3D Printing Prototype Service Accelerate Product Development

In today's fast-moving business world, it's very important to launch a new product quickly and efficiently. That’s why having a good prototyping service is essential. Prototyping, especially with new methods like additive manufacturing and rapid prototyping, helps businesses transform their product ideas into real items. This process allows for making design improvements and reducing risks before starting mass production.

The Role Of Prototyping In Product Development

Prototyping is a key step in creating a product. It connects the design phase with production. Engineers and designers can build physical models of their ideas. This helps test how well things work and spot possible design issues early. This step allows for new ideas and lowers the chances of expensive mistakes later in the process.

Prototypes are also great for sharing information and teamwork. They give a clear example for everyone involved, making it easier to understand. This way, people can give feedback and make sure they all agree on what to do next.

Understanding The Basics Of Prototyping

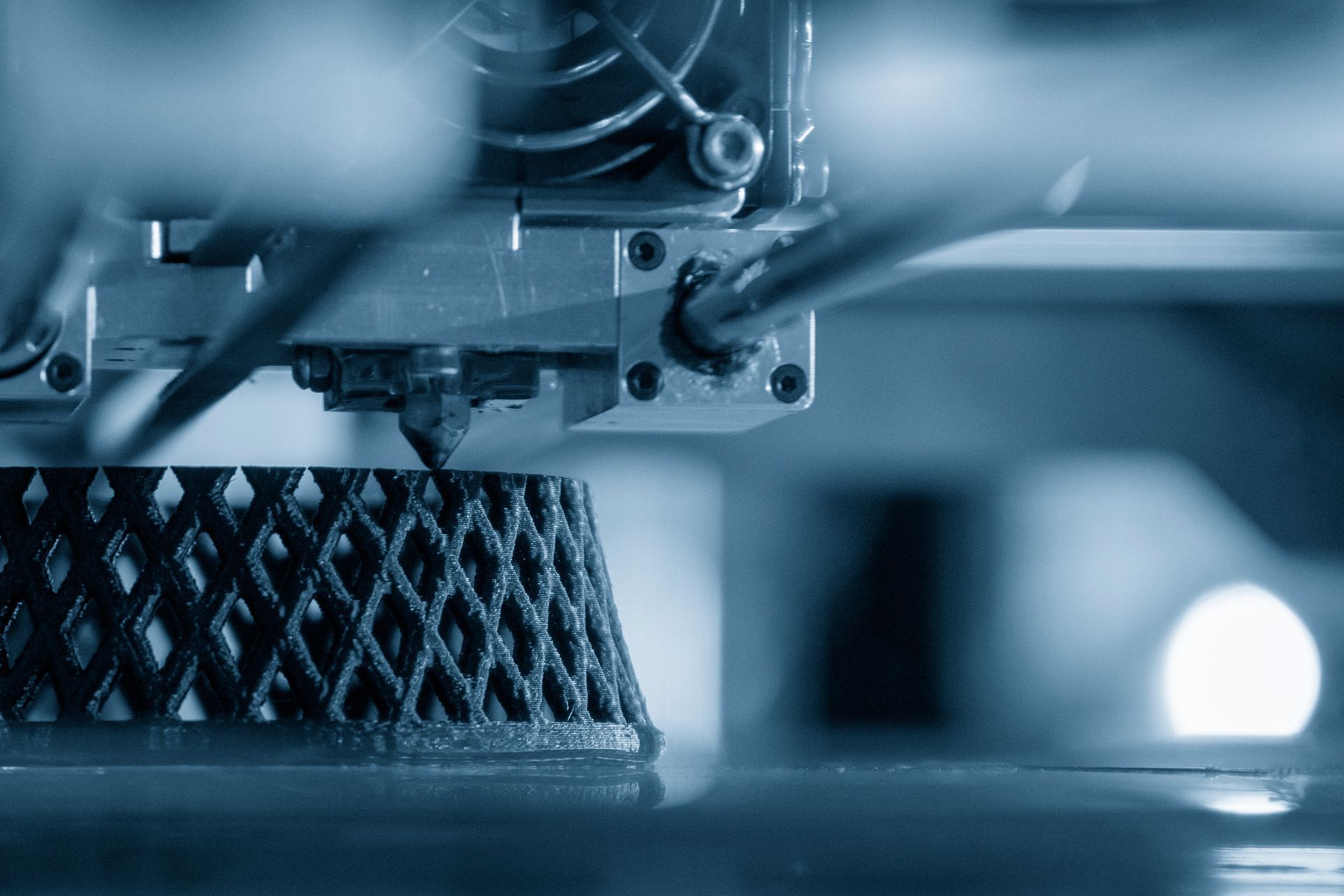

Prototyping includes different techniques and technologies. Each one is suited to specific needs and stages of the design process. Some of the most common methods are SLA (Stereolithography), SLS (Selective Laser Sintering), and SLM (Selective Laser Melting) and FDM (Fused Deposition Modeling). SLA uses a UV laser to harden the surface of liquid thermoset resin, creating detailed prototypes. SLS uses a laser to fuse powdered material, making durable and functional parts. FDM pushes out thermoplastic filament layer by layer, providing a low-cost way to create models and prototypes.

Choosing a prototyping method depends on factors like material needs, detail level, and budget. SLA works best for prototypes with complex designs and smooth surfaces, making it great for medical devices and consumer electronics. SLS is best for creating functional prototypes and parts that can handle high stress and heat, often used in the automotive and aerospace industries. FDM is a flexible and widely available choice for models, prototype testing, and low-volume productions.

Knowing the details of each method helps businesses choose the right one. This way, they can get the prototypes that meet their specific goals.

How Prototyping Integrates With The Design Process

Modern prototyping services work well with the current design process. They make it easier to change digital models into physical prototypes. CAD files, often saved in STL format, are the foundation of modern design and are used as inputs for these services. Using technologies like 3D printing, designers can directly turn CAD designs into physical prototypes. This ensures that the designs are accurate and speeds up the process of making changes.

This integration supports a design approach where changes can be made easily to the digital model. These changes quickly appear in the next prototypes. This not only speeds up the whole design process, but it also lets designers explore more options and improve the designs, which leads to better products.

With this integration, businesses can take advantage of rapid prototyping. This helps them improve their product development time and allows them to get their products to market faster.

The Evolution Of Prototyping Services

Over the years, prototyping services have changed a lot. This change is due to new technology and a growing need for quicker and easier product development. The industry has moved from old methods like hand-crafting and machining to modern techniques like 3D printing and rapid prototyping.

This shift makes prototyping faster and easier to access. It also allows businesses to develop complex and functional prototypes, speeding up their product development even more.

From Traditional Methods To Advanced Technologies

Traditional prototyping methods can still be used in some situations, but they often take a lot of time and hard work. Now, with the rise of additive manufacturing, which is known as 3D printing and injection molding, prototyping has changed significantly. This new method helps create complex shapes quickly and accurately.

Technologies such as Selective Laser Sintering (SLS) have made a big difference. They allow for the production of strong prototypes from various materials, like nylon, resulting in durable parts that are ideal for testing and even final product use. This move to digital manufacturing has sped up the prototyping process and lowered costs. Because of this, more businesses can benefit from it.

The growth of prototyping services shows how manufacturing technologies keep changing and improving. Their impact is significant as they help speed up how products are developed in different industries.

The Impact Of 3D Printing On Prototyping

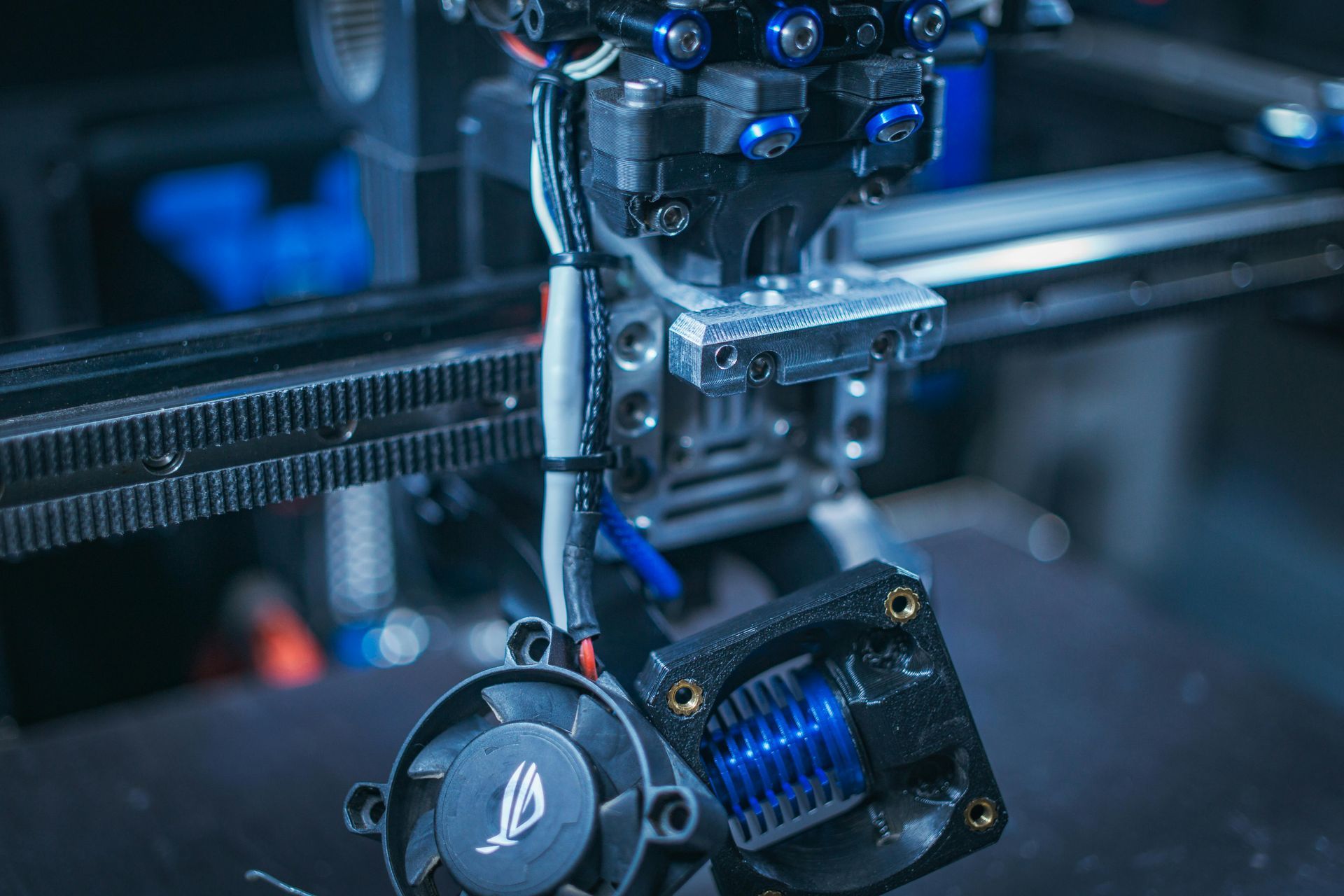

3D printing, also called additive manufacturing, has changed how we make prototypes. It works by adding material layer by layer. This method lets us create complex designs straight from digital files. As a result, we can make items faster and improve them quickly.

3D printing is flexible and works with many materials. These include , including plastics like ABS, ASA, and nylon, as well as resins and metals. using a 3D printer. This means we can create prototypes that act just like the final product. This helps us test and validate them more realistically.

Additionally, 3D printing prototype service cuts out the need for costly tools. This makes it a cheaper way to create prototypes, especially for small batches or unique designs.

Why By3Design Stands Out

By3Design stands out among prototyping services because of its strong focus on quality, speed, and keeping customers happy. The company makes custom parts using different advanced methods, like 3D printing and CNC machining, including single prototypes.

What makes By3Design special are its many choices of materials, finishes, and fast delivery times. This helps businesses move quickly to get their products on the market. Plus, By3Design has a team of experts who give personal support during the whole prototyping process. This starts with design help and goes all the way to production and shipping.

This focus on customers, paired with top-notch capabilities, makes By3Design a trusted partner for businesses that want to speed up their product development process.

Key Benefits Of Using Prototyping Services

Integrating prototyping services into the product development process offers many benefits. Working with a good prototyping service speeds up design and lowers the chances of making expensive mistakes or delays. This leads to getting products to market faster, which helps businesses stay ahead of competition and better meet customer needs. Discover 3D Design Consulting And Generative Design: By3Design Guide today!

Besides the practical benefits like speed and efficiency, prototyping services promote a culture of innovation in companies. They allow for real experimentation and checking designs. This helps businesses explore new ideas and provide great value to their customers.

Speeding Up The Product Development Cycle

One big advantage of using prototyping services, particularly our 3D printing service, is that they speed up product development. Traditional manufacturing can take a long time, especially for complex designs. With rapid prototyping methods like 3D printing, businesses can cut down on that time. They can make changes to designs and test new versions in just days.

This quicker development process helps companies launch their products sooner. This way, they can get ahead of the competition and gain market share faster. Shorter prototyping cycles also mean less time spent in development, which usually leads to lower costs. This saves valuable resources for other important areas of the business.

By using rapid prototyping services, companies can make their product development smoother. They can also adjust better to changes in market needs or customer feedback.

Types Of Prototyping Services Offered By By3Design

By3Design offers a wide variety of prototyping services for different project needs. This can include simple concept models and more advanced functional prototypes. It is important to understand the unique requirements of each project. The expert team at By3Design works closely with clients to help them choose the best service for their needs.

This personalized approach makes sure that clients get prototypes that fit their specific needs and budget. It also helps them get the most value out of their investment in the prototyping process.

Rapid Prototyping Techniques

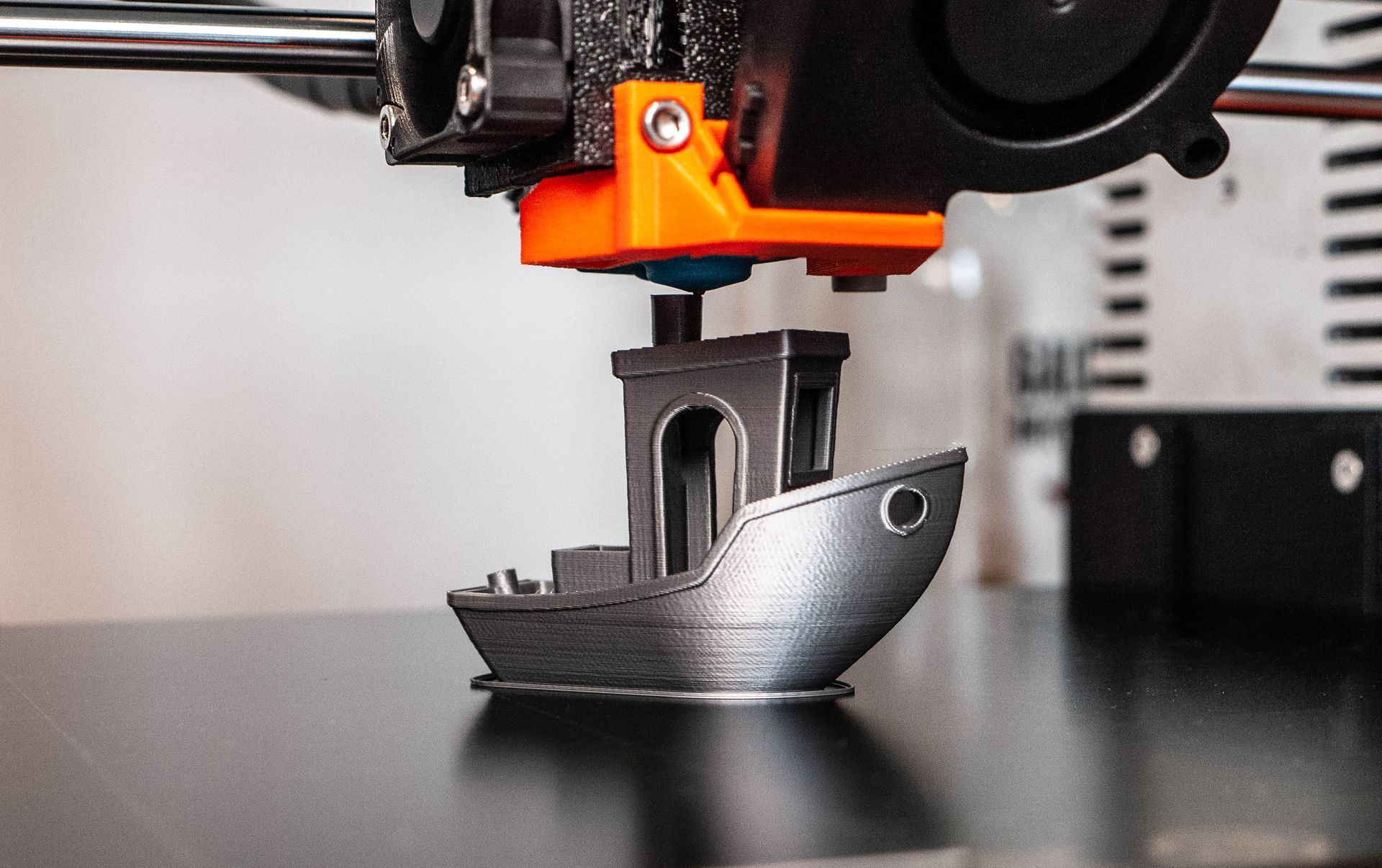

By3Design is great at rapid prototyping. They help businesses change their digital designs into physical prototypes quickly. Using the latest 3D printing technology, By3Design can create detailed and complex prototypes in just a few days. This speeds up the design process a lot.

Their online platform has a feature for an instant quote on fixtures. Clients can upload design files and get quick prices and lead time estimates. This clear and quick process helps businesses to plan their prototyping projects and budget better.

By3Design focuses on speed and accuracy. This means clients get their prototypes fast. It helps them validate their designs quicker, cut down on development costs, and bring their products to market faster.

High-Fidelity Prototypes For User Testing

By3Design does more than just rapid prototyping. They create high-fidelity prototypes that look and work a lot like the final product. These prototypes are key for effective user testing.

When users have a realistic model of the product, businesses can get important feedback. This feedback covers usability, comfort, and overall design. It helps find any design problems before moving to mass production.

With thorough user testing of high-fidelity prototypes, companies can reduce the risk of expensive changes later on. This step-by-step method, supported by By3Design's advanced prototyping skills, results in better and more user-friendly products.

Choosing The Right Prototyping Service For Your Project

Choosing the right prototyping service is very important for the success of any product. Businesses must think about several factors. These include their project needs, budget limits, how detailed they want the prototype to be, and the skills of the prototyping partner.

It's important to understand different prototyping technologies like SLA, SLS, FDM, and PolyJet for creating plastic parts to make good choices. Working with a trusted prototyping service like By3Design gives access to expert help and many prototyping options. This way, businesses can find the best solution for their specific needs.

Conclusion

Prototyping services are very important for speeding up product development. They also improve accuracy and help save money. By3Design offers great solutions for many types of projects. They provide everything from quick techniques to detailed prototypes for user testing. Their services are top-notch in the industry. Using new technologies like 3D printing has changed old ways of making prototypes. If you want to make your product development faster and more efficient, By3Design's skills can help you a lot. Choosing the right prototyping service is key to making your project successful.

Contact

By3Design today to take advantage of their creative solutions and move your product development forward.

By3Design Blog