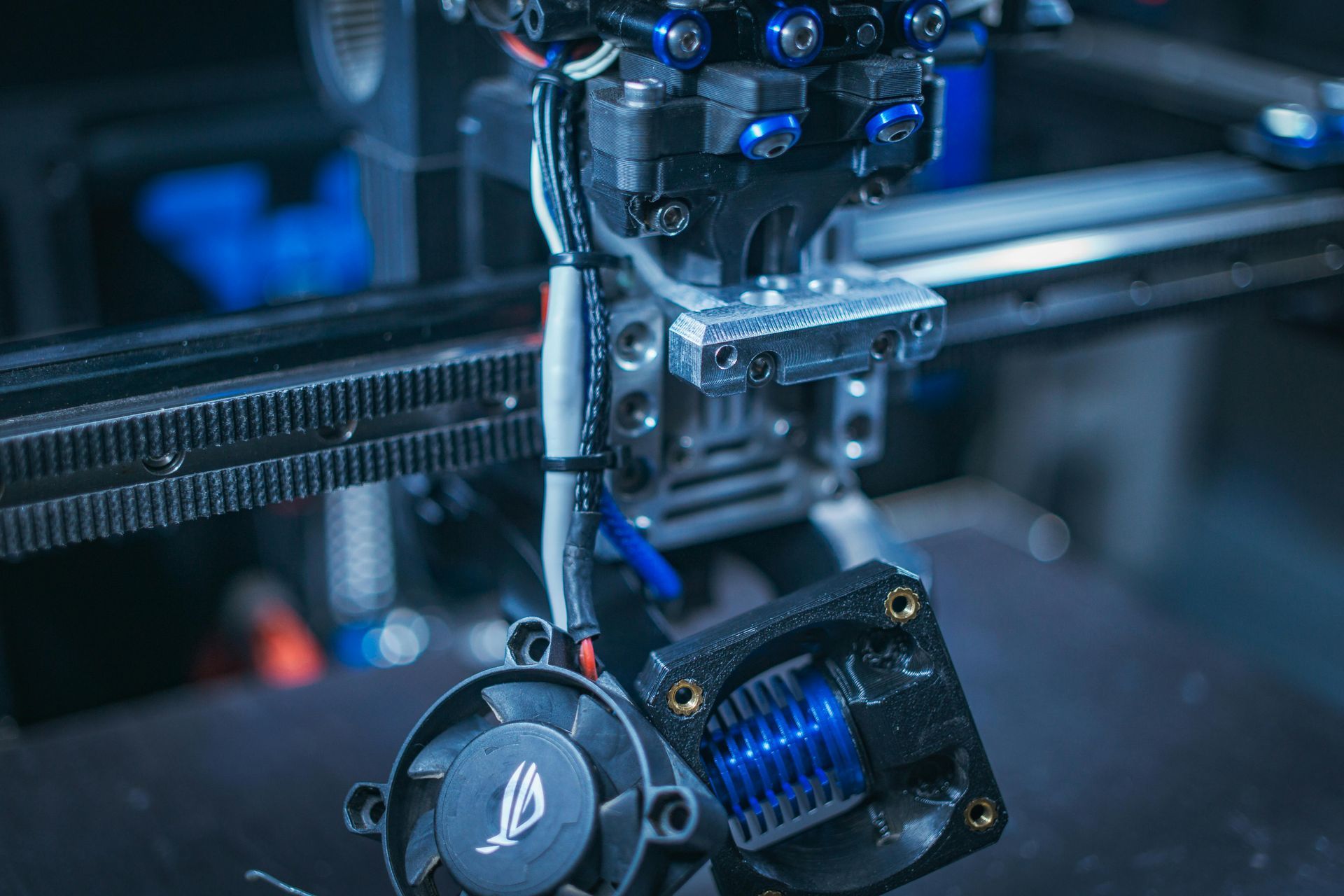

Adjusting your 3D printing setup is very important when you are in a hot place like Phoenix. Using enclosures is a good idea to reduce the effects of changing temperatures during the printing process. This type of control helps manage temperature and airflow, which leads to better and more reliable results.

For FDM (Fused Deposition Modeling) printing, it's important to set the right printing temperature and cooling settings. Think about using a lower printing temperature for materials such as ABS and PLA, as this can help reduce costs. Understanding the impact of material type on cost is crucial for achieving affordable 3D prints. Changing the cooling fan speeds can also affect the quality of your print. Good cooling is necessary for layers to stick together and to avoid warping.

Also, it’s very important to store your filaments properly in a dry place. Keep them in airtight containers with desiccant packs. This will stop moisture from getting in, which can harm your printing performance and the materials during rapid prototyping.

Top 3D Printing Technologies For Phoenix's Environment

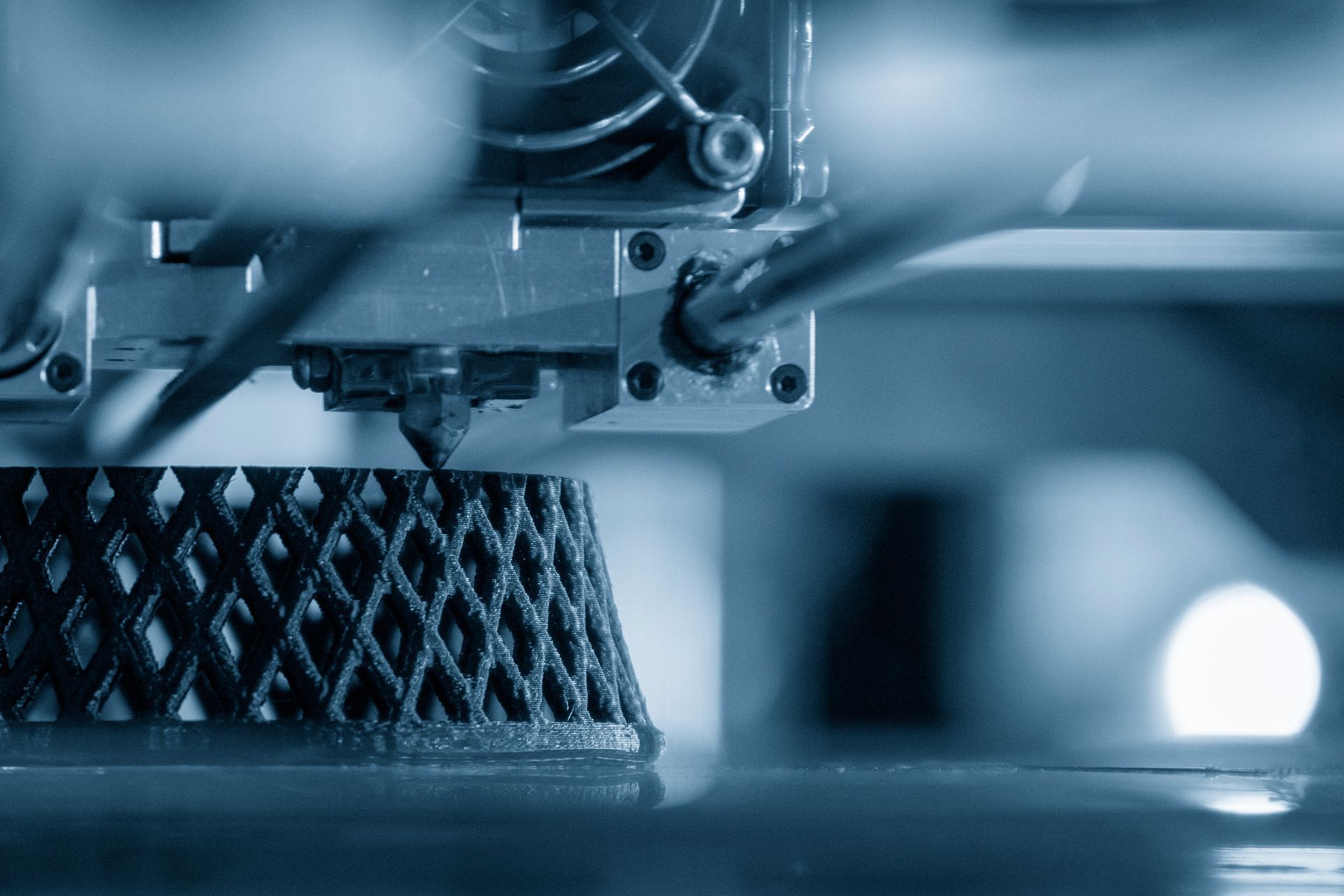

In Phoenix's hot climate, some 3D printing methods work better than others. FDM is a popular choice because it can use many materials and is very versatile. Still, it needs some changes to handle the high temperatures that can affect how accurate and reliable the prints are.

SLA, or Stereolithography, is known for making high-resolution prints with smooth surface finishes. It can be a great option in Phoenix if you pick the right resin and use post-processing methods to help it resist heat better.

Fused Deposition Modeling (FDM) In Arid Conditions

Fused Deposition Modeling (FDM) technology works well in dry places like Phoenix, AZ. It creates 3D objects by layering materials. This makes it great for quick prototypes. In dry weather, you may need to change some things for temperature and humidity. This helps keep the printed items' quality high. FDM printers usually use materials like PLA, ABS, and PETG. These materials can react differently to dry air, making it important to choose the right materials for FDM printing in Phoenix, AZ. Additionally, FDM technology can be enhanced with Material Jetting (MJ) - Multi Jet Fusion (MJF) 3D printing Phoenix AZ services, which offer even faster and more powerful production capabilities in arid conditions.

Stereolithography (SLA) Adjustments For Heat

Stereolithography (SLA) printing in hot places like Phoenix, AZ, can be tricky. The heat can affect how your prints turn out, especially when printing on a large scale. To deal with this heat, you should make some adjustments to your SLA printer. First, lower the resin exposure time to slow down curing that happens too fast in the heat. Also, keep an eye on the build platform temperature, so your prints don’t warp. These changes are crucial for achieving high-quality prints, especially in hot areas like Arizona. Spending time on setting up your printer for heat can help you get better SLA prints.

By3Design's Picks: Best 3D Printers For Phoenix

At By3Design, we know how important it is to pick the right 3D printer for Phoenix's special environment. We have put together a list of high-quality 3D printers that can manage the tough challenges of heat and dry air.

We look at things like enclosed build chambers, heated beds, material compatibility, and how reliable the printers are. Our team of experts is here to help you choose the best 3D printing technologies and materials for your needs. This way, you can get the best results every time you print.

Model 1: Features And Climate Suitability

| Feature | Description | Impact on Phoenix Climate Suitability |

|---|---|---|

| Technology | Powder Bed Fusion (PBF) | Well-suited for Phoenix's climate as the powder bed acts as an insulator, promoting even cooling and reducing the risk of warping. |

| Build Chamber | Enclosed | Essential for maintaining a stable printing environment and minimizing the impact of ambient temperature fluctuations. |

| Material Compatibility | Wide range of materials, including Nylon PA12, TPU, and high-performance polymers. | Provides options for heat-resistant materials suitable for Phoenix's climate. |

| Layer Resolution | Fine layer resolution down to 20 microns | Enables the production of highly detailed and accurate parts. |

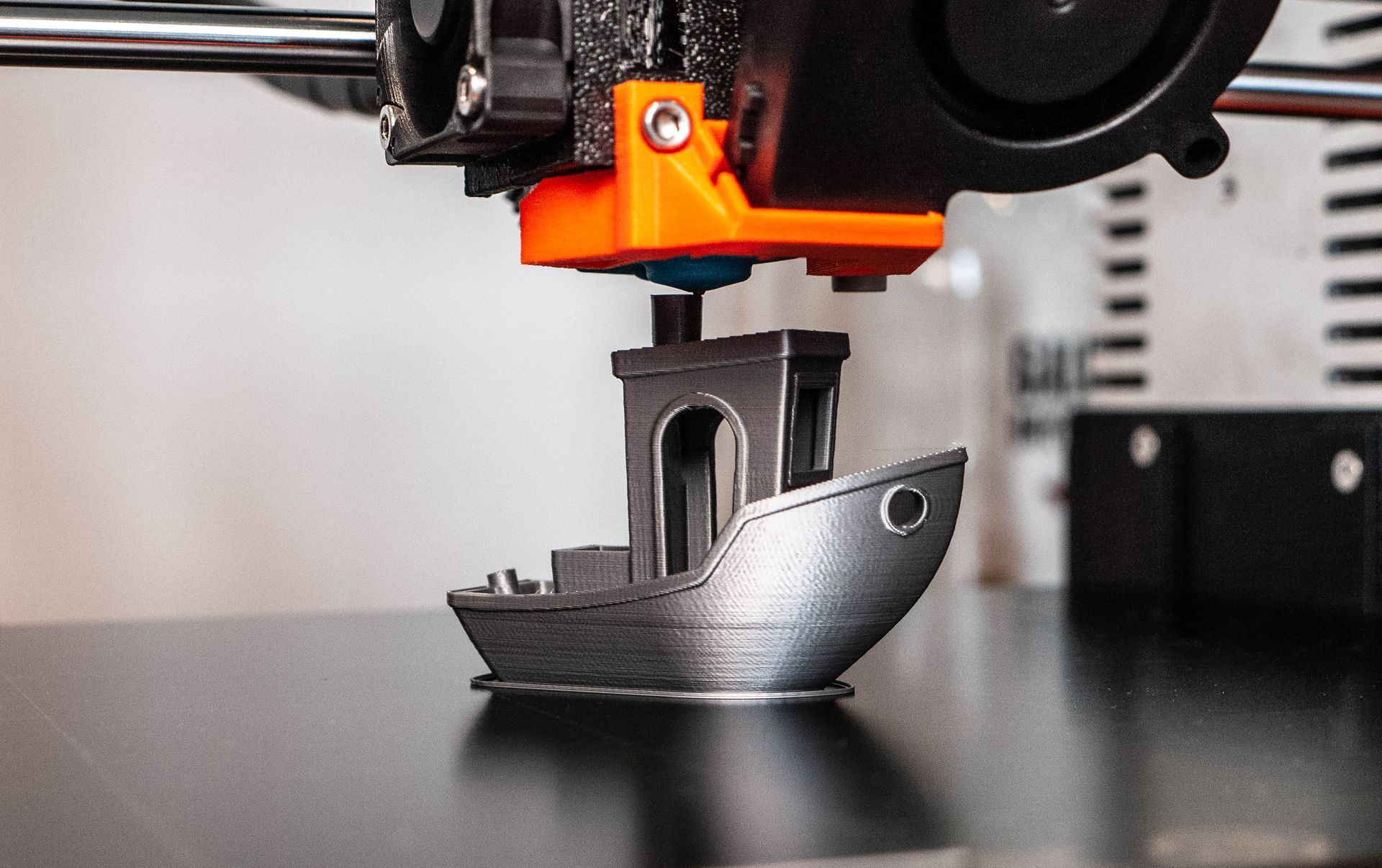

Model 1, based on PBF technology, offers exceptional climate suitability for Phoenix. The powder bed acts as an insulator, ensuring even cooling and minimizing warping in high temperatures. The enclosed build chamber further enhances its performance by shielding prints from ambient temperature fluctuations, making it an excellent choice for demanding printing environments. With compatibility for a wide range of materials, including heat-resistant options, Model 1 ensures reliable and high-quality results even in Phoenix's arid climate.

Model 2: Performance In High Temperatures

Model 2 works great in high-temperature areas. This makes it an excellent choice for 3D printing in Phoenix. Here are its main features and how they fit with the heat:

- SLS Technology: This printer uses Selective Laser Sintering (SLS). It uses a strong laser to melt powdered material. This makes strong and durable parts that can handle high temperatures.

- High-Temperature Resistance: It works with heat-resistant materials like Nylon 12 and glass-filled Nylon. This helps the prints stay strong and keeps their shape, even with the extreme heat in Phoenix.

- Minimal Warping: The SLS technology and the printer's precise temperature control lower the chances of warping. This is very helpful in hot weather, where uneven cooling can cause shape issues.

Because of these features, Model 2 is a great fit for printing in Phoenix. It provides reliable performance, reduces warping, and makes high-quality items even in tough temperatures.

Conclusion

To do well in 3D printing in Phoenix, it's important to understand how dry heat affects materials. You also need to adjust your methods. FDM and SLA printing technologies are known for their strength here. The printers suggested by By3Design are designed to work best in Phoenix, giving you great performance and lasting quality. Choose these top options to improve your 3D printing experience in the dry air of Phoenix. If you need help picking the right 3D printer for you, contact By3Design today.

By3Design Blog