The Future Of 3D Printing: By3Design's Expert Guide

The world of printing technology is changing fast, and Arizona (AZ) is leading the way in these new developments. 3D printing, or additive manufacturing, is changing how products are designed and made. This innovative technology allows businesses to create prototypes, functional parts, and finished goods with great accuracy and speed, often in just a few business days.

Evolution Of 3D Printing Technology In Arizona

Arizona has seen an amazing change in 3D printing. The technology has moved from being a special idea to a common manufacturing option. At first, 3D printing was mainly used for making prototypes and models. But now, thanks to better materials and printing methods, it can support large-scale production.

This growth has opened up new uses in different fields like aerospace, automotive, healthcare, and consumer goods. As businesses in Arizona take advantage of the power of 3D printing, the state is set to strengthen its role as a center for advanced manufacturing.

From Prototyping To Full-Scale Production

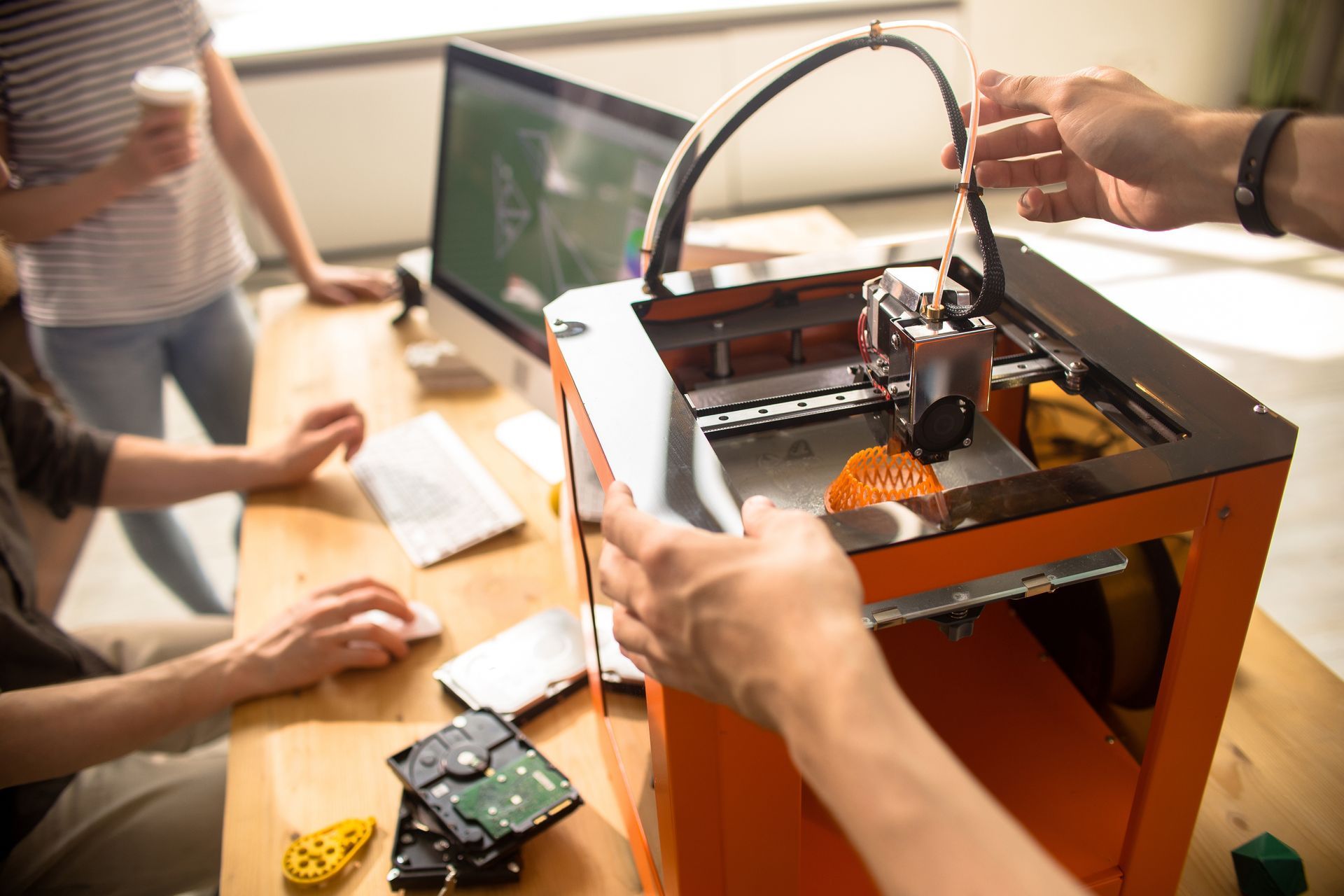

One big change that 3D printing has brought is to the product development process. Before, making a prototype took a lot of time and money. It often needed special molds or tools. With 3D printing, businesses can make prototypes quickly from digital designs. This faster process helps them improve and finalize products more efficiently.

As 3D printing has improved, it's not just about making prototypes anymore. Now, it helps with full-scale production runs too. This is great for companies that want to create specialized or custom products in small amounts. Traditional manufacturing often finds it hard to be cost-effective for these specific needs.

In contrast, 3D printing works well in these situations. It helps businesses meet the unique demands of customers while keeping costs down. This flexibility has opened up new ways to innovate and customize products.

Impact On The Local Economy and Job Market

The growth of 3D printing in Arizona has greatly changed the local economy and job market. With more businesses using this new technology, they are offering new jobs for skilled workers. The need for engineers, designers, and technicians with skills in 3D printing is growing. This helps create jobs and improves the local economy.

Also, 3D printing helps new companies and small businesses in Arizona. Its low cost and easy access give entrepreneurs a great way to make their ideas real. They can create products without spending a lot of money. This helps make a lively and varied business scene in the state.

In short, the spread of 3D printing in Arizona benefits the local economy. It encourages new ideas, draws in business investments, and increases the skilled workforce.

Major 3D Printing Techniques And Their Applications

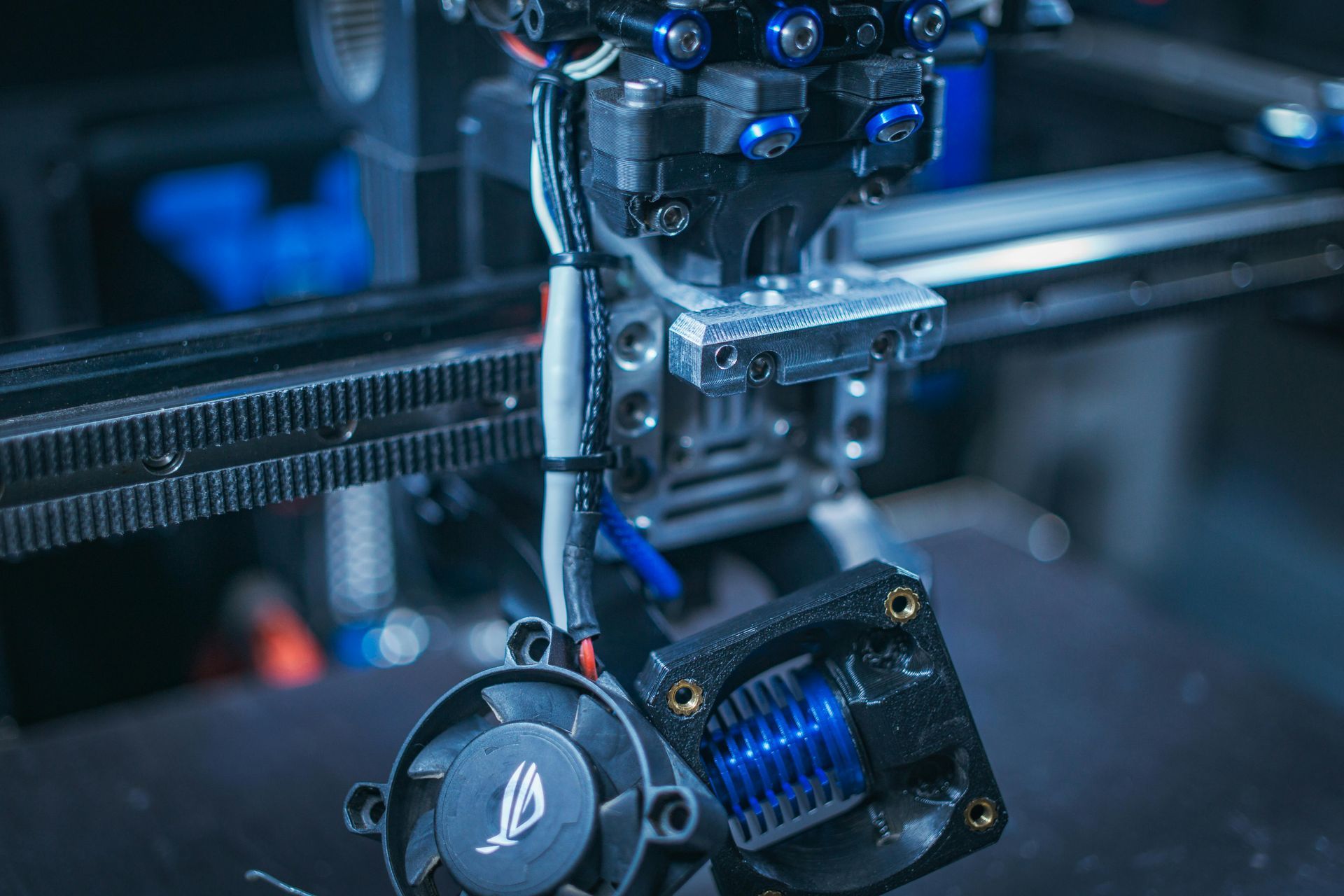

The world of 3D printing includes many methods, each with its own benefits and suitable uses. Three main techniques have become popular: Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). These methods are different in how they work, the materials they use, and how detailed their results can be.

FDM is often chosen for being affordable and easy to use. SLS stands out for making strong and long-lasting parts. SLA is known for creating very detailed and complex designs. The technique you choose will depend on what you need for your project, such as the materials, how clear you want it to be, and how many items you need to make.

Fused Deposition Modeling (FDM) For Consumer Goods

Fused deposition modeling (FDM) is a great choice for making consumer goods. It is affordable and flexible in product development. Using FDM technology, businesses in Arizona can quickly create functional parts. These parts have high resolution and low prices. FDM also has short printing times. It can print with different materials like nylon. This makes it a good option for rapid prototyping and manufacturing. Companies in Phoenix can take advantage of FDM. They can efficiently create customized fixtures and parts with complex geometries.

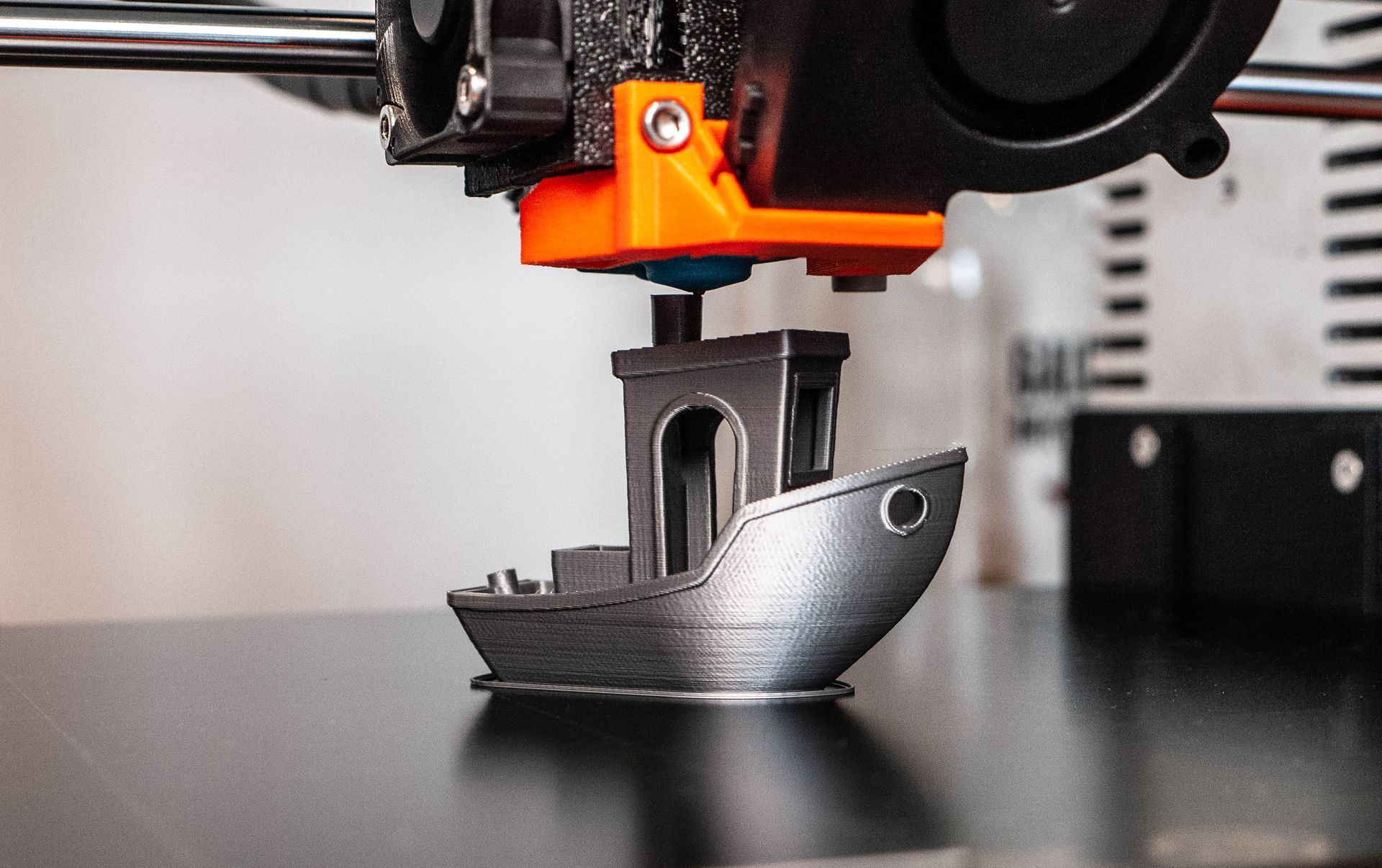

Selective Laser Sintering (SLS) In Aerospace And Defense

Selective Laser Sintering (SLS) is changing the aerospace and defense industries in Arizona. This new printing technology helps make functional parts quickly. It can create complex shapes and strong fixtures. SLS printers in Arizona offer high-quality prints using materials like nylon, which are great for aerospace needs. By using SLS for prototypes and final parts, businesses can speed up their product development and easily meet tight deadlines.

Stereolithography (SLA) For Medical Devices

Stereolithography (SLA) is changing how medical devices are made in Arizona. It provides high resolution and fast completion times. SLA also allows for detailed shapes and functional parts that are important in medicine. In Phoenix, medical professionals can quickly create and produce customized fixtures with great accuracy using SLA technology. Whether they need prototypes or final parts, SLA in Arizona gives a smart and affordable way for medical product development. It helps ensure good quality and efficiency.

By3Design's Pioneering Projects In Arizona

By3Design is a top 3D printing service in Phoenix, Arizona. They are leading the way in additive manufacturing. They focus on innovation and have a strong understanding of different 3D printing methods. By3Design works on many exciting projects that show how powerful this technology can be. Discover Choosing The Right 3D Printing Filament: By3Design Guide today!

Their work covers many areas, including automotive, architecture, and sustainable design. Let’s explore some amazing ways By3Design is changing the future of 3D printing in Arizona.

Custom Automotive Parts Manufacturing

By3Design is changing the game in Phoenix with its skills in 3D printing Arizona automotive parts. The company can make custom components, prototypes, and tools very quickly and accurately. This ability is popular with car makers and fans. Using CAD designs, By3Design can turn even the most complicated automotive ideas into reality.

From detailed interior parts to unique grilles and aerodynamic prototypes, By3Design’s 3D printing lets car designers use their creativity in new ways. Their quick prototype production means designs can be tested and improved faster, speeding up the whole process.

Additionally, By3Design places a strong focus on high-quality materials. This ensures their 3D printed automotive parts meet the tough standards of the industry. Their commitment to quality and precision has made By3Design a trusted partner for all things automotive in Arizona.

Architectural Models And Construction Solutions

By3Design is changing how architects and construction workers in Arizona think about design and project visuals. They use 3D printing to create detailed architectural models. These models help people see and understand complex designs better. They show spatial relationships, looks, and structure. Clients gain a clear view of their projects, while architects can improve their designs and make better use of spaces.

However, By3Design does more than make architectural models. They are also leaders in using 3D printing to create building parts, custom molds, and new construction ideas. The chance to print on-demand and cut down on waste opens exciting doors for future construction in Arizona.

As 3D printing technology keeps improving, we can expect By3Design to play an even bigger part in changing architectural design and construction methods in AZ and beyond.

Innovative Approaches To Sustainable Design

By3Design is very dedicated to eco-friendly design. They see 3D printing as a great way to help the environment. The company often tests new materials, like biodegradable plastics and recycled items, to make products that are good for nature. By improving designs to use less material and cutting down waste with on-demand manufacturing, By3Design wants to have a smaller impact on the planet.

They also look at complex shapes and light structures to support their sustainability efforts. By using less material and focusing on strength, By3Design makes products that are both good for the environment and perform well.

This commitment to being eco-friendly serves as an example for the industry. It shows how new manufacturing methods like 3D printing can help create a more sustainable future. By3Design's focus on material innovation and responsible practices makes them a strong supporter of sustainability in the 3D printing field in Arizona.

Overcoming Challenges In 3D Printing

3D printing changes how things are made, but it still has some problems. Like all new technology, 3D printing needs to work through challenges. Two major issues are the need for new materials and the difficulty of making a lot of products while keeping a good quality.

To get the full benefits of 3D printing, we have to solve these problems. This will help it be used more in different industries.

Material Innovation And Sustainability

The variety of materials that can be used in 3D printing has grown a lot. Now, it includes metals, plastics, ceramics, and even composites. Still, finding new and creative materials is very important for researchers and manufacturers. Creating materials that are stronger, lighter, and more adaptable will help 3D printing be used in more ways.

For example, making high-performance polymers that can handle very high temperatures or have special features like electrical conductivity or biocompatibility will unlock new possibilities. Another important part of improving materials is sustainability.

Researchers always look for eco-friendly options, like biodegradable polymers or materials from renewable sources. One good example is the creation of sustainable nylon filaments for FDM printing, which is a great step forward.

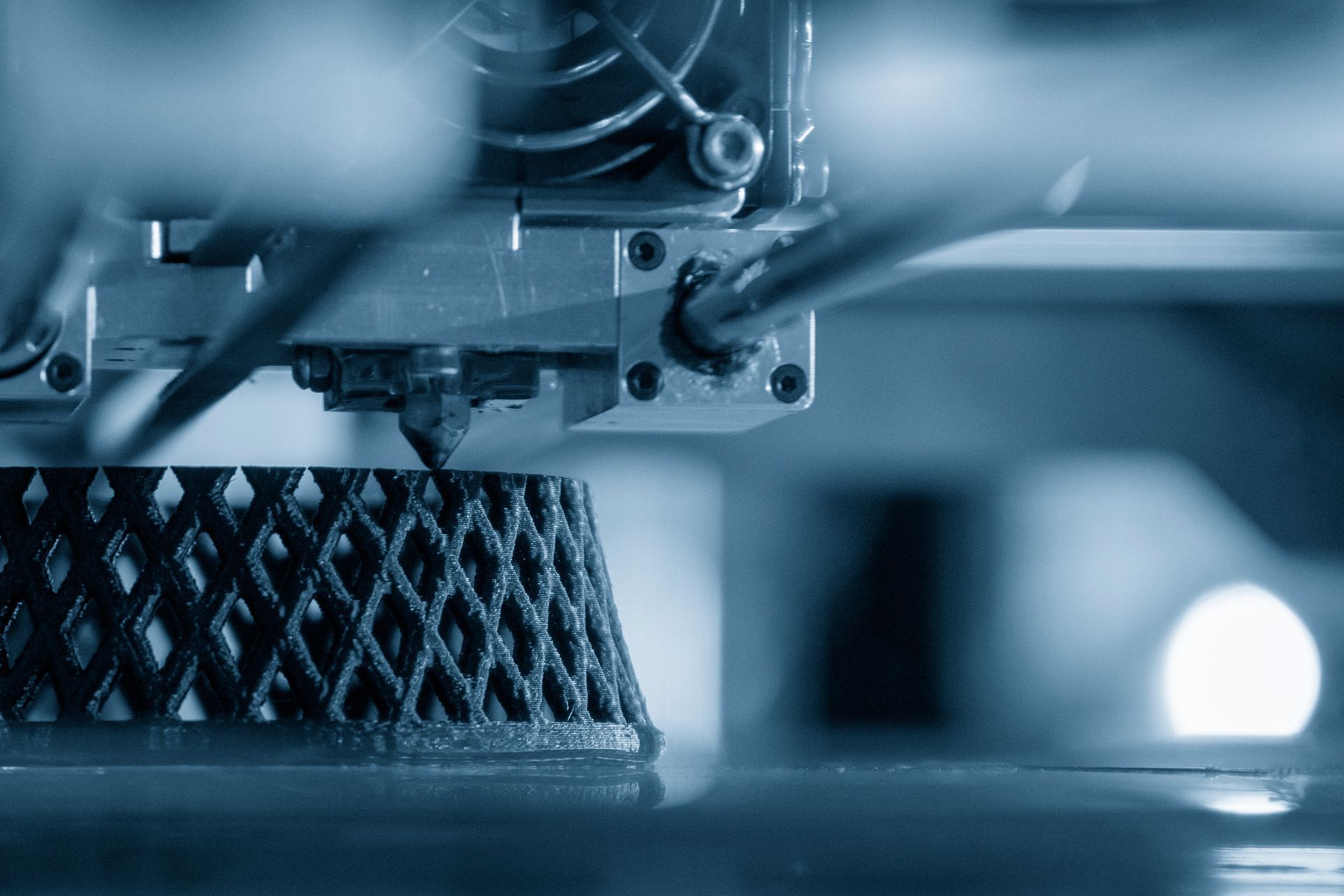

Scaling Production While Ensuring Quality

Scaling up 3D printing from making prototypes to mass production comes with different challenges. 3D printing does a great job of creating custom or small-batch items. However, to meet high demand, companies need to think carefully about several factors. One key factor is the build volume of 3D printers.

Having a larger build volume lets you produce more parts at once, which improves efficiency. But, keeping quality consistent over a big build volume needs careful calibration and close monitoring. Another important point is the automation of post-processing steps. When production numbers go up, tasks like removing support structures or finishing surfaces can slow things down.

Creating automated solutions for these jobs is vital to making production smoother and ensuring quality. By tackling these challenges, the industry can fully use 3D printing for large-scale manufacturing.

Conclusion

The growth of 3D printing in Arizona is changing many industries and helping the local economy. New methods like Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA) are making a big impact from making prototypes to full production. By3Design is taking the lead with exciting projects in custom car parts, architectural models, and eco-friendly designs. There are some challenges in finding new materials and increasing production, but the future looks bright. If you want to learn more about 3D printing and take your projects to the next level,

reach out to By3Design today.

By3Design Blog