Rapid Prototype 3D Printing: Latest Innovations

In today’s quick-moving business world, rapid prototyping is very important for product development. It helps companies check designs, test how things work, and make needed changes before starting full production. Additive manufacturing, also known as 3D printing, has changed rapid prototyping. It gives product developers a strong tool to turn their ideas into real products quickly and at a lower cost.

Understanding 3D Printing Technologies In Rapid Prototyping

3D printing includes different technologies. Each one uses its own method to make three-dimensional objects from digital designs. These technologies differ a lot in materials, resolution, and cost. Choosing the right technology is important. It affects the prototype’s features and how good it is for the task it needs to perform.

For example, Fused Deposition Modeling (FDM) is popular because it's cheap for making simple prototypes. On the other hand, Stereolithography (SLA) is great for creating detailed designs with high resolution.

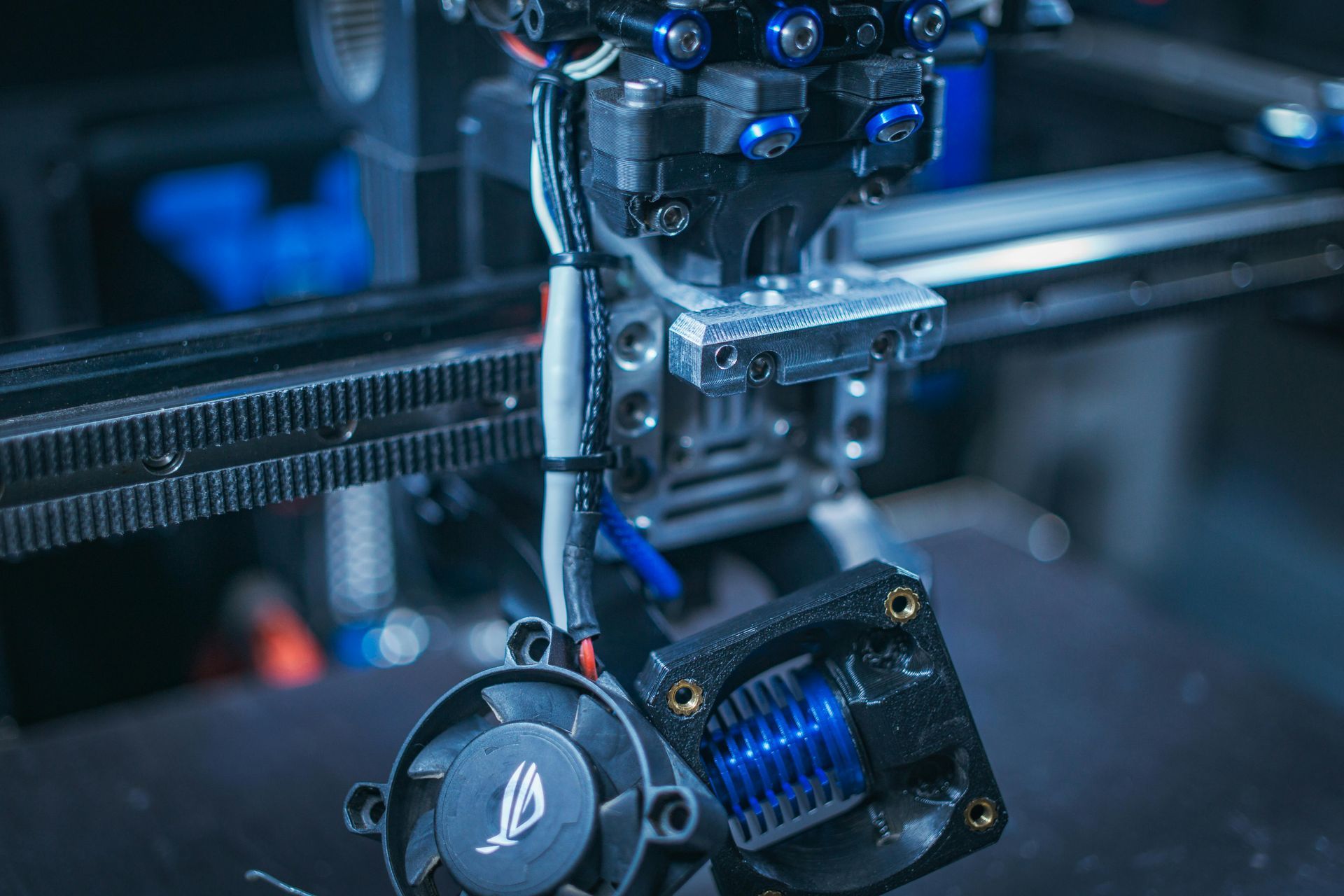

Overview Of Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a popular method of additive manufacturing. It helps create quick prototypes. In this process, thermoplastic filaments are heated and squeezed out to form layers. These layers build a three-dimensional object. FDM is cost-effective, so many product development teams choose it. This method allows for fast testing of functional prototypes. It also enables easy changes through quick iterations before moving forward to large-scale production. FDM has many types of thermoplastics. Each has different mechanical properties to fit the needs of the final product.

Advantages Of Stereolithography (SLA) In Prototyping

Stereolithography (SLA) is great for making detailed and smooth prototypes. It can create complex shapes that traditional methods, like injection molding, can't match. SLA helps speed up product development by reducing lead times, which is helpful for product development teams. The materials used in SLA create strong and functional parts that can be used as needed. With SLA, you can get quick quotes and low prices, making it a good choice for rapid prototyping, especially for high-accuracy functional prototypes.

Material Choices In 3D Printing For Prototyping

The choice of material is very important for 3D-printed prototypes. It affects how they work, how they look, and how well they perform. Thanks to progress in material science, we now have many different options. Each material has its own traits that fit various needs. For example, ABS and Nylon are strong, while PolyJet materials allow for printing with multiple materials. So, picking the right material properties is crucial.

To choose the best material, you need to understand how you’ll use the prototype 3D printing and what qualities you want. This will help ensure the final product mirrors real-world situations. It will also give valuable insights during testing and evaluation phases.

Using ABS And Nylon For Durable Prototypes

ABS and Nylon are two popular materials used in 3D printing. They are known for being strong, durable, and having good temperature resistance. ABS stands for Acrylonitrile Butadiene Styrene. It is a thermoplastic often used in FDM 3D printing. ABS is impact-resistant, making it great for making enclosures, snap-fit parts, and functional parts.

Nylon is a synthetic polymer loved for its toughness and flexibility. This makes Nylon perfect for prototypes that need to resist wear, like gears and hinges. Moreover, Nylon has excellent chemical resistance, which expands its use in many industries.

The strength and flexibility of ABS and Nylon make them great for prototyping. They help create durable prototypes that can handle testing and mimic real-life conditions well.

The Role Of PolyJet Technology In Multi-Material Printing

PolyJet technology has changed 3D printing. It lets users create prototypes with different materials and material properties all in one print. Unlike regular methods, where parts are printed separately and put together later, PolyJet smoothly combines various materials with different features, such as how strong or flexible they are, into one prototype. This new way of printing uses a process like inkjet printing.

In this method, tiny drops of liquid photopolymer are sprayed onto a building surface. They immediately cure with UV light. This ability to place different materials with unique qualities helps product developers make prototypes that look and work like the final product. PolyJet is popular in making complex assemblies, medical models, and detailed consumer products that need different material properties in one print.

PolyJet technology creates functional prototypes that can resemble the final products closely. It is excellent for prototyping, giving product developers an advanced way to leap from ideas to actual designs while taking material properties into account. This shows how important PolyJet is in today’s 3D printing industry.

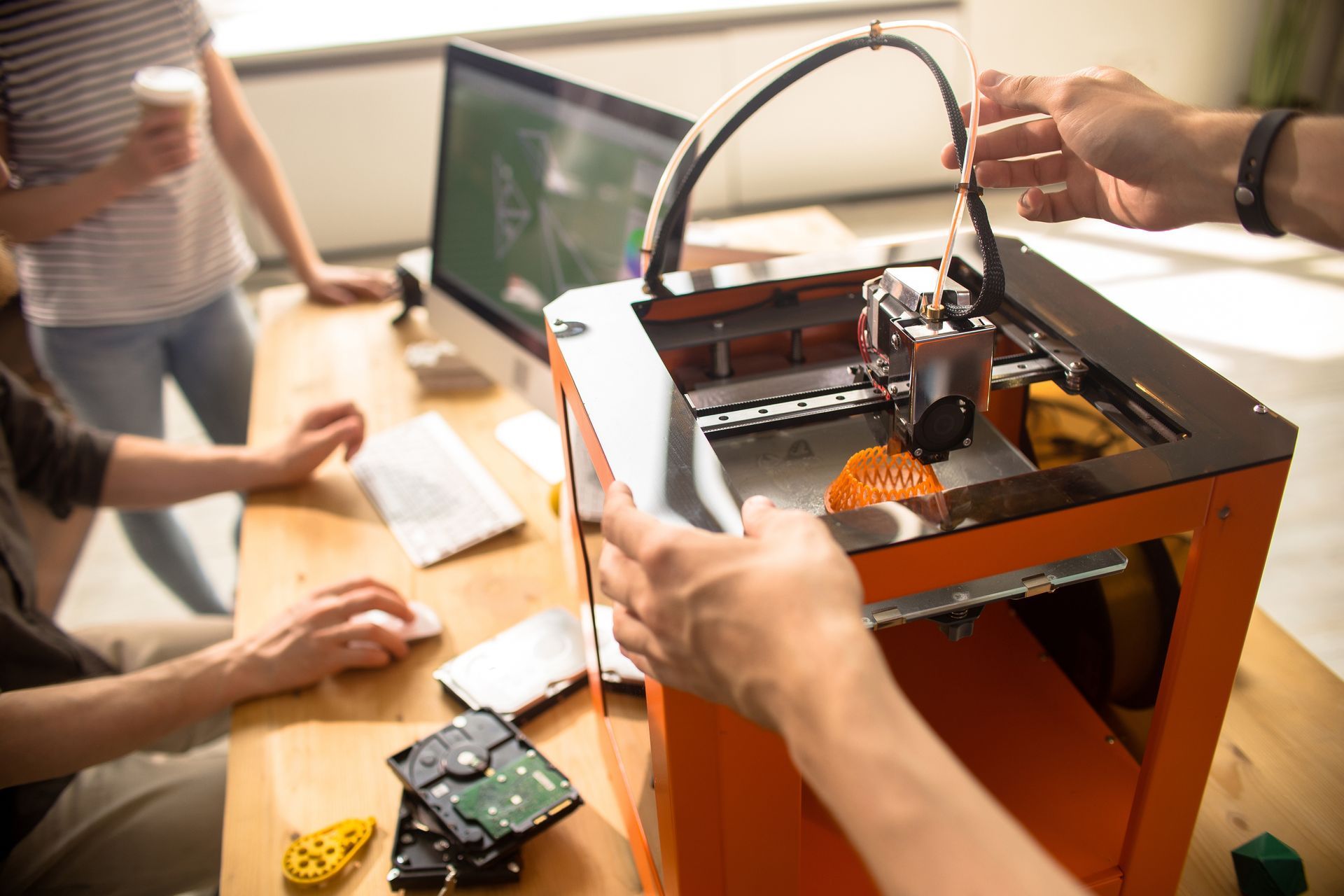

How 3D Printing Revolutionized The Prototyping Process

3D printing is a game-changing technology. It has changed how industries create prototypes. With 3D printing, designers can build physical objects right from digital files. This gives them more freedom in design. They can focus on new ideas without the limits of old manufacturing methods. As a result, projects are done faster, leading to shorter lead times in product development.

This quick production allows designers to make changes easily and fix problems early. It helps create better products in less time. Plus, using 3D printing cuts down on costs that are usually high with traditional prototyping methods, especially for complex designs and small production runs. See more on 3D Printing Prototype Service Accelerate Product Development.

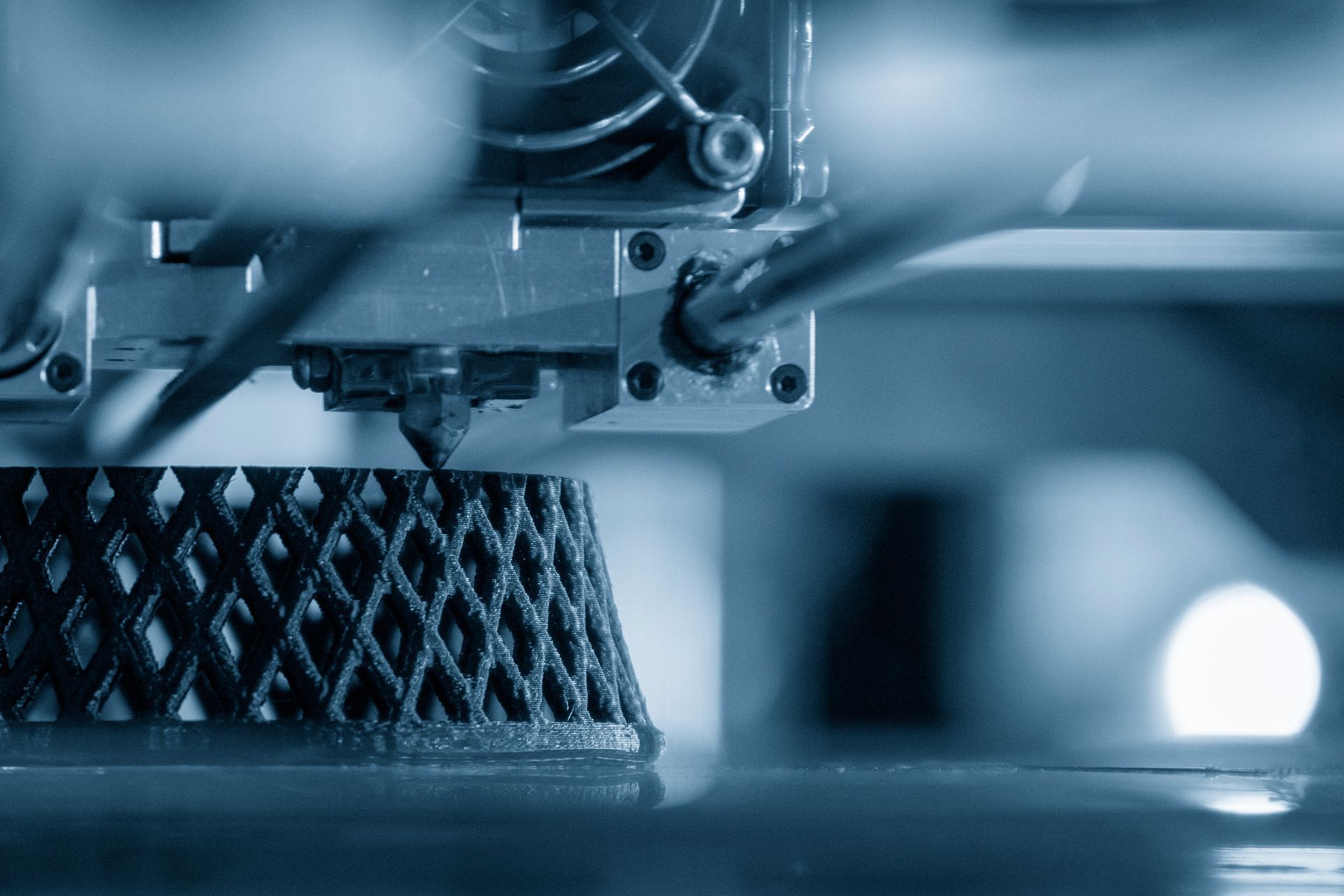

Advantages Of Using 3D Printing For Rapid Prototyping

One of the biggest benefits of 3D printing in rapid prototyping is that it can greatly shorten lead times. Unlike traditional methods that take a long time to set up and use complicated tools, 3D printing makes prototypes straight from CAD files. This means quicker production times.

Also, 3D printing allows the making of functional prototypes that look very much like the final product. With the ability to create detailed shapes and add complex features, engineers can check for fit, form, and how well things work. This helps to create better designs and limits expensive mistakes when it's time for mass production.

Lastly, 3D printing is a great option because of its affordable price. By cutting out costly tools, wasting less material, and needing less manual work compared to traditional methods, 3D printing offers a budget-friendly choice for businesses, big and small.

Comparison With Traditional Prototyping Methods

Traditional prototyping methods, such as injection molding and CNC machining, have been the cornerstone of product development for decades. While effective, these methods often involve high setup costs, extended lead times, and limited design flexibility, especially for complex geometries. 3D printing, in contrast, offers a compelling alternative that circumvents many of the limitations posed by traditional approaches.

Injection molding, while suitable for mass production, requires expensive molds and lengthy setup processes, making it cost-prohibitive for prototyping. CNC machining, while capable of high precision, is limited in its ability to create complex shapes and intricate internal features.

| Feature | 3D Printing | Traditional Methods |

|---|---|---|

| Lead Time | Days | Weeks to Months |

| Setup Costs | Low | High |

| Design Flexibility | High | Limited |

| Material Choices | Extensive | Limited |

Applications And Industries Utilizing 3D Printing For Prototyping

The wide use of 3D printing has made it popular for making prototypes in many industries. Product developers use additive manufacturing to speed up their design work, cut down costs, and introduce new products faster.

In the aerospace industry, 3D printing makes it easy to produce lightweight and complex parts, like air ducts, brackets, and engine components. The medical sector also benefits as it can create custom implants, surgical guides, and detailed models for planning surgeries. Besides these fields, 3D printing finds its place in sectors like automotive, consumer products, electronics, and industrial manufacturing.

The ability to produce prototypes with different materials and fine details is essential for product developers in various industries. This technique allows for the creation of end-use parts that are practical and functional.

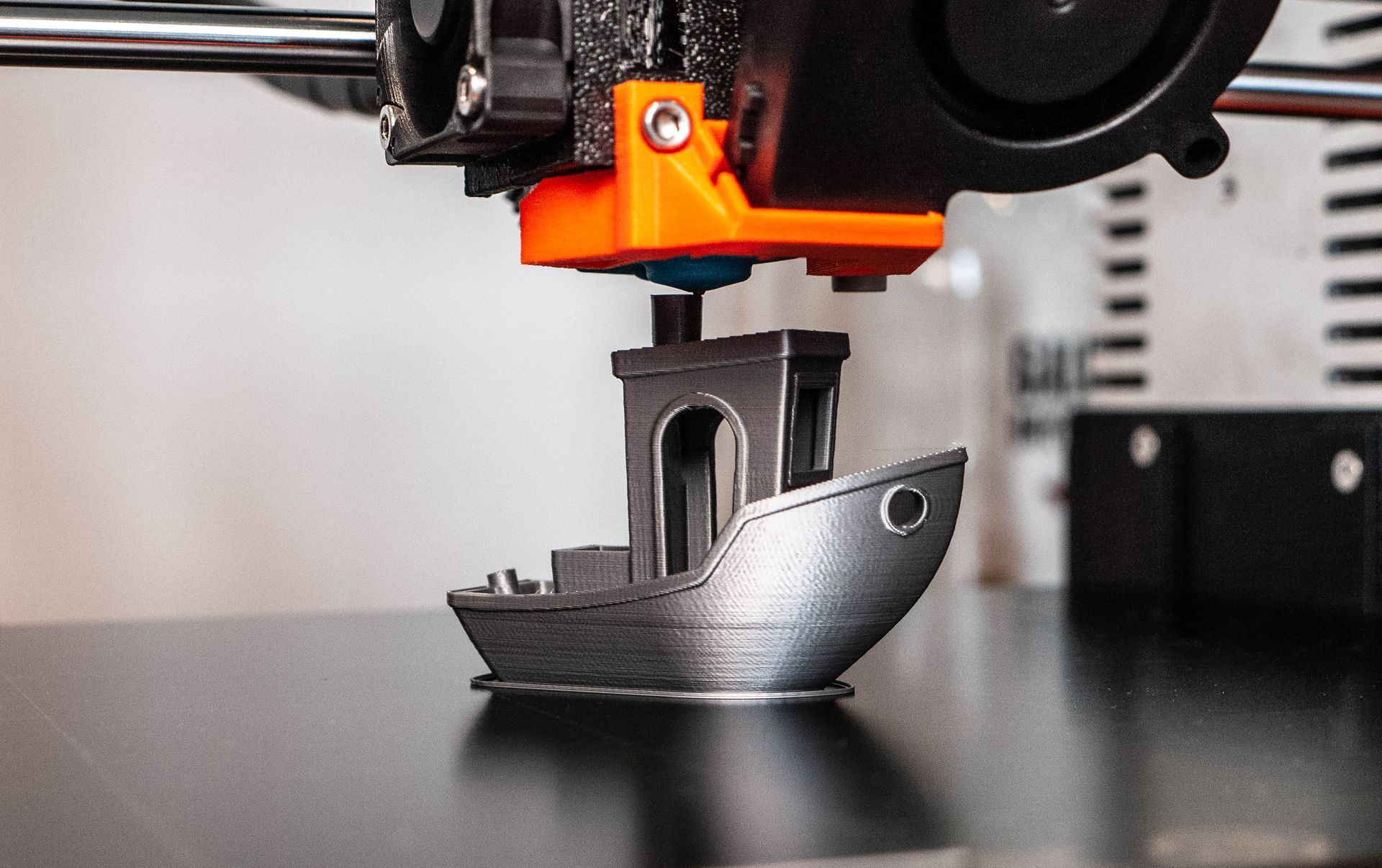

By3Design's Success In Rapid Prototyping

By3Design understands how important rapid prototyping is in today’s competitive market. We have helped many companies from different sectors use 3D printing to speed up their design cycles, improve their ideas, and create better products. Our team of skilled engineers and designers work closely with product development teams. We support them in the iterative process, taking them from the first concept to the final product.

With our advanced 3D printing technology, By3Design helps companies quickly test different iterations. This way, they can check their design choices and make smart decisions during the product development process. Our focus on rapid prototyping lets our clients bring their products.

Conclusion

The rapid evolution of 3D printing technology has revolutionized prototype development in various industries, including aerospace, medical, automotive, and more. By enabling swift iteration and testing of designs, companies like

By3Design are enhancing product development processes and accelerating time-to-market. Embracing 3D printing for rapid prototyping is not just a trend but a necessity for staying competitive in today's fast-paced business landscape.

Work with us today!

By3Design Blog